ИЗУЧЕНИЕ ВЗАИМОДЕЙСТВИЯ СПЛАВОВ Pb

advertisement

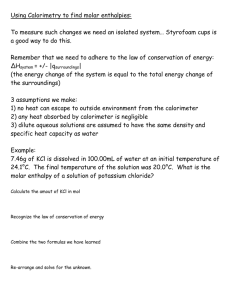

CATHODE PROCESSES IN KCl-PbCl2 MELT Yu.P. Zaikov1, P.A. Arkhipov1, Yu.R.Khalimullina2, V.V.Ashikhin2 1 The Institute of High Temperature Electrochemistry, Ural Branch of Russian Academy of Sciences, S. Kovalevskaya/Academicheskaya St, 22/20, 620990 Yekaterinburg, email:dir@ihte.uran.ru 2 Open Joint-Stock Company ELECTROMED, Scientific Research Centre, Lenin St, 1, 624091, Verkhnyaya Pyshma Technology of crude lead refining is developed in the Institute of High-temperature Electrochemistry. The crude lead was obtained from the car battery wastes. While organizing the refinement in the molten salts it is important to know deposition mechanisms [1] of lead ions in the chloride melts containing oxychloride complexes. It is necessary to study kinetics of electrode processes to understand this mechanism Many authors studied kinetics of electrode processes of lead electroreduction from chloride melts [2 – 10]. Diffusion coefficients of ions in molten salts were measured by using radioactive isotopes [10] and with the help of electrochemical parameters [2 -9]. V.P.Yurkinskyi, D.V. Makarov [2, 3] studied the mechanism and determined kinetic parameters of Pb(II) ion at electrochemical reduction process in various individual melts (NaCl, KCl и CsCl), as well as in mixtures with various component content using linear voltamperometry, chronopotentiometry and chronoamperometry methods. Studies of lead ions reduction in lithium, sodium, potassium and cesium chlorides showed, that cation composition causes significant influence on the process. Electrochemical reduction is limited by Pb 2+ diffusion in LiCl and NaCl melts, when in the potassium and cesium chlorides by chemical reaction of complex ion [PbCln]2-n. dissociation. Diffusion coefficient value was found to decrease and lead(II) ion diffusion activation energy to increase in the LiCl–CsCl row. Y.M. Rybuhin, E.A. Ukshe [4] measured lead ions diffusion coefficients in molten chlorides by chronopotentiometry method. Measurements were carried out under the argon atmosphere. The rectangular polished platinum plate about 1 cm2 square was used as the working electrode. Molten lead placed into the quartz tube, connected by capillary with the bulk melt was the anode and reference electrode. 186 NaCl, KCl, PbCl2 salts of chemically pure grade were used in the work. They were melted under vacuum before the experiment. According to the results of these studies the validity of the Stocks-Einstein equation to ion diffusion in molten salts is limited by the systems, where the process of complex formation is absent, that is why the significant deviations from the equation take place in KCl – NaCl, and especially in the pure KCl,: D=KT/(6r), (1) where - viscosity, r – ion radius according to Goldschmidt. Using oscillographic method I.I. Naryshkin and V.P. Yurkovskyi determined lead, silver and cadmium ions diffusion coefficients depending on temperature against the equimolar mixtures NaCl-KCl and LiCl-KCl. Platinum microelectrode, the platinum wire butt with 0.6 mm diameter, soldered into a quartz capillary was used. 400 mm2 platinum foil was used as anode. Chloride-silver electrode was used as the reference electrode. Short circuit during two minutes was used to renovate the electrode surfaces after each observation. For obtaining the more reliable results each curve was observed several times and the results were averaged out. Authors showed the direct dependence of the peak current from the investigated ions concentration. This fact confirms the conclusion of Hills, Ocsley and Terner [11] about the possibility of the oscilligraphic voltamperometry for the rapid quantitative analysis in the molten salts. Dependence of the peak potential from the logarithm of investigated ion concentration for cadmium, lead and silver was found. Independence of the peak potential from the concentration logarithm for cadmium and lead chlorides corresponds to the dissolved matter deposition. Linear dependence observed for the silver chloride demonstrates the absence of solubility in the process of silver deposition. The following valence values were found: for silver 1.16, for lead 2.4. In the works [7-9] diffusion coefficients of lead, zinc and cadmium ions in the LiCl – KCl и NaCl – KCl melts were determined. Raymond J. Heus and James J.Egan [7] used polyrophic method to study processes of lead, zinc, cadmium ions electroreduction in the molten chlorides. Dropping bismuth electrode was a cathode. Silver chloride, containing 2 mass. % of AgCl in KCl – LiCl (eutectics) was a reference electrode. Authors obtained linear dependencies of the concentration of 187 the investigated chlorides from the diffusion current densities. Diffusion coefficients were calculated with the Ilkovich equation. Richard B. Stein [8] investigated the ion reduction reaction of divalent lead in the NaCl – KCl melt with oscillographic polyrography method. Platinum microelectrode, with 0.5 mm diameter, soldered into the quartz tube with 1,89х10-3 cm2 square, was a cathode. Reference electrode was silver chloride and the auxiliary electrode was graphite. Author founded out that the lead ion diffusion coefficients obtained by the experimental data differ from calculated according to the equation of Stocks-Einstein. He derived the conclusion that the cation structure is more complex than just a single ion. H.A. Laitinen, H.C.Gaur [9] investigated lead, cobalt and thallium ion reduction in the molten potassium and lithium chlorides with chronopotenciometry method. Authors fixed the value of the transition time for melts, containing the control values of ions under investigation. According to the experimental data empiric dependences of concentrations and transitional time were determined. Coefficients of cadmium, cobalt lead and thallium ion diffusion were calculated with Sand’s equation (2,08; 2,42; 2,18; 3,88*10-5 cm2/s correspondingly). Cathode processes in chloride melts containing lead ions were studied by chronopotentiometric and stationary galvanostatic polarization curves methods. Experiments were carried out in the cell made of quartz hermetically closed fluoroplastic cover (2) with the holes for electrodes and thermocouple with accordance to the Fig.1 Glassy-carbon was a working electrode (cathode). Glassy-carbon container played a role of a counter electrode. Melted equimolar mixture of lead, lithium and potassium chlorides was used as the electrolyte for the reference and working electrodes. Electrolytes of the working electrode and reference electrode were separated by the diaphragm from the Gooch asbestos (7). Measurements were conducted relatively to the lead reference electrode that is a metal lead of C1 grade being in contact with the melt containing 5 mass. % of lead chloride. Potassium chloride, lithium chloride chemically pure grade and lead chloride of pure for analysis grade were used for electrolyte preparation. Glassy-carbon container (4) was placed on the cell bottom on the special fireproof brick support (8). 188 Current lead to liquid-metal reference electrode was realized in a form of molybdenum rod and to glassy-carbon crucible through graphite bar. Current leads were protected from the contact with melt by alundum tubes closed with the rubber plugs (1) to keep the cell hermetically closed. 1 Ar 2 Vacuum 9 3 4 5 10 6 7 11 8 Fig. 1. Electrolytic cell. 1 – rubber plugs; 2 – fluoroplastic cover; 3 – thermocouple; 4 – glassy-carbon container; 5 – quartz-glass sell; 6 – working electrode; 7 – diaphragm; 8 – fireproof brick support; 9 – current leads to electrodes; 10 – electrolyte; 11 – reference electrode. 189 The cell was pumped out and fullfilled with purified argon. Later it was put into the resistance furnace and heated until the given temperature under the abundant pressure of the inert gas. The setup was equipped with the automatic system of temperature stabilization. Temperature measurement was performed with the help of chromyl-aluminum thermocouple. Content of components in electrolyte were being controlled before and after the experiment with the atomicabsorption method. Stationary polarization measurements Lead ion deposition processes in eutectic melt of lithium and potassium chlorides were studied at 0.4 to 3.0 mol. % lead chloride in temperature range from 673 to 823 К. Polarization curves are given on the fig. 2 and 3. Two characteristic areas are observed on the polarization curves. On the first area little potential deviations from the equilibrium value takes place with cathode current density increasing to 0.08 A/cm2. Experimental points on the area with 0.4 mol % lead chloride concentration are on straight lines described by equations: E = - 0,0703lgi - 0,1203 and E = - 0,0775lgi - 0,091 for 673 and 773 К correspondingly. At temperature 673 К tg is 0,070 мВ, and at 773 К - 0,078 мВ. According to the equation: n 2,3 RT tgF (2) we have n=1,9 for 673 К and n=2,0 for 773 К. At lead chloride concentration 3,0 mol % experimental points on the first area of the polarization curve is described by the equation E= - 0,0779lgi - 0,0877. Amount of electrons in the reaction calculated on the equation (2) is equal 2. Reaching current densities 0,11; 0,12; 0,20 и 0,32 А/сm2 on the fig.3 for 673, 723, 773, 823 К temperatures correspondingly. Potential is greatly shifted to the negative area to the values -0,84; -0,84; -1,06 and -1,10 correspondingly. At small values of cathode current density there is one wave correspondingly to the fig. 4. In some time after current rise potential 190 reaches its stationary value at current density 0,045 А/сm2 for 3,5 s, for current density 0,060 А/сm2 for 3,0 s. After current disconnection, potential comes back to its equilibrium value. Fig. 2. Polarization curves of lead ions (II) deposition in LiCl – KCl – PbCl2 (0.4 mol. %) melt. 191 Fig. 3. Polarization curves of lead ions (II) deposition in LiCl – KCl – PbCl2 melt at 823 К depending on the lead chloride concentration. Concentration of lead chloride in mol per cents: 1 - 0.4; 2 - 0.5; 3 – 3.0. 192 Fig. 4. Engaging curves at 823 К temperature and the different current density. On the engaging curves at current density values corresponding to the second characteristic area on the polarization curves on the figures 2 and 3 two waves on figure 5 are seen. Time of reaching stationary potential tst decreases with the current density increasing (for current density 0,12 А/сm2 tst equals 8,5 s, for current density 0,17 А/сm2 tst 4,5 s). Fig. 5. Engaging curves at 0.4 mol. % lead chloride concentration, current density 0.12; 0.13; 0.17 А/сm2 and 823 К. 193 Processes taking places on the electrode can be described in the following way. On the first characteristic area of the polarization curve lead ion deposition happens: Pb2+ + 2e = Pb0 (3) The limiting current density of lead reduction increases with the temperature and lead chloride concentration. At 3.0 mol. % of lead chloride concentration and 823 K limiting current density i lim is 1.2 A/cm2. On the second characteristic area of the polarization curve deposition of the alkaline metal is possible on the reaction: K+ + e = K0 (Pb) (4) Low values of the alkaline metal reduction potentials might be connected with the process of alloy formation of alkali metal with lead K + 4Pb = KPb4 (5) Chronopotentiometric measurements at lead deposition from LiCl – KCl (45-55 mol. %) – PbCl2 melt at 0.4 mol. % lead chloride concentration were performed at 823 K and current density range from 0.10 to 0.17 A/cm2. There is only one wave on chronopotentiometric curves under these conditions. Values of product i1/2 depending on current density are given in the table 1, where - transition time. Table 1. Values of product i1/2 at diverse current density , s i, mA/cm2 i1/2, mA/cm2s1/2 0,95 170 165 1,61 130 165 1,81 120 162 2,62 102 165 It is seen that the product i1/2 does not depend on current 0 density at constant concentration of depolarizator C Ox . In the table 2 potential values Е/4 at time equaling the forth of the corresponding values of transition time are given. 194 Table 2.Values of Е/4 potential of different current density i, A/cm2 0,10 0,12 0,13 0,17 , s 2,64 1,81 1,61 0,95 /4, s 0,660 0,453 0,403 0,238 Е/4, V -0,061 -0,600 -0,061 -0,062 It is seen that the potential Е/4 does not depend on the experiment conditions, the current density in this case. Equation for the reversible process can be as follows: Е Е / 4 1/ 2 RT ln 1 , nF t (6) for irreversible process: 1/ 2 0 0 RT nFCOx k fh RT t Е ln ln 1 , nF i nF (7) where E – electrode potential, E / 4 - measurement potential at ¼ of transition time, R – gas constant, F – Faraday number, n – number 0 of electrons, T – temperature, - transition time, C Ox - depolarizator concentration, k 0fh - deposition speed constant. On the figure 6 dependencies Е - ln t t ln 1 1/ 2 at 0.4 mol. % of 1/ 2 1 and Е lead chloride concentration, current density 0.1 A/cm2 and 823 K are given. 195 - E, В 0,162 0,142 0,122 0,102 y = -0,0835x + 0,0654 0,082 0,062 0,042 0,022 -1,15 -0,65 -0,15 0,35 1 Fig. 6. Dependencies 1–Е=f ln t 0,002 0,85 2 1/ 2 1 and 2-Е =f t ln 1 1/ 2 . From the analysis of given graphic dependencies follows that the 1/ 2 experimental points in coordinates E - ln 1 are in a straight line t with the confidence interval 0.95. The can be described by equation: E 0,065 0,083 ln t 1/ 2 1 (8) The amount of electrons in the electrode reaction was calculated from the equation: n RT , 0,083F (9) hence n=2. 196 It follows from the experimental conditions on lead ion (II) deposition that the process is reversible, i.e. it is controlled by the speed of divalent lead ions mass transfer from the volume of melt to the electrode surface. Diffusion coefficient of lead dichloride at 823 K was calculated on Sand’s equation: 2(i ) 2 D (nFCox0 ) 2 (10) Lead ions (II) diffusion coefficient are equal to 2,33·10сm /s. It is in good accordance with the data obtained by other authors [5, 6]. 5 2 References 1. Yurkinsky V., Makarov D. Electrochemical reduction of lead ions in halide melts. Russian J. Applied Chem., 1994, 67, p. 1283-1286. 2. Yurkinsky V., Makarov D. The influence of cation composition on kinetics of lead electrochemical reduction in chloride melts. Russian J. Applied Chem., 1994, 68, p. 1474-1477. 3. Ryabukhin Yu. And Ukshe E. The diffusion coefficients of lead in molten chlorides. DAN SSSR, 1962, 145, p. 366-368. 4. Naryshkin I., Yurkinsky V. Oscillographic investigation of temperature coefficients for some chlorides diffusion in LiCl-KCl. Russian J. Electrochemistry, 1968, 4, p. 871-872. 5. Naryshkin I., Yurkinsky V. Voltammetry in molten salts. Russian J. Electrochemistry, 1968, 2, p. 856-866. 6. Raymond J. Heus, James J. Egan. Fused Salt Polarography Using a Dropping Bismuth Cathode. – J. of the Electrochemical Society, October 1960, p. 824-828. 7. Richard B. Stein. The Diffusion Coefficient of Lead ion in Fused Sodium Chloride Eutectic. – J. Electrochem. Soc., 1959, vol. 106, p. 528. 8. Laitinen H. A., Gaur H. C. Chronopotentiometry in Fused Lithium Chloride-potassium Chloride. - Anal. Chem. Acta, 1958, vol. 18, p. 1-13. 9. Hills G.I., Oxley I. E., Turner D. W., Silicates Ind., 1961, vol. 26, p. 559. 197