JOHN DEERE COMPONENTS WORKS

advertisement

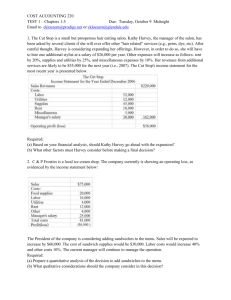

The following report is a consultation analysis of John Deere Component Works costing structure. Included is a discussion of the existing cost system as well as a comparison with the proposal of the Activity Based Costing system. The solutions to the required discussion issues have been thoroughly prepared and are hereby included. Problem Statement: The demand for John Deere Component Work’s (JDCW’s) products has suffered due to the collapse of farmland value and commodity prices. A number of continuous failures in JDCW’s competition for bids have placed an onus upon management to question its current costing methods. As a result, an analysis must be made regarding the current costing methods in order to determine their validity and to aid the company in adopting a more sound costing system. Analysis John Deere Component Works was a subdivision of John Deere and Company which dealt exclusively with the manufacturing of tractor component parts. By the mid 1980’s, JDCW found that its available excess capacity was increasing. To neutralize this problem JDCW attempted to take advantage of the efficiencies of its newly acquired automatic turning machines by bidding on parts offered from within the company. This lead to a direct bid of 275 of the 635 parts offered by John Deere and Company. Out of the possible 275 parts, JDCW was successful in the bidding of only 58 parts, which happened to be low volume parts. This became a concern for JDCW because its aim was to attain the bids that offered the higher volume parts, as to allow it to take advantage of its machine’s high volume efficiency. In reality, the problem for JDCW was not the number of bids they received, but the alarming discrepancy within its bid prices and that of its competitors. JDCW realized that something was wrong in their accounting system, and decided to review its current cost structures. The existing cost system is strong in that it is simple and easy to maintain. Overhead allocation was based on direct labor hours, machine hours and material dollars. The use of standard costs allows JDCW to compare actual labor overhead costs with budgeted rates in order to determine the following years’ overhead costs. In fact, the old cost structure worked quite well in the past since the company produced a specialized line of products that was periodically consistent. This in the aspect that the products differed little or not at all in both unit and volume. However, this cost method does not provide the best system for JDCW’s cost allocation. By using only three overhead rates the present system grossly undermines the true production costs since other activities of the production process are not acknowledged. The system also fails to compute material usage variances, which only further discredits the accuracy of the accounting 1 cost structure. For more accurate measure of material usage, the quality assurance department must include this variance calculation in its weekly report. A further weakness is that the accounting department issues reports that only indicate how each area operates, rather than evaluating the performance of each area, which would prevent a constriction in cost efficiency. These weaknesses prevent JDCW from accurately accessing its true costs. Essentially, with the current cost system, managerial analyses is highly flawed due to a lack of crucial in-depth cost information. Failures in the existing cost system are due to several factors. First of all, when JDCW calculates its standard direct labour, direct machine hours, and total overhead, the volumes are calculated on a long-term basis. However, if the actual production volume is not for the long term it becomes a problem, this in the sense that it is difficult to modify the system as to accommodate for any increases or decreases in the production demand. Secondly, when JDCW updates its overhead rates for the upcoming year, its forecasts are based on the previous years’ figures. This system is going to result in serious inaccuracies, especially when the company attempts to tackle production volumes that are completely “alien” to the companies’ historical production trends. An example being the bidding attempt on the 275 parts. This reflects the company’s constricted cost system that revolves around a limited product diversity trend, instead of allowing for a correct forecast of diverse products that more realistically represent the volatile demand of the industry. Hence, it would only be logical to state that the JDCW’s yearly updated overhead rates are inaccurately calculated. As foreshadowed, the standard accounting cost system used by the company is significantly out of date. This is because the system was originally designed to handle a direct labor intensive production process with little overhead costs. However, when the company changed its production process to a more automated system, it simultaneously increased its overhead costs. This dramatic overhead increase was embodied through increases in supervision, maintenance, electricity, and setups. Since more overhead costs were now being incurred, a new system had to be implemented to adapt to this new environment. These weaknesses further support the fact that JDCW’s bids were continuously miscalculated in relation to their competitors. Using the existing system, management at JDCW continually under-costs its low-volume parts and over-costs its high volume parts. If its bids were to be based on the ABC method, JDCW’s costs would be more accurate, and it would most likely acquire a higher number of bids. Since the production of low volume parts is less efficient than high volume parts, it is in the interest of JDCW to attain higher volume bids. However, since its Standard Cost system is flawed, the bid proposals submitted by JDCW are also flawed. To 2 clearly illustrate this point, a comparison of the two cost systems for part A103 highlights the discrepancy. Under the Standard Cost system, part A103 costs $22.80 while under the ABC method, the part costs $32.18. (See Appendix B) RECOMMENDATIONS It is imperative that JDCW change from Standard Costing to Activity Based Costing. This is essential because the Standard Cost system only works well in a stable production environment. With the advent of new technologies being employed at JDCW, the Standard Cost system is incompatible and therefore makes it difficult for JDCW to attain precise figures. The ABC method, on the other hand, provides management with more accurate cost allocations, enabling it to make bids that truly represent its production costs. Since the standard system bases its costs on volume related overhead rates, costs that are product-related, batch-related or facility sustaining are not accurately allocated. If total overhead costs are based solely on a volumerelated basis, distortions will result because not all costs are driven by production volume. (See Appendix A) With the ABC method, this problem is rectified. Since the ABC approach assumes that overhead costs can be traced directly to products, the total overhead costs are better allocated to the products, giving JDCW a closer indication of the behaviour of its overhead costs. The ABC method allows overhead costs to be assigned to products according to the proportion of demand that each product places on that activity. Hence, creating more accurate product cost estimates. In implementing an ABC system, mangers will be motivated to consider a different set of actions from that of the old cost system. They will be removed from relying solely on previous years figures and will most likely be involved in a more unstable production environment. Specifically, managerial decisions will include modifications of pricing, product mixes, and customer mixes; enhancing supplier and customer relations; improving the design of products and services; and performing activities more efficiently. Overall, managers that switch to an ABC approach will find the extra burden of planning and maintaining a wider variety of cost pools. SUMMARY AND CONCLUSION The issue that made JDCW question its cost structure is the fact that its bids on part productions were out of line with those of its competitors. A closer look at the problem reveals that indeed the Standard Cost system currently in place is outdated. A more accurate system is needed to remain competitive, and in this situation, the ABC approach is most commendable. 3 BACKGROUND The John Deere Company has been operating in the farm equipment industry for 162 years. John Deere Component Works was established as a separate division of the John Deere Company during the 1970’s as continued growth created the need for increased production space. JDCW had been structured to be a captive producer of parts for Deere’s equipment divisions, particularly tractors. Thus it had to produce a wide variety of parts whose volume was relatively low. Due to low capacity during the mid 1980’s, the Gear and Special Products Division of JDCW decided that complex machined parts offered a promising niche. Since this process required more automated machines, more overhead costs were to be incurred. As part of the strategy of the Gear and Special Products Division, it set out to market machine parts to the outside world. In order to obtain production orders Gear and Special Products decided to bid on 275 out of the 635 parts that Deere and Company offered. They soon found out, however, that its bid prices were not in line with those of its competitors, and since the key to successful competition in the outside world is price, JDCW had to rethink its pricing strategies. 4 APPENDIX A OVERHEAD COST POOLS Direct Labor Unit Machine Operations Unit Machine Setups Batch Production Order Batch Materials Handling Batch Parts Administration Product-Sustaining General and Administrative Facility-Sustaining 5 APPENDIX B STANDARD VERSUS ABC COSTING FOR PART A103 STANDARD METHOD Total Cost = Direct Labor + Direct Materials + Overhead Direct Labor = .185 labour hours x 12.76/hr = 2.36 Direct Materials = 6.44 Overhead = Direct + Period Direct Labour OH = 2.05 x .185 x 12.76 = 4.89 Machine Hours OH = 27.56 x .310 = 8.54 Materials Handling OH = .097 x 6.44 = 0.62 Total Cost (per 100 parts) $22.88 ABC METHOD Total Cost = Direct Labor + Direct Materials + Overhead Direct Labor = .185 x 12.76 = 2.36 Direct Materials = 6.44 Overhead: Labour Support OH = 1.11 x .185 x 12.76 = 2.62 Machine Operation OH = (8.99 + 6.71) x .031 = 5.15 Machine Setup OH = (33.76 x 4.2 x 2) / 80 = 3.54 Production Order OH = (114.27 x 2) / 80 = 2.86 Materials Handling OH = 19.42 x 4 = 0.97 Parts Admin. = (487 x 1) / 80 = 6.09 General and Admin. = (.091 x 12.76) x (.187) + 21.23 = 2.14 Total Cost (per 100 parts) $32.21 6