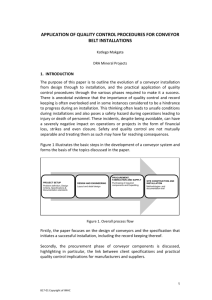

APPLICATION OF QUALITY CONTROL PROCEDURES FOR

advertisement

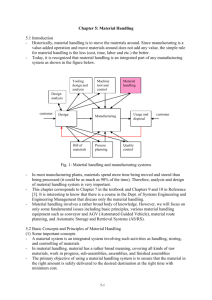

APPLICATION OF QUALITY CONTROL PROCEDURES FOR CONVEYOR BELT INSTALLATIONS Katlego Makgata PROJECT SETUP Problem definition, Design Criteria, Specifications & Documentation standards PROCUREMENT, FABRICATION AND SUPPLY Purchasing of required components and Expediting DESIGN AND ENGINEERING Layout and detail design SITE CONSTRUCTION AND INSTALLATION Methodologies and documentation trail PROJECT SETUP Design Criteria Technical Specifications Project Procedures Acceptance Criteria Drawing Office standards I G I I, A G I G R R G I I I, A I R R Client Contractor / Supplier Team Site (Supervisors/Managers ) Drawing Office R Conveyor Designer I Generates Approval Input into Generation Recipient Project Engineer G A Project Manager Legend Figure 1. Overall process flow I, A R R A R R A A, I G Table 1. Responsibility matrix, Project setup B17-01 1 Preliminary Layout Final Design to Updated layout (if necessary) Design Update layout to Design Issue for Fabrication/Construction Detail design ENGINEERING AND DESIGN Conveyor Design Conveyor Equipment Schedules Layout Drawings General Arrangement Drawings Structural Design Fabrication and Construction Drawings Checking and Approvals Prior to Issue to Contractor(s) Shop Detailing and Checking of Generated Drawings G R, A Client Contractor / Supplier Site Team (Supervisors/Managers) Drawing Office Structural Engineer R Conveyor Designer I Generates Approval Input into Generation Recipient Project Engineer G A Project Manager Legend Figure 2. Design and engineering process flow R R, A G R I, R I, R G I, R, A I, R R G R G R I, R A G A A A Approval Only on Engineer’s request A R, A R R R I I, A, R R R R R G Table 2. Responsibility matrix, Engineering and design phase B17-01 2 PROCUREMENT, FABRICATION AND SUPPLY Tender compilation and issue Adjudication & Contract Placement Certified Drawings Quality Control Plans NonConformances Concessions Data Books Client Contractor / Supplier Site Team (Supervisors/Managers ) Drawing Office Structural Engineer Conveyor Designer R Project Engineer I Generates Approval Input into Generation Recipient Project Manager Legend G A I, A G R I, A I, A G R I, A G R I, A R I, R R I, A G R G G R R A R G G R I I R Table 3. Responsibility matrix, procurement, fabrication and supply phase Figure 3. Gantry being pre-assembled B17-01 3 Figure 4. Rectification of a defective gantry Figure 5. Theodolite in position B17-01 4 • SKF allows 25 mm over bearing centres of 2 900 mm • CEMA specification allows 1/32 inches over bearing centres, i.e. 0.8 mm • Anglo American specification allows 1 in 1 000, i.e. 2.9 mm Table 4. Pulley alignment tolerances for bearing centres of 2 900 mm Figure 6. Flatness of pulley structure plates measured using feeler gauges Figure 7. Drive installation in progress B17-01 5 Figure 8. Splicing - hot vulcanisation in progress B17-01 6 Construction QC Dossier - Index Discipline: Mechanical Package Number: Form Reference No. No Index 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 18.1 18.2 18.3 Handover Documents QCP Access Certificates Civil Survey Reports Mechanical Installation QC Check Sheets Welding Documentation and Certificates NDT Reports Test Certificates Coating Repairs and DFT Reports Site Engineering Queries Site Instructions Non-conformance Reports Concession Requests As-built Drawings and Weld Maps Phase 1 Punch List Phase 2 Punch List Phase 3 Punch List Construction Completion Certificates Platework Structural Mechanical Required (a) Table 5. Typical data pack index Quality Project Cost Time Figure 9. The Project Management Triangle B17-01 7