Material Handling - Department of Mechanical and Automation

advertisement

Chapter 5: Material Handling

5.1 Introduction

- Historically, material handling is to move the materials around. Since manufacturing is a

value-added operation and move materials around does not add any value, the simple rule

for material handling is the less (cost, time, labor and etc.) the better.

- Today, it is recognized that material handling is an integrated part of any manufacturing

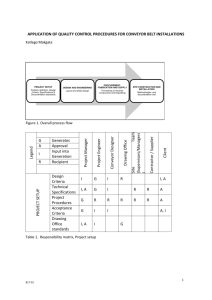

system as shown in the figure below.

Tooling

design and

analysis

Machine

tool and

control

Material

handling

Design

analysis

customer

Design

Manufacturing

Bill of

materials

Process

planning

Usage and

disposal

customer

Quality

control

Fig. 1: Material handling and manufacturing systems

-

-

-

In most manufacturing plants, materials spend more time being moved and stored than

being processed (it could be as much as 90% of the time). Therefore, analysis and design

of material handling system is very important.

This chapter corresponds to Chapter 7 in the textbook and Chapters 9 and 10 in Reference

[3]. It is interesting to know that there is a course in the Dept. of Systems Engineering and

Engineering Management that discuss only the material handling.

Material handling involves a rather broad body of knowledge. However, we will focus on

only some fundamental issues including basic principles, various material handling

equipment such as conveyor and AGV (Automated Guided Vehicle), material route

planning, and Automatic Storage and Retrieval Systems (AS/RS).

5.2 Basic Concepts and Principles of Material Handling

(1) Some important concepts

- A material system is an integrated system involving such activities as handling, storing,

and controlling of materials

- In material handling, material has a rather broad meaning, covering all kinds of raw

materials, work in progress, sub-assemblies, assemblies, and finished assemblies

- The primary objective of using a material handling system is to ensure that the material in

the right amount is safely delivered to the desired destination at the right time with

minimum cost.

5-1

(2) The Principles of material handling

- The handling of materials must be performed safely, efficiently (at low cost), in a timely

manner, accurately (the right materials in the right location), and without damage to the

material.

- The Material Handling Institute has complied 20 basic guidelines for designing and

operation material handling systems. These guidelines are referred to as the principles of

material handling. These principles are listed below.

- Orientation principle. Study the system relationships thoroughly prior to preliminary

planning in order to identify existing methods and problems, physical and economic

constraints, and to establish future requirements and goals

- Planning principle. Establish a plan to include basic requirements, desirable options,

and consideration of contingencies for all material-handling and storage activities.

- Systems principle. Integrate the handling and storage activities that are economically

viable into a coordinated system of operation including receiving, inspection, storage,

production, assembly, packing, warehousing, shipping and transportation.

- Unit load principle. Handle product in as large a unit load as practical.

- Space utilization principle. Make effective utilization of all cubic space.

- Standardization principle. Standardize handling methods and equipment whenever

possible.

- Ergonomic principle. Recognize human capabilities and limitations by designing

material handling equipment and procedures for effective interaction with the people

using the system.

- Energy principle. Include energy consumption of the material handling systems and

material handling procedures when making comparisons or preparing economic

justifications.

- Ecology principle. Minimize adverse effects on the environment when selecting

material handling equipment and procedures.

- Mechanization principle. Mechanize the handling process where feasible to increase

efficiency and economy in handling of materials.

- Flexibility principle. Use methods and equipment that can perform a variety of tasks

under a variety of operating conditions.

- Simplification principle. Simplify handling by eliminating, reducing, or combining

unnecessary movements and/or equipment.

- Gravity principle. Utilize gravity to move material whenever possible, while

respecting limitations concerning safety, product damage, and loss.

- Safety principle. Provide safe material-handling equipment and methods that follow

existing safety codes and regulations in addition to accrued experience.

- Computerization principle. Consider computerization in material handling and storage

systems, when circumstances warrant, for improved material and information control.

- System flow principle. Integrate data flow with the physical material flow in handling

and storage.

- Layout flow principle. Prepare an operational sequence and equipment layout for all

viable system solutions, then select the alternative system that best integrates

efficiency and effectiveness.

- Cost principle. Compare the economic justification of alternative solutions in

equipment and methods on the basis of economic effectiveness as measured by

expense per unit handled.

- Maintenance principle. Prepare a plan for preventive maintenance and scheduled

repairs on all material-handling equipment.

5-2

-

Obsolescence principle. Prepare a long-range and economically sound policy for

replacement of obsolete equipment and methods with special consideration of aftertax cycle costs.

- To begin with, we usually use an existing design.

- Considering the situation in Hong Kong, we probably should pay special attention to

planning principle, the simplification principle, and the cost principle.

(3) Material handling equipment

- There are many different kinds of material handling equipment. These equipment can be

classified into the following categories:

- Conveyors such as belt, trolley, and feeders (screw, vibrating and pneumatic),

- Monorails and cranes (bridge, gantry, tower, and stacker)

- Industrial trucks and forklifts, both hand-lift and powered,

- AGVs such as carrier, pallet trucks and fork trucks

- Automated storage and retrieval systems

- The choice to these equipment depends on a number of factors such as the amount of

materials to move, the type of materials, the cost and etc. As shown in Figure 2, conveyor

and fork truck are two types of material handling equipment. The former provides

maximum capacity but no flexibility. On the other hand, the later provide limited

capability but very good flexibility.

Conveyor

Monorail

Crane

AGV

Fork truck

Continuous production

Single parts production

High volume production

Discrete production

Limited batches

Low volume production

A large number of batches

Fig. 2: The spectrum of material handling equipment

(4) The analysis or design of a material handling system begins with capacity planning, by

which we can determine what kind of material handling equipment will be used.

5.3 Selection of Material Handling Equipment

(1) The selection of material handling equipment starts with an analysis of the materials to be

moved. The analysis includes

- The characteristics of the material. In general, materials can be classified as follows:

- physical forms: solid, liquid, gas

- size:

- length, width, and height

- volume

- weight:

- weight per piece,

- weight per unit volume

- shape: long and flat, round, square

- risk of damage: fragile, brittle, sturdy

5-3

- safety risk: explosive, toxic, corrosive

- condition: hot, wet, dirty, sticky

- Other factors

- The quality of material to be removed (a dedicated system will be needed for large

quality)

- The rate of flow required (a dedicated system will be required for high rate of flow)

- The scheduling of the moves (continuous, in batch, or one at a time)

- The route by which the materials are to be moved (the longer the distance, the greater

the cost)

- Miscellaneous factors:

- government regulations

- loading and unloading equipment

- ……

(2) Material handling analysis

- Manufacturing facilities may be layout in many different ways. There is a topic of study,

called facility layout. However, we will not be able to study its details.

- In general, a layout should provide the following information:

- Locations where materials must be picked out (loading stations)

- Locations where materials must be delivered (unloading stations)

- Possible routes between these locations

- Distances that must be traveled to move the materials

- Flow patterns, opportunities to combine deliveries, possible places where congestion

might occur

- Total area of the facility and areas within specific departments in the layout

- Arrangement of equipment in the layout.

(3) Material handling equipment selection model

- The basic mathematical model for material handling equipment selection is a

mathematical programming model.

- Assuming that

- M equipment types are available,

- N product moves are to be planned.

- The unit load size is known for each part type

- A factory layout is know.

- Hence, the frequency and distance required for each move, j, j = 1, …, N is known.

- The decision variables are:

1 if equipment type i is used for move j

X ij

otherwise

0

Yi = number of units of equipment type i acquired.

- The cost factors:

- cij = total variable operating cost per period for equipment type i to perform move j

- Ci = fixed cost per unit-period for equipment type i

- tij = time per move for equipment i to perform move j

- Ti = available time per unit-period for equipment type i

- The model:

M N

N

i 1 j 1

i 1

min cost/perio d cij X ij CiYi

subject to:

5-4

M

X ij 1 , for all j

i 1

N

tij X ij TiYi , for all I

j 1

Xij = {0, 1} and Yi is integer

-

This is model is an integer programming model.

An example

- Three alternatives (pushcart, power truck, and conveyor) are being considered for six

inter-department moves.

- The move data and cost are as follows:

1

Move

1

2

3

4

5

6

Ci

-

-

t1j

0.72

1.50

0.15

0.21

0.15

0.36

3

t2j

0.24

0.50

0.12

0.07

0.05

0.12

c3j

890.0

3600.0

325.0

1200.0

1050.0

9999.0

0

t3j

1.0

1.0

1.0

1.0

1.0

1.0

Note that since the conveyor are fixed, its time is fixed 1 indicating. However, it

cannot be used for more than one point-to-point move. So, for move 6, the cost is set

to very large.

Using the data above, the optimization model becomes:

min

s.t.

-

c1j

1286.4

2680.0

268.0

375.2

268.0

634.2

75.0

Equipment type

2

c2j

640.0

1333.3

320.0

186.7

133.3

320.0

389.5

1286.4X11 + 2680.0X12 + … + 9999.0X36 + 75.0Y1 + 389.5Y2

X11 + X21 + X31 = 1

…

X61 + X62 + X63 = 1

0.72X11 + 1.5X12 + 0.15X13 + 0.21X14 + 0.15X15 + 0.36X16 Y1

0.24X21 + 0.50X22 + 0.12X23 + 0.07X24 + 0.05X25 + 0.12X26 Y2

Solving this optimization problem resulting in:

x21 = x22 = x24 = x25 = x26 = x33 = 1, Y2 = 1.

with all other variables equal to zero. This indicates that we shall purchase a conveyor for

move 3 and lift trucks for the rest moves. The total cost is 3327.83.

(4) A modified model

- The model presented above is an integer programming model, which is difficult to solve

(MATLAB does not support that). Therefore, the following modification is introduced.

- The modification is to allow the model solution, Yi, to take fractions (which means the

number of equipment purchased will have to round up to nears integer).

- Let:

5-5

N

tij X ij

Yi

-

j 1

Ti

the model becomes:

M N

minimize

cij' X ij

i 1 j 1

-

-

where, c’ij = cij + (tij / Ti). The constraints are the same.

The modified model can be solved using mathematical programming method (and

MATLAB). However, it would result in a loss. In order words, the solution may not be

optimal, instead it would be just sub-optimal.

In the example before, the data would become:

Move

1

2

3

4

5

6

-

-

c1j

1340.4

2792.5

279.3

391.0

279.3

670.2

c2j

733.5

1528.1

366.7

213.9

152.8

366.7

c3j

890.0

3600.0

325.0

1200.0

1050.0

9999.0

Note that since T3 = 0, we just set c’ij = cij.

Solving the program (the lower bound), it is found:

x13 = x21 = x22 = x24 = x25 = x26 = 1, Y1 = Y2 = 1.

and the cost is $3274.3.

This implies we should use a fork truck for moves 1, 2, 4, 5 and 6, and a manual cart for

move 3.

Note that the cost is higher, and hence, the solution is sub-optimal.

5.4 Material Handling Equipment – Conveyor

(1) In terms of operation, conveyors have the following characteristics:

- They are generally mechanized, and sometimes automated

- They are fixed-in-position to establish the paths

- They can either floor mounted or overhead

- They are almost always limited to one-directional flow materials

- They are generally move discrete loads, but certain types can be used to move bulk or

continuous loads

- They can be used for either delivery-only or delivery-plus-storage of items

(2) There are several types of conveyors, such as

- Roller conveyors

- Belt conveyors

- Chain conveyors

- Slat conveyors

- Overhead trolley conveyors

- In-floor towline conveyors

- Cart-on-track conveyors

(3) The main quantitative measure of a conveyor system includes

- Velocity, Vc, (ft / min or m / min)

5-6

(4)

-

Rate of flow of parts, Rf, (parts / h)

The efficiency of the system, Eh

Single direction conveyor

A single direction conveyor is shown in Figure 3. Its typical operation is to load carriers

or pallets at one end and unloaded at the other end.

Ld

Vc

Load

station

Conveyor path

Unload

station

Fig. 3: Single-direction conveyor

-

The time required to move the carrier from the load station to the unload station is:

T l = L d / Vc .

- The carrier flow rate cannot be greater than the reciprocal of the loading time, that is:

Vc

1

S c TL

where, Sc is the spacing between the carriers.

- The time required to unload the carrier, Tu, must be less than or equal to the loading time;

or the conveyor must be slow down

- If each carrier holds np parts, the flow rate of the parts will be:

n pVc n p

Rf

Sc

Tl

- The single-direction conveyor has a relatively high efficiency since there will be no

traffic congestion along the conveyor, and conveyor does not stop for loading and

unloading.

- However, it also has the least flexibility.

(5) Continuous loop conveyor

- Comparing to the single-direction conveyor, the continuous loop conveyor has a return

loop as shown in Figure 4.

Return loop

Vc

Load

station

Delivery loop

Fig. 4: Continuous loop conveyor

5-7

Unload

station

-

Assuming that

- The spacing between the carriers is Sc

- Each carrier holds np parts

- The length of delivery loop is Ld

- The length of return loop is Le

- Then, it follows that

- The (maximum) number of carriers in the system will be:

L Le

nc d

Sc

- The total number of parts in the system

n p Ld n p nc Ld

TP

Sc

Ld Lc

- The flow rate of the system:

n pVc

Rf

Sc

(6) Recirculating conveyor

- In the previous model, it is assumed that the parts are continuously moving and no

accumulation of parts is permitted. In practice, it is possible to add a buffer to the

conveyor system to maintain a smoother material flow. Such a system is called the

recirculating conveyor.

- The problems in operating a recirculating conveyor system are:

- No empty carriers may be immediately available at the loading station when needed

- No loaded carriers may be immediately available at the unloading station when

needed

- The principles to operate recirculating conveyor systems are as follows:

- Speed rule. The speed at which the conveyor is operated must be within a certain

permissible range; the lower limit is the loading / unloading rate and the upper limit is

speed limit of the conveyor.

- Capacity constraint. The capacity of the conveyor system must be at least equal to the

flow rate requirement.

- Uniformity principle. The parts should be uniformly loaded throughout the conveyor.

5.5 Material Handling Equipment – Automated Guided Vehicle

(1) AGV is a material handling system that uses independently operated, self-propelled

vehicle that are guided along defined pathways in the floor. Owing to its

programmability, it is very effective in modern manufacturing.

(2) There are number of different types of AGVs including:

- Driverless trains

- AGV pallet trucks

- AGV unit load carriers

- AGVs involve the use of several hi-tech technologies such as computer network, remote

sensing, automatic vehicle guidance and routing. However, we will discuss it from the

application point of view. Our focus is capacity planning.

(3) Capacity planning

- Figure 5 shows a typical shop floor layout consisting of five workstations and a loading

duck. The question is to determine how many AGVs are needed for material handling.

5-8

-

-

There are several ways to determine the capacity and one of them is the from-to chart. A

from-to chart is like a mileage chart on a road map. It describes either the number of

deliveries required or distance between different stations.

For the example in Figure 5, the from-to charts are shown in Tables 1 and 2.

Station 1

Station 4

Station 2

Station 5

Station 3

Loading duck

Fig. 5: an example of workstation layout

Table 1: From-to chart showing the flow rate (number of deliveries required in unit time)

between different stations

To

From

1

2

3

4

5

1

0

9

5

6

0

2

0

0

0

0

9

3

0

0

0

2

3

4

0

0

0

0

8

5

0

0

0

0

0

Table 2: From-to chart showing the distances between different stations (NA indicates that

the distances are not applicable to this layout)

To

From

1

2

3

4

5

1

0

200

400

700

NA

2

NA

0

NA

NA

300

3

NA

NA

0

300

600

4

NA

NA

NA

0

300

5

100

NA

NA

NA

0

-

-

Based on the from-to chart, we can find the so-called transport work, TW:

TW = RfLd

where, Rf represents the flow rate (piece / hour) and Ld represents the length of delivery

Aggregate the transport work for all the deliveries, we obtain the total transport work,

TTW:

TW = RfLd

5-9

-

For example above, the TWs are shown in a flow diagram as shown in Figure 3 and the

TTW is:

TTW = 9*200 + 5*400 + 6*7000 + 2*300 + 9*300 + 3*600 + 8*300 = 15,500

6

1

4

5

8

9

9

2

5

2

3

3

Fig. 6: the flow diagram corresponding to the example: nodes represent loading and

unloading workstations and arrows with number represent indicate the material flow rate

-

-

-

In practice, the actual TTW is usually higher because of the losses during the operations.

In fact, the total amount of time for material handling include:

- The time of the delivery: (Ld / Vc), where, Ld is the distance between the origination to

the destination, and Vc is the speed of the material handling system.

- The time of loading and unloading, Th.

- The time of empty travel, (Le / Vc), where, Le is the distance of the empty move.

- The time traffic factor, Eh.

Hence, we can define an efficiency measure:

Ld Vc

Eh

Ft

Ld Vc Le Vc Th

The required handling system capability is:

TTW

Cm

Eh

When there are np parts are needed to handle, the required handling system capability is:

TTW

Cm

n p Eh

-

-

Note that in the above study, the workstation layout and the material delivery paths are

fixed. To design a better workstation layout and / or a material delivery path, we must use

the group techniques described in Chapter 6.

The textbook presents another formal, which will be discussed in the tutorial.

5.6 Automated Storage and Retrieve Systems

(1) Although many manufacturing companies are driving for the so-called Just-In-Time (JIT)

manufacturing (which will be discussed in Chapter 7), it is inevitable that the materials

have to be stocked or stored for use. Therefore, there are warehouses, and automated

storage and retrieve systems (AS/RS) in various level.

5-10

(2) In a warehouse, many activities may occur as shown below:

Table 3: Warehouse facilities and activities

Facilities

Activities

Storage racks / slots

Storage

Quality control

Receiving inspection

Receiving docks

Unloading, depacking, identifying, sorting

Store / retrieve

Location selection, transport, S/R request sequencing

Manufacturing

Parts preparation (for shop floor release)

Shipping docks

Order assembly, packing labeling, loading

(3) Warehouses big or small may be arranged in various forms. However, it has five basic

components including building shell, storage medium, transport mechanism, and controls

/ polices. Let discuss these components in more details.

- Building shell. It supplies space and a controlled environment for product, equipment, and

personal. The shell should be lightweight (for saving building materials and for easy of

rearrange when necessary), and strong enough to hold the intended storage items.

- Storage medium. Storage racks are used to hold loads. A typical example is pallet racks.

Its standard size is 24 x 32 inches to 48 x 48 inches. Pallet racks can be placed back to

back, and/or stacked one on the other allowing large storage space.

- Transport mechanisms. They may be either automated, semi-automated, or manual, and

are used to transport loads from place to place. The most commonly used machine is the

forklift type machine. Note that manual transport mechanics require larger spaces.

- Control / police. The basic policy decision is whether to have dedicated or open storage.

In dedicated storage, each product has its own permanent storage areas. Open storage, on

the other hand, allows loads to be placed in any location.

(4) Warehouse design

- The basic principle for warehouse design – the 85% rule:

- use 85% of the slots

- use 85% of the cubes is each slot.

- The size of the warehouse. Figure 7 shows a typical warehouse setup, where a is the

number of storage rows and b is the number of storage columns, a is and b are size of the

storage rows and columns respectively including the aisle spaces.

Loading /

unloading

dock

b

a

Fig. 7: Illustration of a typical warehouse dimension

5-11

-

-

-

Suppose the warehouse has n levels and a total of K locations are needed for storage

(remember the 85% rule), then we must have abn K.

If all the locations are used equally, the average trip has a one-way distance of

[a/2 + b/4]

The longest trip is:

[a + b/2]

Therefor, to minimize the warehouse shape , you will have:

a b

minimize

2

4

K

a b

subject to:

n

a, b integer

Suppose a and b are sufficiently large, then we can relax the integer condition. Substitute:

a = K / bn

to the objective function, take differentiation and set to zero, it follows that:

K

0

2nb 2 4

Therefore, the solution is:

1

-

1

2K 2

K 2

, a*

b*

2n

n

An example: all the loads are on 36 x 36 inches pallets, bays are 42 x 42 inches (85%

rule), the warehouse has one layer (n = 1), and the space factors are = 2, = 1; find the

number of columns and number of rows necessary.

K = 42 x 42 = 1764

1764

a*

2*2*4

1

2

10.5 11

1

2 * 2 *1764 2

b*

59.3 60

1* 2

In addition, the average one-way distance is:

a b

11 15 26 (locations)

2

4

(5) Location assignment – dedicated storage

- Suppose there are N parts to be allocated to storage locations in a warehouse, each has its

dedicated location. The dedicated storage allows us to find a part easily (however, it may

be very efficient).

- The storage space necessary:

n

S bath size safety stock

i 1

-

The objective of allocation of the space is to minimize the average assessment time

The algorithm is rather complicated and hence will not be covered. However, we will

discuss a simple case, whose solution is rather straightforward.

Assumption:

- warehouse is divided into M equal capacity grids

- Product i, i = 1, 2, …, N requires a maximum of Ai grid squares for storage

5-12

N

-

A

i 1

-

-

-

i

M (we can always add a dummy product to fill the space)

there are two ports in the warehouse, one for receiving and one for shipping

the product trip / period is:

wip = ci wp

where, ci is the total volume of product i moving in and out of storage per time period,

wp is the proportion of loads that use port p.

the cost per period for Product i in grid j is:

c P

cij i w p d pj

Ai p1

where, dpj is the distance between Port p to Grid j.

let

P

f j w p d pj

p 1

-

-

-

the total objective function becomes

N M

c

minimize i f j

i 1 j 1 Ai

- note that the each fj is matched a ci / Ai, In other words, the objective function will be

minimized by matching small values in fj with large values in (ci / Ai).

Solution: from a physical point of view, this indicates that the areas closer to the ports

should be used to store the product with large quantities.

The algorithm:

Step 1:

order grids: computer fj, j = 1, 2, …, M, place the grids in nondecreasing order

of fj, that is, f[1] f[2] … f[M]

Step 2:

order product: put products in nonincreasing order, that is,

c[1] c[ 2 ]

c[ N ]

...

A[1] A[ 2]

A[ N ]

Step 3:

assign products: for i = 1, 2, …, N assign product [i] to the first A[I] grid

squares still available.

An example: consider a warehouse setup as shown in Figure 8, in which the loads are

received at (0, 0) and shipped at (5, 0). Three products are stored and all products make

four times as many trips to the shipping as from the receiving. Storage and throughput

requirements are given below. Assign products to storage locations.

8.2

7.6

7.0

6.4

5.8

V

V

1

1

1

7.2

6.6

6.0

5.4

4.8

1

1

1

1

3

6.2

5.6

5.0

4.4

3.8

1

1

3

3

3

5.2

4.6

4.0

3.4

2.8

1

3

3

2

2

4.2

3.6

3.0

2.4

1.8

3

3

2

2

2

(0,0)

Product

fj values

(5,0)

(0,0)

No. of grids required

5-13

Optimal assignment

(5,0)

Total loads moved per day

1

2

3

10

5

8

100

150

160

-

The solution is as follows:

Step 1:

compute fj form fj = 0.2d1j + 0.8d2j, the result is shown in the table above.

Step 2:

order the product according to (ci / Ai), it is easy to find:

[(c1 / A1), (c2 / A2), (c3 / A3)] = [10, 30, 20],

in other words, Product 2 is most important followed by Product 3 and then 1.

Step 3:

assign Product 2 to the best A2 = 5 position, followed by Product 3 and 1. The

unassigned position is marked as “V” (vacancy). The final result is shown in

the table above.

(6) Location assignment – open storage

- The location assignment in open storage (also called random storage) is made possible by

the use of computers

- The space requirement calculation is the same as that of the dedicated storage

- Since the parts would be randomly stored, there is no need for the location assignment.

- We can calculate the expected stocking / retrieving time by averaging.

(7) Picking up the orders

- Suppose we want to pick up an order consisting of just 1 product, all we have to do is to

allocate the storage position and go there to pick it up.

- However, suppose we want to pick up an order consisting of n products stored in n

different places, then it is difficult to find the optimal solution. In fact, it is equivalent to

the travel salesman problem. It is called NP-incomplete problem and we cannot find the

optimal solution when n is large. But, as you can image, a simple sub-optimal solution

will do the job just fine.

- One of the simple methods for sub-optimal solution is the minimum distance algorithm as

demonstrated below. Suppose there are n locations, and each location is marked by its

coordinate Li(x, y, z), i = 1, 2, …, n, and the pickup list is marked by:

99999 if no product wi ll picked up from location i

ai

otherwise

1

Step 1: start from the initial workstation (the loading / unloading dock), set it as the current

position, c(x, y, z).

Step 2: calculate the distances between the current position to all the locations;

Di = || c(x, y, z) – Li(x, y, z) ||ai, i = 1, 2, …, n.

Step 3: add the location whose distance is the minimum to the to go list

Step 4: set the selected location as the current position, repeat Step 2 until all the locations are

searched.

- This algorithm is simple, and you may try a simple example by yourself.

(8) Automated Storage / Retrieval Systems (AS/RS)

- AS/RS is a basic component in warehouse and modern manufacturing systems.

- In manufacturing systems, in addition to store and retrieve materials, AS/RS also carry on

transportation tasks sending the parts to specific areas.

- There are several types of AS/RS

- Unit load AS/RS: used to store and retrieve large or palletized loads in standard size

containers and it is usually automatic (Figure 7.7 in the textbook)

- Miniload AS/RS: used to small loads such as tools and supplies

5-14

-

-

Person on-board AS/RS: a person rides with the S/R machines

Deep lane AS/RS: a variation of unit load system for high density storage and

retrieval and it usually has many racks in one lane

The design of an AR/RS. In order to design a AR/RS system, following factors shall be

considered

- The load sizes

- The dimensions of an individual storage space

- The number of storage spaces, note that:

- The 85% rule

- It would be different for dedicated storage and random storage

- The system throughput and the number of AS/RS machines

- The size parameters of the space

- The number of rows, columns, layers, aisle, …

- The bay width, rack length, …

- Cycle time

- Utilization of S/R machines

These factors can be quantitatively measured using simple calculations as shown in the

examples in the textbook, which will be covered in the tutorial.

5-15