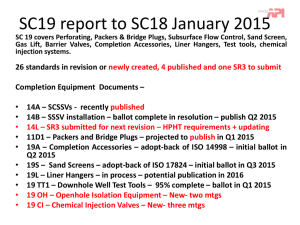

API RP 11V6, Recommended practice for design of continuous flow

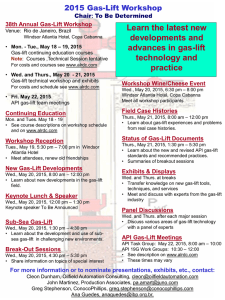

advertisement