4368b

advertisement

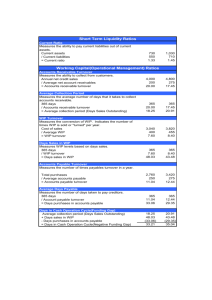

Semiconductor Equipment and Materials International 3081 Zanker Road San Jose, CA 95134-2127 Phone:408.943.6900 Fax: 408.943.7943 SEMI E124-1103 GUIDE FOR DEFINITION AND CALCULATION OF OVERALL FACTORY EFFICIENCY (OFE) AND OTHER ASSOCIATED FACTORY-LEVEL PRODUCTIVITY METRICS 1 Purpose 1.1 This guide describes metrics that show how well a factory is operating compared to how well it could be operating (for the given product mix). These metrics can be used for tracking factory performance (in value-added production) in a way that rewards good operational decisions and that is not easy to adversely manipulate. The metrics can be used in a process of ongoing improvement that can be visible to all levels of a semiconductor manufacturing organization. 1.2 The metrics in this guide are intended for evaluating the relative efficiency of factory production after the factory is in production, not for capacity analysis while the factory is being designed or redesigned. However, some of these metrics can be used in factory simulations for choosing equipment sets and scheduling policies. 2 Scope 2.1 To evaluate the overall effectiveness of a factory, there are at least three things in need of measurement: production, utilization of assets, and costs. This guide focuses on evaluating production. Utilization of assets and costs (as well as other economic factors) are outside its scope. NOTE 1: See ¶ R3-1.1 in Related Information 3 for a discussion of metrics in other areas. 2.2 This guide describes metrics for an entire integrated production line (so, for example, lots may not leave and then return to the production line). Multiple production lines in the same factory may be evaluated separately if they do not share resources (such as material handling or production equipment). NOTICE: This standard does not purport to address safety issues, if any, associated with its use. It is the responsibility of the users of this standard to establish appropriate safety and health practices and determine the applicability of regulatory or other limitations prior to use. 3 Limitations 3.1 In the context of this guide, it is important to note that factory-level productivity is impacted greatly by factors beyond the factory itself, including material availability, efficiency of product device designs, and customer demand. 3.2 The metrics in this guide are intended for evaluating the overall efficiency of factory production, not for diagnosing problems (or opportunities for improvement) in the factory, although some component metrics can be used that way. NOTE 2: See ¶ R3-1.2 in Related Information 3 for a discussion of the differences between the two kinds of metrics. 3.3 This guide provides metrics and calculations for measuring the overall productivity only of manufacturing environments (such as wafer fabs, flat panel factories, and some disk-drive production facilities) in which product substrates move through the factory with no assembly or disassembly processes. These metrics can be applied in a post-wafer back-end chip production facility if the lead frames are considered to be consumable materials (not units of production in their own right). However, in the future this guide may be extended to comprehend other, more complex manufacturing environments (including assembly operations). Also, additional supplemental metrics may be defined, and the metric definitions given here may be expanded to truly comprehend assembly operations. In addition, metrics may be defined that measure fab productivity from the point of view of wafer movement. 4 Referenced Standards and Documents 4.1 SEMI Standards SEMI E10 — Specification for Definition and Measurement of Equipment Reliability, Availability, and Maintainability (RAM) SEMI E79 — Specification for Definition and Measurement of Equipment Productivity NOTICE: Unless otherwise indicated, all documents cited shall be the latest published versions. This is a draft document of the SEMI International Standards program. No material on this page is to be construed as an offi cial or adopted standard. Permission is granted to reproduce and/or distribute this document, in whole or in part, only within the scope of SEMI International Standards committee (document development) activity. All other reproduction and/or distribution without the prior written consent of SEMI is prohibited. Page 9 Doc. 4368 SEMI LETTER (YELLOW) BALLOT DRAFT Document Number: 4368 Date: 3/6/2016 Semiconductor Equipment and Materials International 3081 Zanker Road San Jose, CA 95134-2127 Phone:408.943.6900 Fax: 408.943.7943 5 Terminology 5.1 Abbreviations and Acronyms 5.1.1 CONWIP — Constant Work in Process 5.1.2 COO — Cost of Ownership 5.1.3 GUE — Good Unit Equivalents 5.1.4 OEE — Overall Equipment Efficiency 5.1.5 OFE — Overall Factory Efficiency 5.1.6 THT — Theoretical Production Time 5.1.7 WIP — Work in Process 5.2 Definitions NOTE 3: All the metrics defined below should be calculated with respect to the period being measured. NOTE 4: Several of the metrics defined below are more completely defined in Equations 1 through 22 in ¶ 6.3. 5.2.1 actual throughput rate — the finished units out divided by the total time (shows how fast finished wafers flow out of the factory). 5.2.2 availability efficiency (time divided by time) — the fraction of total time that the equipment is in a condition to perform its intended function (SEMI E79). 5.2.3 average cycle time — the (unweighted) average of cycle time over all of the units of production in finished units out. 5.2.4 average work in process (WIP) — the average cycle time multiplied by the actual throughput rate (shows how many eventually finished units of production fill the “pipeline” on average). NOTE 5: This metric is not an average of the WIP over time because such an average would include units that are later scrapped before finishing. 5.2.5 balance efficiency — the critical WIP divided by the process capacity (measures how well the equipment sets are balanced). 5.2.6 best-case cycle time — the larger of the theoretical cycle time and the quotient of the average WIP divided by the bottleneck throughput rate (shows the best cycle time that the factory can do given the WIP loading). 5.2.7 best-case throughput rate — the smaller of the bottleneck throughput rate and the quotient of the average WIP divided by the theoretical cycle time (shows the best throughput rate that the factory can do given the WIP loading). 5.2.8 bottleneck throughput rate — the upper bound on the factory throughput rate imposed by the current bottleneck equipment set. If a process change for a product causes this metric to change, the product before and after the process change should be considered different products for the purposes of performing these computations. NOTE 6: This metric is similar to (but not the same as) the theoretical unit throughput by recipe metric from SEMI E79. NOTE 7: This metric is not an average over the bottleneck throughput rates of each product. 5.2.9 critical WIP — the theoretical cycle time multiplied by the bottleneck throughput rate (gives the WIP level that theoretically allows the factory to have the highest throughput rate with the shortest cycle time). 5.2.10 cycle time — the amount of time a unit of production spends as WIP in the factory. 5.2.11 finished units out — the number of units of production that finish processing and testing during the period being measured. 5.2.12 good unit equivalents (GUE) out — the (possibly non-integer) number of units of production required to contain all of the good product that exits the factory during the period being measured. 5.2.13 line yield — the fraction of units leaving the factory that have finished processing (measures relative material losses such as scrapped units). 5.2.14 normalized production efficiency — the production efficiency to the power of the normalizing exponent (measures the normalized efficiency of the process with respect to factory dynamics). 5.2.15 normalizing exponent — power that normalizes the production efficiency so that a value of ½ for normalized production efficiency indicates that the factory is performing at the level of the threshold case (which differentiates a well-run factory from one badly operated). This is a draft document of the SEMI International Standards program. No material on this page is to be construed as an offi cial or adopted standard. Permission is granted to reproduce and/or distribute this document, in whole or in part, only within the scope of SEMI International Standards committee (document development) activity. All other reproduction and/or distribution without the prior written consent of SEMI is prohibited. Page 10 Doc. 4368 SEMI LETTER (YELLOW) BALLOT DRAFT Document Number: 4368 Date: 3/6/2016 Semiconductor Equipment and Materials International 3081 Zanker Road San Jose, CA 95134-2127 Phone:408.943.6900 Fax: 408.943.7943 5.2.16 operational efficiency (time divided by time) — the fraction of equipment uptime that the equipment is processing actual units (SEMI E79). 5.2.17 overall equipment efficiency (OEE) (time divided by time) — a metric of equipment performance, expressing the theoretical production time for the effective unit output divided by the total time (CSM 21).1 5.2.18 overall factory efficiency (OFE) — the volume efficiency multiplied by the yield efficiency (shows how well a factory is operating compared to how well it could be operating for the given product mix). 5.2.19 process capacity — the maximum number of units of production that can be processed simultaneously throughout the factory (including units being transported by material handling vehicles). 5.2.20 production efficiency — the throughput-rate and cycle-time efficiency multiplied by the WIP efficiency (measures the efficiency of production with respect to factory dynamics). 5.2.21 quality efficiency (time divided by time) — the theoretical production time for effective units divided by the theoretical production time for actual units (SEMI E79). 5.2.22 scrapped units out — the number of units of production (including broken units, external rework, etc.) that exit the factory without finishing production during the period being measured. 5.2.23 set of bottleneck equipment (Fe*) — the collection of production equipment of the same type that has the highest average operational efficiency in the factory during the period being measured. Elements of this set are indicated by “f”, and the equipment type is indicated by “e*”. NOTE 8: This set of bottleneck equipment might not be the equipment set (often the expensive lithography exposure equipment) that was planned to be the bottleneck in the factory, but rather the equipment set with the highest average operational efficiency (the fraction of time in use when available) during the period being measured. If another equipment set experiences significantly lower availability than expected, it might become the bottleneck. Thus, the sets of bottleneck equipment may be different between two adjacent time periods, and the set of bottleneck equipment for the period combining the two adjacent periods may be different from the other two sets. 5.2.24 set of equipment of type e (Fe) — the collection of production equipment of type eE in the factory. Elements of this set are indicated by “f”. 5.2.25 set of equipment types (E) — the collection of the different types of production equipment in the factory, including metrology equipment and material handling vehicles and conveyors. Elements of this set (which are the different types of equipment) are indicated by “e”. NOTE 9: If units are transported manually between process steps, then the human transporters (and any carts or mechanized vehicles that they operate to perform the movement) should be considered a type of equipment for the purpose of computing the metrics in this guide. This categorization is not intended to dehumanize people, but to ensure that the manual transport time is included in such metrics as theoretical cycle time. 5.2.26 set of process steps of product type p on equipment type e (Spe) — the collection of the different process steps (including metrology inspection and material handling transport) planned for a unit of production of product type p on equipment of type e in the factory. Elements of this set are indicated by “s”. 5.2.27 set of product types (P) — the collection of the different types of products manufactured in the factory. Elements of this set are indicated by “p”. 5.2.28 test yield — the fraction of units leaving the factory that have finished processing and have passed final testing (measures relative losses due to parametric or functional failure). 5.2.29 theoretical cycle time — the minimum time required to process a unit of production through the factory (including material handling transport time) if the unit never has to wait for equipment or a vehicle to become available and if sequence-dependent set-ups never have to be performed. This metric is also known as the raw process time. If a process change for a product causes this metric to change, the product before and after the process change should be considered different products for the purposes of performing these computations. If more than one product (or process flow) is represented in the output, an average is taken over each of the products’ theoretical cycle time weighted by the fraction of that product found in finished units out. NOTE 10: This metric is similar to (but not the same as) the theoretical production time per unit metric from SEMI E79. 5.2.30 theoretical production time per unit (THT) (time per unit) — the minimum rate of time per unit to complete processing, given the following: 1 CSM 21: 95-03 Closed-Loop Measurement of Equipment Efficiency & Capacity, 1995; Engineering Systems Research Center, University of California, Berkeley. Tel: (510) 642-4994. Fax: (510) 643-0966. Web site: http://www.me.berkeley.edu/esrc/_techreports.html. This is a draft document of the SEMI International Standards program. No material on this page is to be construed as an offi cial or adopted standard. Permission is granted to reproduce and/or distribute this document, in whole or in part, only within the scope of SEMI International Standards committee (document development) activity. All other reproduction and/or distribution without the prior written consent of SEMI is prohibited. Page 11 Doc. 4368 SEMI LETTER (YELLOW) BALLOT DRAFT Document Number: 4368 Date: 3/6/2016 Semiconductor Equipment and Materials International 3081 Zanker Road San Jose, CA 95134-2127 Phone:408.943.6900 Fax: 408.943.7943 The specified recipe The equipment design Continuous operation No efficiency losses (SEMI E79) 5.2.31 theoretical throughput rate — the smaller of the bottleneck throughput rate and the quotient of the WIP capacity divided by the theoretical cycle time (gives an unreachable upper bound on the factory throughput rate). 5.2.32 theoretical unit throughput by recipe (THTP) (units per time) — for a given production recipe, the number of units per period of time that theoretically could be processed by the equipment. For each recipe, theoretical unit throughput is equal to the reciprocal of theoretical production time per unit (SEMI E79). 5.2.33 throughput rate — the number of units of production that pass through a process per period of time. 5.2.34 throughput-rate and cycle-time efficiency — the best-case cycle time divided by the average cycle time (shows the relative performance of the factory with respect to throughput rate and cycle time). 5.2.35 total time — all time (at the rate of 24 hours per day, seven days per week) during the period being measured. In order to have a valid representation of total time, all six basic equipment states must be accounted for and tracked accurately (SEMI E10). NOTE 11: For factory-level productivity metrics, total time should be larger than the average cycle time (and is recommended to be twice as large as the average cycle time and larger than the cycle time of any individual unit in finished units out). 5.2.36 unit (of production) — the basic entity in the factory (such as a wafer in a fab, a glass pane in a flat panel factory, or a die in a post-wafer back-end chip production facility) that acts as a product substrate (and moves through the factory with no assembly or disassembly processes). Only product units are included (as opposed to test wafers or other non-product devices). NOTE 12: This definition is more restrictive than that given in SEMI E10 in order to be sufficiently specific. NOTE 13: Production lot sizes can (and typically do) include multiple units of production, and units can (and typically do) contain multiple product devices (usually of the same type but possibly of different types). The user may chose to have the production lot be the unit of production, but this choice is not recommended because the choice of lot size (and its inherent waiting time while its individual units are serially processed) would no longer be a relevant factor in evaluating how well the factory is running; lots can vary in size (even in the same factory); the meaning of unit would be inconsistent with other SEMI standards; scrapped units out would not be properly accounted for. 5.2.37 uptime (equipment uptime) — the hours when the equipment is in a condition to perform its intended function. It includes productive, standby, and engineering time, and does not include any portion of non-scheduled time (SEMI E10). 5.2.38 volume efficiency — the normalized production efficiency times the balance efficiency (measures the total efficiency of the process with respect to factory dynamics). 5.2.39 WIP capacity — the maximum number of units of production the factory can contain (including on shelves, in stockers, on material handling transport vehicles, on equipment load ports, in internal carrier buffers, and in process chambers, but not including space required for non-product units such as test wafers, dummy wafers, and monitor wafers). NOTE 14: This value is not a practical WIP level because it represents total gridlock of the factory. 5.2.40 WIP efficiency — the quotient of the smaller of the critical WIP and the average WIP divided by the larger of the two (measures the efficiency of WIP levels with respect to factory dynamics). 5.2.41 WIP turnover — the finished units out divided by the average WIP (shows how often the inventory was replaced during the period being measured). 5.2.42 work in process (WIP) — the number of units of production that have been released into the factory but have not yet been scrapped, have not been sent out for external rework, and have not finished processing through all of the production steps. 5.2.43 yield efficiency — the line yield times the test yield (shows overall material efficiency). NOTE 15: This metric is similar to (but not the same as) the quality efficiency metric from SEMI E79. 5.3 Symbols This is a draft document of the SEMI International Standards program. No material on this page is to be construed as an offi cial or adopted standard. Permission is granted to reproduce and/or distribute this document, in whole or in part, only within the scope of SEMI International Standards committee (document development) activity. All other reproduction and/or distribution without the prior written consent of SEMI is prohibited. Page 12 Doc. 4368 SEMI LETTER (YELLOW) BALLOT DRAFT Document Number: 4368 Date: 3/6/2016 Semiconductor Equipment and Materials International 3081 Zanker Road San Jose, CA 95134-2127 Phone:408.943.6900 Fax: 408.943.7943 5.3.1 E — set of equipment types 5.3.2 e* — bottleneck equipment type 5.3.3 f — element of an equipment set 5.3.4 Fe — set of equipment of type e 5.3.5 Fe* — set of bottleneck equipment 5.3.6 p — element of a set of product types 5.3.7 P — set of product types 5.3.8 s — element of a set of process steps 5.3.9 Spe — set of process steps of product type p on equipment type e 6 Calculated Metrics 6.1 Figure 1 shows how the metrics defined in § 5 and 6feed into each other. Arrows go from subordinate metrics to the metric in which the subordinate metrics are cited as a part of the primary definition. Shown in the top row (in red rounded rectangles) are the basic building-block metrics for which no equations are needed in this guide; the remaining metrics have equations in this guide that are indicated by the equation numbers in the figure. At the very bottom is the OFE metric into which almost every other metric feeds, although many of the subordinate metrics are useful by themselves(especially if data availability or reliability is a problem). Along the left side (in green rounded rectangles) are the quality metrics that show the efficiency of the process with respect to use of materials. The remainder of the metrics (in blue rectangles) are production metrics that show the efficiency of the process with respect to factory dynamics (without the effects of yield and scrap losses). NOTE 16: Related Information 1 gives an exposition of the underlying science behind these production metrics. 6.2 Unlike overall equipment efficiency (OEE), OFE and its factors are not dimensioned in time divided by time, because not all equipment in the factories is present or operating for the same amount of time. Similar to OEE, this metric is dependent on product mix, process flow, operations, and time period. These dependencies should be considered when comparing different factories or even comparing different time periods in the same factory when the product mix or process has changed (although such comparisons are still valid), especially when the factory variability is due to external factors (such as demand or excess capacity in non-bottleneck equipment); does not comprehend down-stream demand or the varying importance of different products (which might be addressed by a separate metric); varies between zero (total chaos or gridlock) and one (unobtainable perfection); is a product of dimensionless efficiencies. This is a draft document of the SEMI International Standards program. No material on this page is to be construed as an offi cial or adopted standard. Permission is granted to reproduce and/or distribute this document, in whole or in part, only within the scope of SEMI International Standards committee (document development) activity. All other reproduction and/or distribution without the prior written consent of SEMI is prohibited. Page 13 Doc. 4368 SEMI LETTER (YELLOW) BALLOT DRAFT Document Number: 4368 Date: 3/6/2016 Semiconductor Equipment and Materials International 3081 Zanker Road San Jose, CA 95134-2127 Phone:408.943.6900 Fax: 408.943.7943 theoretical production time per unit availability efficiency operational efficiency test yield (7) yield efficiency (3) total time WIP capacity average cycle time actual throughput rate (19) good unit equivalents out (12) line yield (6) finished units out bottleneck throughput rate (17) best-case throughput rate (20) critical WIP (10) theoretical cycle time (16) best-case cycle time (18) average WIP (15) WIP turnover (22) theoretical throughput rate (21) WIP efficiency (14) normalizing exponent (9) throughput-rate and cycle-time efficiency (13) production efficiency (8) normalized production efficiency (4) process capacity (11) balance efficiency (5) volume efficiency (2) overall factory efficiency (1) Figure 1 Definition Tree for Factory-Level Productivity Metrics This is a draft document of the SEMI International Standards program. No material on this page is to be construed as an offi cial or adopted standard. Permission is granted to reproduce and/or distribute this document, in whole or in part, only within the scope of SEMI International Standards committee (document development) activity. All other reproduction and/or distribution without the prior written consent of SEMI is prohibited. Page 14 Doc. 4368 SEMI LETTER (YELLOW) BALLOT scrapped units out DRAFT Document Number: 4368 Date: 3/6/2016 Semiconductor Equipment and Materials International 3081 Zanker Road San Jose, CA 95134-2127 Phone:408.943.6900 Fax: 408.943.7943 6.3 Equations 1 through 22 define the remaining metrics not completely defined in § 5. overall factoryefficiency volumeefficiency yieldefficiency (1) volumeefficiency normalized productionefficiency balanceefficiency (2) yield efficiency line yield test yield normalized productionefficiency productionefficiency balanceefficiency line yield (3) equivalent good units out finished units out scrapped units out normalizingexponent (4) criticalWIP processcapacity (5) finished units out finished units out scrapped units out (6) good unit equivalents out finished units out (7) test yield productionefficiency throughput -rateand cycle-timeefficiency WIPefficiency normalizingexponent 1 (8) (9) averageWIP criticalWIP 1 log 2 min averageWIP , criticalWIP NOTE 17: For x > 0, log2(x) = log10(x) / log10(2) = ln(x) / ln(2). NOTE 18: See ¶ R1-1.7 and ¶ R1-1.8 in Related Information 1 for a derivation of the mathematical expression for the normalizing exponent and for a discussion of the meaning of the threshold case (which differentiates a well-run factory from one badly operated and at which the normalizing exponent causes the normalized production efficiency to have a value of ½). criticalWIP theoreticalcycletime bottleneckthroughputrate (10) numberof tools maximumnumber of units processed process e E average capacity inequipmenttype e simultaneouslyon a tool of equipmenttype e (11) NOTE 19: The symbols e, e*, E, f, F, p, P, s, and S are defined in ¶ 5.2.23 through ¶ 5.2.27. total numberof goodproduct devicesof type p in finished units out good unit equivalents out number of productdevices on eachunit of type p pP throughput -rate and cycle-time efficiency best -case cycle time average cycle time (12) (13) NOTE 20: See ¶ R1-1.6 in Related Information 1 for a discussion of this metric. This is a draft document of the SEMI International Standards program. No material on this page is to be construed as an offi cial or adopted standard. Permission is granted to reproduce and/or distribute this document, in whole or in part, only within the scope of SEMI International Standards committee (document development) activity. All other reproduction and/or distribution without the prior written consent of SEMI is prohibited. Page 15 Doc. 4368 SEMI LETTER (YELLOW) BALLOT DRAFT Document Number: 4368 Date: 3/6/2016 Semiconductor Equipment and Materials International 3081 Zanker Road San Jose, CA 95134-2127 Phone:408.943.6900 Fax: 408.943.7943 WIPefficiency min criticalWIP , averageWIP (14) max criticalWIP , averageWIP averageWIP averagecycle time actualthroughput rate (15) minimum cycle time of number of units of product unit of product type p type p in finished units out ainsingle p P e E s S pe step s on equipment type e theoretical cycle time finished units out finished average number of tools in average availability efficiency units out bottleneck equipment type e * of bottleneck equipment type e * bottleneck throughput rate number of units of theoretical production time per unit product type p in product type p in step s on for bottleneck equipment type e * p P finished units out s S pe* (16) (17) NOTE 21: One of the factors in this metric is the average number of available tools in the current bottleneck equipment set, not the total number of tools nominally in the set. best -case cycle time max theoretical cycle time , average WIP bottleneck throughput rate (18) NOTE 22: See Related Information 1 for why Equations 18 and 20 theoretically represent the best possible cases. actual throughput rate finished units out total time average WIP WIP capacity (19) , bottleneck throughput rate theoretical cycle time best -case throughput rate min , bottleneck throughput rate theoretical cycle time theoretical throughput rate min WIP turnover finished units out average WIP (20) (21) (22) 7 Related Documents 7.1 SEMI Standards SEMI E35 — Guide to Calculate Cost of Ownership (COO) Metrics for Semiconductor Manufacturing Equipment SEMI E58 — Automated Reliability, Availability, and Maintainability Standard (ARAMS): Concepts, Behavior, and Services SEMI E116 — Specification for Equipment Performance Tracking NOTICE: Unless otherwise indicated, all documents cited shall be the latest published versions. This is a draft document of the SEMI International Standards program. No material on this page is to be construed as an offi cial or adopted standard. Permission is granted to reproduce and/or distribute this document, in whole or in part, only within the scope of SEMI International Standards committee (document development) activity. All other reproduction and/or distribution without the prior written consent of SEMI is prohibited. Page 16 Doc. 4368 SEMI LETTER (YELLOW) BALLOT DRAFT Document Number: 4368 Date: 3/6/2016 Semiconductor Equipment and Materials International 3081 Zanker Road San Jose, CA 95134-2127 Phone:408.943.6900 Fax: 408.943.7943 RELATED INFORMATION 1 MANUFACTURING SCIENCE BACKGROUND NOTICE: This related information is not an official part of SEMI E124 and was derived from work by the task force. This related information was approved for publication by full letter ballot procedures on July 27, 2003. R1-1 R1-1.1 To understand the production metrics given in §6 of the main body of this guide, we need to understand the underlying science behind factory dynamics. The most important concept is Little’s Law given in the following equation, which is the same as Equation 15 in §6: R1-1.2 average WIP average cycle time actual throughput rate (R1-1) R1-1.3 In Factory Physics3, this identity is called the “F = ma” of manufacturing science. Little’s Law relates the three most significant fundamental quantities of production systems. Unfortunately, it says that all three metrics cannot be optimized simultaneously. Little’s Law is shown graphically in Figure R1-1. In all of the figures in this Related Information, the colors denote different values of the normalized production efficiency metric with green representing values close to one (at the bottleneck throughput rate and theoretical cycle time), yellow representing values close to ½ (the threshold case as discussed in ¶ R1-1.7), and red representing values close to zero (when the throughput rate goes to zero or the cycle time gets large). On the floor of Figure R1-1 are the linear contours of the cycle time level sets. Note that the boundaries of the operating region are determined by the theoretical cycle time (Tmin), the bottleneck throughput rate (Rmax), and the WIP capacity (Wmax). Figure R1-1 Surface Plot of Little’s Law 3 Wallace J. Hopp and Mark L. Spearman, Factory Physics: Foundations of Manufacturing Management, 2nd ed. (New York, NY: Irwin McGraw Hill, 2001). This is a draft document of the SEMI International Standards program. No material on this page is to be construed as an offi cial or adopted standard. Permission is granted to reproduce and/or distribute this document, in whole or in part, only within the scope of SEMI International Standards committee (document development) activity. All other reproduction and/or distribution without the prior written consent of SEMI is prohibited. Page 17 Doc. 4368 SEMI LETTER (YELLOW) BALLOT DRAFT Document Number: 4368 Date: 3/6/2016 Semiconductor Equipment and Materials International 3081 Zanker Road San Jose, CA 95134-2127 Phone:408.943.6900 Fax: 408.943.7943 actual throughput rate bottleBest Case (throughput-rate neck through- & cycle-time efficiency = 1) put rate (Rmax) Threshold Case (normalized production efficiency = ½) Green Yellow Tmin 1 Red 1/Tmin Worst Case (throughput-rate & cycle-time efficiency = 1/W0) average WIP WIP capacity (Wmax) critical WIP (W0 = RmaxTmin) 1 Figure R1-2 Plot of actual throughput rate vs. average WIP R1-1.4 Looking at two of these fundamental quantities at a time can clarify the factory dynamics. For example, Figure R1-2 above shows actual throughput rate as a function of average WIP levels. Here the diagonal solid black lines represent different constant cycle times, but no known strategy will keep the factory operating exactly on one of these lines. R1-1.5 Now suppose the factory is managed with a push strategy where a constant throughput rate is enforced so that WIP levels are allowed to reach their equilibrium state. As shown below in Figure R1-3, this strategy amounts to choosing to operate the factory on one of the diagonal solid black lines (each of which represent different constant throughput rates). We try to drive the factory along the diagonal line toward the bottom left (for lower average cycle time and average WIP levels) by using better operating principles, but we are resisted by the inherent variability of the factory. R1-1.6 average cycle time Worst Case (throughput-rate & cycle-time efficiency = 1/W0) Threshold Case (normalized production efficiency = ½) Red 1 Tmin Wmax Rmax theoretical cycle time (Tmin) 1 bottleneck throughput rate (Rmax) en Gre w Yello Best Case (throughput-rate & cycle-time efficiency = 1) 1 average WIP critical WIP (W0 = RmaxTmin) WIP capacity (Wmax) Figure R1-3 Plot of average cycle time vs. average WIP This is a draft document of the SEMI International Standards program. No material on this page is to be construed as an offi cial or adopted standard. Permission is granted to reproduce and/or distribute this document, in whole or in part, only within the scope of SEMI International Standards committee (document development) activity. All other reproduction and/or distribution without the prior written consent of SEMI is prohibited. Page 18 Doc. 4368 SEMI LETTER (YELLOW) BALLOT DRAFT Document Number: 4368 Date: 3/6/2016 Semiconductor Equipment and Materials International 3081 Zanker Road San Jose, CA 95134-2127 Phone:408.943.6900 Fax: 408.943.7943 R1-1.7 Now suppose the factory is managed with a pull strategy where a constant WIP level is enforced so that throughput rates are allowed to reach their equilibrium state. In general, this strategy is a better one because studies have shown that a constant WIP level will result in a higher average throughput rate than the constant throughput rate that results in the same average WIP level. As shown below in Figure R1-4, this constant WIP strategy (known as CONWIP) amounts to choosing to operate the factory on one of the solid black curves (each of which represents a different constant WIP level). We try to drive the factory along the curve toward the bottom right (for lower average cycle time and a higher actual throughput rate) by using better operating principles, but we are resisted by the inherent variability of the factory. R1-1.8 average cycle time Worst Case (throughput-rate & cycle-time efficiency = 1/W0) Red critical WIP (W0 = RmaxTmin) WIP capacity (Wmax) Threshold Case (normalized production efficiency = ½) Wmax Rmax theoretical cycle time (Tmin) Yellow Green Best Case (throughput-rate & cycle-time efficiency = 1) 1/Tmin actual throughput rate bottleneck throughput rate (Rmax) Figure R1-4 Plot of average cycle time vs. actual throughput rate This is a draft document of the SEMI International Standards program. No material on this page is to be construed as an offi cial or adopted standard. Permission is granted to reproduce and/or distribute this document, in whole or in part, only within the scope of SEMI International Standards committee (document development) activity. All other reproduction and/or distribution without the prior written consent of SEMI is prohibited. Page 19 Doc. 4368 SEMI LETTER (YELLOW) BALLOT DRAFT Document Number: 4368 Date: 3/6/2016 Semiconductor Equipment and Materials International 3081 Zanker Road San Jose, CA 95134-2127 Phone:408.943.6900 Fax: 408.943.7943 R1-1.9 The following derivation shows why the cycle time efficiency (expressed as best-case cycle time divided by average cycle time) and the throughput rate efficiency (expressed as actual throughput-rate divided by best-case throughput-rate) can both be measured by the same metric (throughput-rate and cycle-time efficiency). The derivation also gives alternative definitions for throughput-rate and cycle-time efficiency for use when cycle time information is not available (such as in resource-based simulations). best -case cycle time -rate and throughput cycle-time efficiency average cycle time average WIP max theoretical cycle time , bottleneck throughput rate average cycle time average WIP max theoretical cycle time , bottleneck throughput rate average cycle time average WIP average WIP theoretical cycle time 1 max , average WIP bottleneck throughput rate 1 actual throughput rate actual throughput rate average WIP min , bottleneck throughput rate theoretical cycle time actual throughput rate best -case throughput rate finished units out total time average WIP theoretical cycle time theoretical cycle time finished units out total time average WIP (R1-2) theoretical cycle time as a fraction of total time WIP turnover R1-1.10 The production efficiency is normalized by the power of the normalizing exponent so that a value of ½ for the normalized production efficiency indicates that the factory is performing at the level of the threshold case (which differentiates a well-run factory from one badly operated). This threshold case is also known as the practical worst case because it represents what the best operating procedures can do in a maximally random factory (see Factory Physics for more on this case). In the threshold case, average cycle time average WIP critical WIP 1 bottleneck throughput rate (R1-3) This is a draft document of the SEMI International Standards program. No material on this page is to be construed as an offi cial or adopted standard. Permission is granted to reproduce and/or distribute this document, in whole or in part, only within the scope of SEMI International Standards committee (document development) activity. All other reproduction and/or distribution without the prior written consent of SEMI is prohibited. Page 20 Doc. 4368 SEMI LETTER (YELLOW) BALLOT DRAFT Document Number: 4368 Date: 3/6/2016 Semiconductor Equipment and Materials International 3081 Zanker Road San Jose, CA 95134-2127 Phone:408.943.6900 Fax: 408.943.7943 which results in the following production efficiency: production efficiency throughput -rate and cycle-time efficiency WIP efficiency average WIP max theoretical cycle time , bottleneck throughput rate WIP efficiency average cycle time max theoretical cycle time bottleneck throughput rate , average WIP WIP efficiency average cycle time bottleneck throughput rate max critical WIP , average WIP min critical WIP , average WIP average cycle time bottleneck throughput rate max critical WIP , average WIP (R1-4) min critical WIP , average WIP average WIP critical WIP 1 bottleneck throughput rate bottleneck throughput rate min average WIP , critical WIP average WIP critical WIP 1 R1-1.11 Thus, if we set normalized production efficiency to have a value of ½ at this average cycle time, we get the following equation: 1 normalized production efficiency 2 production efficiency normalizing exponent min average WIP , critical WIP average WIP critical WIP 1 normalizing exponent (R1-5) Taking logarithms of both sides, min average WIP , critical WIP normalizing exponent 1 log 2 log 2 2 average WIP critical WIP 1 min average WIP , critical WIP normalizing exponent log 2 average WIP critical WIP 1 (R1-6) This is a draft document of the SEMI International Standards program. No material on this page is to be construed as an offi cial or adopted standard. Permission is granted to reproduce and/or distribute this document, in whole or in part, only within the scope of SEMI International Standards committee (document development) activity. All other reproduction and/or distribution without the prior written consent of SEMI is prohibited. Page 21 Doc. 4368 SEMI LETTER (YELLOW) BALLOT DRAFT Document Number: 4368 Date: 3/6/2016 Semiconductor Equipment and Materials International 3081 Zanker Road San Jose, CA 95134-2127 Phone:408.943.6900 Fax: 408.943.7943 we get the following equation: 1 log 2 2 normalizing exponent min average WIP , critical WIP log 2 average WIP critical WIP 1 1 average WIP critical WIP 1 log 2 min average WIP , critical WIP (R1-7) 1 average WIP critical WIP 1 log 2 min average WIP , critical WIP This last expression is the same as in Equation 9 in §6 of the main body of this guide. This is a draft document of the SEMI International Standards program. No material on this page is to be construed as an offi cial or adopted standard. Permission is granted to reproduce and/or distribute this document, in whole or in part, only within the scope of SEMI International Standards committee (document development) activity. All other reproduction and/or distribution without the prior written consent of SEMI is prohibited. Page 22 Doc. 4368 SEMI LETTER (YELLOW) BALLOT DRAFT Document Number: 4368 Date: 3/6/2016 Semiconductor Equipment and Materials International 3081 Zanker Road San Jose, CA 95134-2127 Phone:408.943.6900 Fax: 408.943.7943 RELATED INFORMATION 2 EXAMPLE APPLICATION NOTICE: This related information is not an official part of SEMI E124 and was derived from an example developed by the task force using this guide. This related information was approved for publication by full letter ballot on April 11, 2003. R2-1 R2-1.1 As an example of how the metrics in this guide are applied, the diagram in Figure R2-1 shows the process flow for a grossly simplified model of a wafer fab (developed by Karl Kempf at Intel) that has only five machines in three tool sets, one process flow with six steps, and a single material handling vehicle (that transports 25 wafers at a time). Diffusion Lithography Dry Etch R2-1.2 Figure R2-1 MiniFab Process Flow R2-1.3 The data for this model are shown in the first few columns of Table R2-1 and Table R2-2. A simulation gave the following additional run data: total time = 9 years = 4,733,640 minutes finished units out = 938,571 wafers average cycle time = 1.8 days = 2,592 minutes scrapped units out = 46,929 wafers total units out = 39,420 lots = 985,500 wafers good unit equivalents out = 891,642.1 wafers R2-1.4 In the next-to-last column of Table R2-1, we added together (for each step) all of the times (to load, process batch, unload, and travel to next step) and summed the results to get a theoretical cycle time of 812.4 minutes. In the last column of Table R2-1, we computed the theoretical production time per unit for each step. These values were then used in the last column of Table R2-2 to compute the throughput rate for each equipment set. The throughput rate for the lithography equipment set (0.2182 wafers/minute) is the bottleneck throughput rate, not because it is the smallest throughput rate (It is.), but because the lithography equipment set has the highest average operational efficiency. The remaining metrics are computed on the following pages. R2-1.5 Table R2-1 Table R2-1 Process Data Process Step Number Equipment Set Name Time to Load Batch, minutes Time to Process Batch, minutes Time to Unload Batch, minutes Time to Travel to Next Step, minutes theoretical cycle time (See Note 1), minutes theoretical production time per unit (See Note 2), minutes/wafer 1 Diffusion 20 225 40 8 293 3.0 2 Dry Etch 15 30 15 4 64 1.2 3 Lithography 10 2.2 10 4 26.2 2.2 4 Dry Etch 15 50 15 8 88 2.0 5 Diffusion 20 255 40 4 319 3.4 6 Lithography 10 2.2 10 - 22.2 2.2 - 90 564.4 130 28 812.4 - Sum #1 (theoretical cycle time) = (Time to Load Batch) + (Time to Process Batch) + (Time to Unload Batch) + (Time to Travel to Next Step) #2 (theoretical production time per unit) = (Time to Process Batch)/(Process Batch Size) This is a draft document of the SEMI International Standards program. No material on this page is to be construed as an offi cial or adopted standard. Permission is granted to reproduce and/or distribute this document, in whole or in part, only within the scope of SEMI International Standards committee (document development) activity. All other reproduction and/or distribution without the prior written consent of SEMI is prohibited. Page 23 Doc. 4368 SEMI LETTER (YELLOW) BALLOT DRAFT Document Number: 4368 Date: 3/6/2016 Semiconductor Equipment and Materials International 3081 Zanker Road San Jose, CA 95134-2127 Phone:408.943.6900 Fax: 408.943.7943 Table R2-2 Table R2-2 Equipment Data Equipment Set Number Name in Set Process Batch Size, wafers Buffer Size, wafers Average operational efficiency availability efficiency (each tool) Average availability efficiency bottleneck throughput rate (See Note 1), wafers/minute Diffusion 2 75 450 88% 93% & 97% 95% 0.2969 Dry Etch 2 25 300 78% 81% & 85% 83% 0.5188 Lithography 1 1 300 91% 96% 96% (max!) 0.2182 Transport 1 25 0 69% 62% 62% 0.5536 #1 (bottleneck throughput rate) = (Number in Set) × (Average availability efficiency)/Σ(theoretical production time per unit) WIP capacity Buffer Size Process Batch Size Size of Set eE 450 75 2 300 25 2 300 11 0 25 1 (R2-1) 450 150 300 50 300 1 0 25 600 350 301 25 1276 wafers finished units out total time 938,571 wafers 4,733,640 minutes wafers 0.1983 minute actual throughput rate (R2-2) average WIP average cycle time actual throughput rate wafers 2592 minutes 0.19827 minute 513.9 wafers (R2-3) finished units out average WIP 938,571 wafers 513.9 wafers 1826.3 turns WIP turnover (R2-4) WIP capacity , bottleneck throughput rate theoretical cycle time wafers 1276 wafers min , 0.2182 812.4 minutes minute wafers min 1.5707, 0.2182 minute wafers 0.2182 minute theoretical throughput rate min (R2-5) This is a draft document of the SEMI International Standards program. No material on this page is to be construed as an offi cial or adopted standard. Permission is granted to reproduce and/or distribute this document, in whole or in part, only within the scope of SEMI International Standards committee (document development) activity. All other reproduction and/or distribution without the prior written consent of SEMI is prohibited. Page 24 Doc. 4368 SEMI LETTER (YELLOW) BALLOT DRAFT Document Number: 4368 Date: 3/6/2016 Semiconductor Equipment and Materials International 3081 Zanker Road San Jose, CA 95134-2127 Phone:408.943.6900 Fax: 408.943.7943 average WIP , bottleneck throughput rate theoretical cycle time wafers 513.9 wafers min , 0.2182 812.4 minutes minute wafers min 0.6326, 0.2182 minute wafers 0.2182 minute best -case throughput rate min best -case cycle time max theoretical cycle time , (R2-6) average WIP bottleneck throughput rate 513.9 wafers max 812.4 minutes, wafers 0.2182 minute max 812.4 minutes, 2355.5 minutes (R2-7) 2355.5 minutes NOTE 17: For this average WIP level, the best-case cycle time was not determined by the theoretical cycle time, but by the bottleneck throughput rate. Thus, a simple metric like (average cycle time)/(theoretical cycle time) underestimates how well the factory is doing. best -case cycle time average cycle time 2355.5 minutes 2592.0 minutes 90.88% throughput -rate and cycle-time efficiency (R2-8) critical WIP theoretical cycle time bottleneck throughput rate wafers 812.4 minutes 0.2182 minute 177.3 wafers processcapacity (R2-9) maximumnumber of units processed averagenumberof tools inequipmenttype e simultaneouslyon a tool of equipmenttype e e E 2 75 2 25 1 1 1 25 wafers (R2-10) 150 50 1 25 wafers 226 wafers WIP efficiency min critical WIP , average WIP max critical WIP , average WIP min 513.9, 177.3 wafers max 513.9, 177.3 wafers (R2-11) 177.3 wafers 513.9 wafers 34.49% This is a draft document of the SEMI International Standards program. No material on this page is to be construed as an offi cial or adopted standard. Permission is granted to reproduce and/or distribute this document, in whole or in part, only within the scope of SEMI International Standards committee (document development) activity. All other reproduction and/or distribution without the prior written consent of SEMI is prohibited. Page 25 Doc. 4368 SEMI LETTER (YELLOW) BALLOT DRAFT Document Number: 4368 Date: 3/6/2016 Semiconductor Equipment and Materials International 3081 Zanker Road San Jose, CA 95134-2127 Phone:408.943.6900 Fax: 408.943.7943 productionefficiency throughput -rateand cycle-timeefficiency WIPefficiency 0.9087 0.3449 (R2-12) 31.34% normalizing exponent 1 averageWIP criticalWIP 1 log 2 min averageWIP , criticalWIP 1 513.9 177.3 1 wafers log 2 min 513.9, 177.3 wafers 1 690.2 wafers log 2 177.3 wafers 1 log 2 3.894 (R2-13) 1 1.961 0.5099 normalized productionefficiency productionefficiency 0.5099 0.3134 normalizingexponent (R2-14) 55.35% criticalWIP processcapacity 177.3 wafers 226 wafers 78.43% balanceefficiency volumeefficiency normalized productionefficiency balanceefficiency 0.5535 0.7843 (R2-15) (R2-16) 43.41% good unit equivalents out finished units out 891,642.1 wafers 938,571.0 wafers 95.00% test yield (R2-17) This is a draft document of the SEMI International Standards program. No material on this page is to be construed as an offi cial or adopted standard. Permission is granted to reproduce and/or distribute this document, in whole or in part, only within the scope of SEMI International Standards committee (document development) activity. All other reproduction and/or distribution without the prior written consent of SEMI is prohibited. Page 26 Doc. 4368 SEMI LETTER (YELLOW) BALLOT DRAFT Document Number: 4368 Date: 3/6/2016 Semiconductor Equipment and Materials International 3081 Zanker Road San Jose, CA 95134-2127 Phone:408.943.6900 Fax: 408.943.7943 finished units out finished units out scrapped units out 938,571 wafers 938,571 wafers 46,929 wafers (R2-18) 938,571 wafers 985,500 wafers 95.24% yield efficiency line yield test yield 0.9524 0.9400 (R2-19) 90.48% overall factoryefficiency volumeefficiency yield efficiency 0.4341 0.9048 (R2-20) 39.27% This is a draft document of the SEMI International Standards program. No material on this page is to be construed as an offi cial or adopted standard. Permission is granted to reproduce and/or distribute this document, in whole or in part, only within the scope of SEMI International Standards committee (document development) activity. All other reproduction and/or distribution without the prior written consent of SEMI is prohibited. Page 27 Doc. 4368 SEMI LETTER (YELLOW) BALLOT line yield DRAFT Document Number: 4368 Date: 3/6/2016 Semiconductor Equipment and Materials International 3081 Zanker Road San Jose, CA 95134-2127 Phone:408.943.6900 Fax: 408.943.7943 RELATED INFORMATION 3 SUPPLEMENTARY INFORMATION NOTICE: This related information is not an official part of SEMI E124 and was derived from work by the task force. This related information was approved by full letter ballot procedures on April 11, 2003. R3-1 R3-1.1 As mentioned in ¶ 2.1, there are at least three things in need of measurement in a factory: production, utilization of assets, and costs. This guide focuses on evaluating production; utilization of assets and costs (as well as other economic factors) are outside its scope. For measuring effectiveness of asset use, an average (over all of the equipment in the factory) of OEE weighted by COO can be defined in some other document. However, the use of consumables, utilities, and human resources would still need to be comprehended. For measuring costs, some other new standard might define a new metric (similar to COO) for the cost of factory ownership expressed in such metrics as $/(good wafers), $/(good chips), $/(metal levels), $/(good transistors), $/circuit, or $/bit. R3-1.2 As mentioned in ¶ 3.2, the metrics in this guide are intended for evaluating the overall health of the factory production, not for diagnosing problems (or opportunities for improvement) in the factory, although some component metrics can be used in that way. These metrics should indicate whether the factory is running poorly (much like taking a person’s temperature indicates whether the person is ill) while some of its components and other diagnostic metrics might indicate what the cause of the problem is (much like doing a blood analysis in the lab identifies the disease). The following are examples of metrics not in this guide that can be used for diagnosis: Ratio of turns to WIP at key operations or for blocks of operations Overall WIP distribution Daily starts and output Defect density Throughput, utilization, and available up-time of bottleneck equipment NOTICE: SEMI makes no warranties or representations as to the suitability of the standards set forth herein for any particular application. The determination of the suitability of the standard is solely the responsibility of the user. Users are cautioned to refer to manufacturer's instructions, product labels, product data sheets, and other relevant literature, respecting any materials or equipment mentioned herein. These standards are subject to change without notice. By publication of this standard, Semiconductor Equipment and Materials International (SEMI) takes no position respecting the validity of any patent rights or copyrights asserted in connection with any items mentioned in this standard. Users of this standard are expressly advised that determination of any such patent rights or copyrights, and the risk of infringement of such rights are entirely their own responsibility. REVISION RECORD NOTICE: The following information is provided to track revisions to this document. Negative votes may not be cast against this information. Changes can be submitted to SEMI staff via a Publication Improvement Proposal (PIP) form. Cycle Authorization Section Description This is a draft document of the SEMI International Standards program. No material on this page is to be construed as an offi cial or adopted standard. Permission is granted to reproduce and/or distribute this document, in whole or in part, only within the scope of SEMI International Standards committee (document development) activity. All other reproduction and/or distribution without the prior written consent of SEMI is prohibited. Page 28 Doc. 4368 SEMI LETTER (YELLOW) BALLOT DRAFT Document Number: 4368 Date: 3/6/2016