Abstract

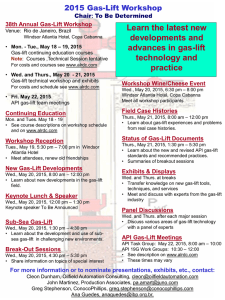

advertisement

Gas-Lift Optimization under Compression Capacity Constraints and Flaring Limits Vinicius Ramos Rosa Alex Furtado Teixeira Abstract Most of gas-lift papers that present optimization models have two common aspects. The first one is to optimize above a surface made by each well gas-lift performance curve. The second is to consider the total gas-lift rate to be shared among wells as a model input. These models work fine as long as the surface is smooth and there is no active compression system limits. Wells which have discontinuous gas-lift performance curves perform a not smooth optimization surface. Then, the surface optimization based on traditional gradient methods (like BFGS and Quadratic Programming) does not work. A commercial software was tried to optimize through operational boundary conditions but no reasonable solutions were obtained. Compression capacity should be a model input and total gas-lift rate a model variable in addition to wells gas-lift rates. This work describes two field-implemented methods based on Operational Research techniques, Dynamic Programming and Mixed Integer Programming, to overcome these modeling difficulties. The gas-lift optimization by Dynamic Programming model allows prescribing a set of wells which must be closed in case of compression system capacity constraint at a minimum well gas-lift rate. Optimization by Mixed Integer Programming performs a more complex model. It is possible to add operational constraints such as capacity reduction in produced water disposal system. It defines which wells can remain opened, their respective gas-lift rates and well head pressures. This model applies piecewise linearization to deal with non smooth surfaces. These models accomplish the optimization task at one offshore platform in Campos Basin, giving a fast response to operational daily changes.