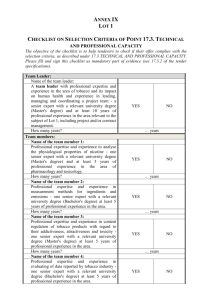

tender document - gear equipment final version

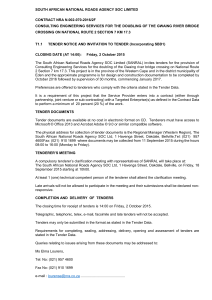

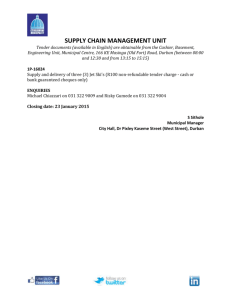

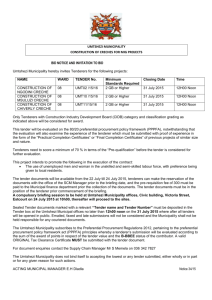

advertisement