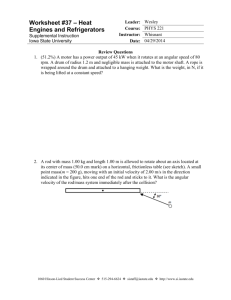

engine - interior

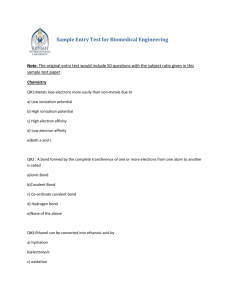

advertisement