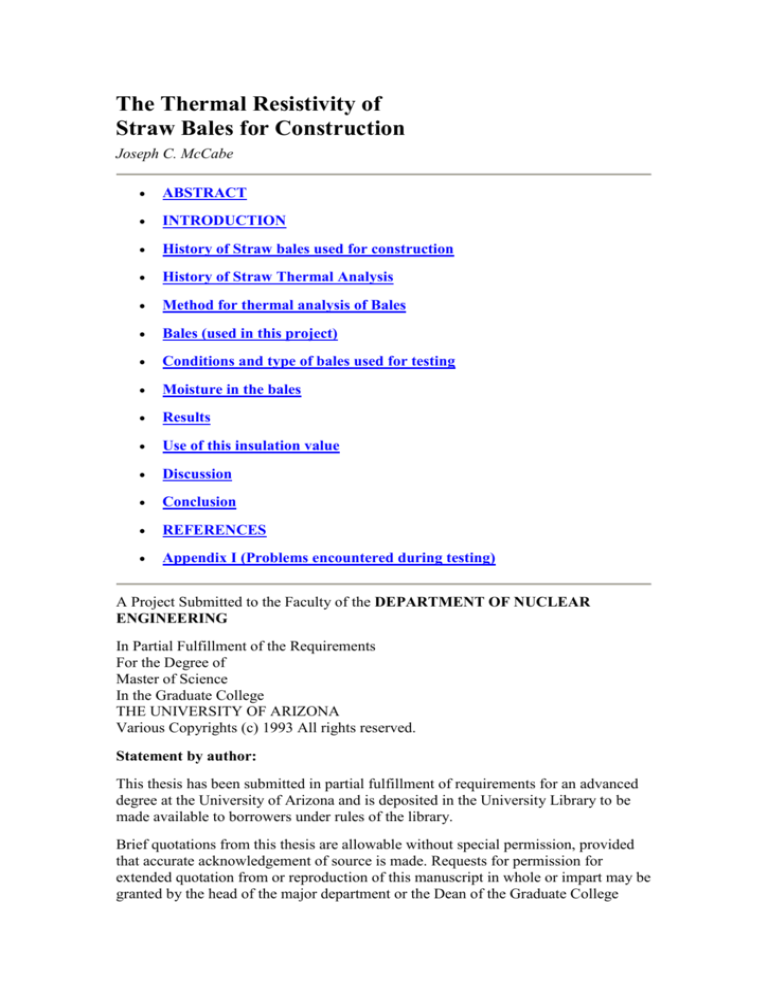

The Thermal Resistivity of

Straw Bales for Construction

Joseph C. McCabe

ABSTRACT

INTRODUCTION

History of Straw bales used for construction

History of Straw Thermal Analysis

Method for thermal analysis of Bales

Bales (used in this project)

Conditions and type of bales used for testing

Moisture in the bales

Results

Use of this insulation value

Discussion

Conclusion

REFERENCES

Appendix I (Problems encountered during testing)

A Project Submitted to the Faculty of the DEPARTMENT OF NUCLEAR

ENGINEERING

In Partial Fulfillment of the Requirements

For the Degree of

Master of Science

In the Graduate College

THE UNIVERSITY OF ARIZONA

Various Copyrights (c) 1993 All rights reserved.

Statement by author:

This thesis has been submitted in partial fulfillment of requirements for an advanced

degree at the University of Arizona and is deposited in the University Library to be

made available to borrowers under rules of the library.

Brief quotations from this thesis are allowable without special permission, provided

that accurate acknowledgement of source is made. Requests for permission for

extended quotation from or reproduction of this manuscript in whole or impart may be

granted by the head of the major department or the Dean of the Graduate College

when in his judgement the proposed use of the material is in the interests of

scholarship. In all other instances, however, permission must be obtained from the

author.

Acknowledgements:

I would like to thank the following for help in this thesis:

Lou Thompson for his brains, Matts Myhrman for his movement, University of

Arizona Environmental Research Laboratory for the facilities, Dr. Nader Chaulfoun

for his data, Dr Alphonso Ortega and Dr. Coates for their knowledge, Dr. Rocco

Fazzolari, Dr. William Fillipone and Dr. John Peck for their review and their

assistance.

And, mostly, thank you Dr. Cynthia Erickson for everything!

Dedication:

This thesis was written for all those who can benefit from the use of straw materials

for buildings, everyone.

ABSTRACT

This thesis describes the procedure for obtaining an insulation value for straw bales

for construction. A modified hot plate was placed between two bales and temperature

readings were taken at various locations in and on either sides of the straw bales, this

is referred to as a "modified guarded hot plate procedure".

An R-Value of 52 (H-FT^2-F/BTU-Bale) was determined for wheat bales. Rice straw

bales have similar insulating value. This R-value was used to demonstrate the energy

requirements of a residential building constructed with straw bales. The use of this

value has wide ranging implications on energy use for buildings. In order to compare

straw bale insulation to more traditional insulation materials the Arizona home energy

rating program, CalRes, was used. An average residential building energy usage

decrease of 12.4% per year was determined by using straw bales.

Straw is an anisentropic material. Insulating values of bales varies with position. Heat

flow against the grains has a higher insulating value (R=3.15/inch) than heat flowing

with the grains (R=2.38/inch). Moisture content and bale density also effect insulating

values.

INTRODUCTION

This thesis attempts to explain the history of straw bale construction; the problem of

no known values for the thermal resistivity of straw bales for construction; how

experimentally a value of the thermal resistivity was determined; and what this

insulating value can do for typical building designs.

History of Straw bales used for construction

The history of straw bale construction is an important portion of this thesis because it removes the

"Three Little Pigs" attitudes to this building technique.

Information from Out On Bale, Unlimited, a straw bale construction consulting firm

located in Tucson indicates the use of grass as a building material dates back to the

Stone Age, by which time humans were making extensive use of the enormous

grassland areas of the African and European continents.

The next logical progression toward bale buildings would be the use of such bundles

of stems as units to build a wall. Out On Bale, Un-Limited is presently trying to

confirm the existence, in Great Britain (Cheshire), of a slightly more than twohundred year old residence reportedly constructed by laying up long, tied bundles of

straw with an earthen mortar.

Nebraska residents have used straw for a building material for over 100 years.

Although there was a negative social stigma attached to living in a building made of

straw, these homes were practical, inexpensive efficient and sturdy. In fact several are

still standing today. Nebraska Historical Society located in Lincoln Nebraska has a

file on straw bale buildings in various counties in west and north Nebraska. Pictures

#1-3 show various views of these existing structures in Nebraska.

[5.1k]

[5.6k]

[6.7k]

Photos courtesy of Nebraska Historical Society, Lincoln Nebraska.

Straw bale construction flourished in the Sandhills of Nebraska more than any known location. Straw

was one of the only indigenous materials available to the sandhills area of northwest Nebraska. Bale

construction was an appropriate, sometimes necessary, response to a unique combination of legislative,

geologic, natural resource and socio-economic factors that prevailed in that region in the early 1900's.

The Kincaid Act of 1904 opened up the part of Nebraska that includes the Sandhills to

homesteading under new rules. Applicants could claim a full section (a one mile

square) rather than the quarter section previously allowed. This act brought large

numbers of financially pinched homesteaders into a nearly treeless, semi-arid region

characterized by vast areas of roadless, rail-less, grass-stabilized sand dunes.

Many inhabitants said that they, or others, had built bale houses as a temporary, stopgap measure to get the family under roof in the shortest possible time for the least

possible money. Many of them planned to build a "real" house as soon as enough

money could be saved. Such houses were often left exposed on the outside, while

plastered on the inside to enhance tidiness and prevent drafts. When the owners

finally believed that they were living in a "real" house, a process that sometimes took

as much as ten years, the outside walls would finally get a thick coat of mud plaster or

cement stucco. .1

As of this date (3/18/93), Out On Bale Un-Limited has solid documentation on eightyfive bale structures built since 1940, in Mexico, the United States, Canada and

Finland.

Climatically, the range of building sites includes semi-arid, southern Sonora, Mexico;

rainy, humid Alabama; wintry northern Alberta, Canada; and the coast of Maine. The

buildings run the gamut from a 10' by 12' storage shed, built by a 5th grade class with

rice straw bales, to an art gallery, to a 40' by 80' grocery store, to elegant homes, to a

26,000 square foot hog barn with a straw-insulated roof..2

Building of Railroads through the midwest is one factor that added to the reduction of

straw use. Railroads and merchandizing enabled wood products to replace Nebraska's

indigenous materials for buildings needs.

There has been a renewed interest in straw bale material because of environmental

interests and changing social values.

Recent renewed interest in straw bale construction makes engineering properties

associated with the material a necessity. What insulating value should be applied to

the straw bale wall? Energy designs can be compared with this important

characteristic. Sophisticated computer programs such as Calpas and DOE2 as well as

state energy rating programs such as Arizona's CalRes can predict the energy

consumption of a building using the known R-values. It is believed that this

information has not been available for straw bales previously.

The Department of Energy (DOE) estimates are that the home heating and cooling

energy usage in this country is 11% of the total U.S. energy consumption..3 Total

U.S. consumption was 74.2 Quadrillion BTU's in 1983..4 The straw bale insulating

material has great potential to reduce the residential sector building energy usage.

Houses built with straw bales have been constructed at costs of $20 to $75 per square

foot depending upon the sweat equity and extravagance of design compared to $45$75 of conventional home costs. Photographs 4 and 5 show the before workshop and

after views of a recent wall raising just south of Tucson downtown. This wall raising

took 3 hours to accomplish with the help of about 25 workshop participants.

[172k]

[179k]

{A post thesis note here, this bale structure burnt to the ground a few weeks after this picture was

taken. Located in the barrio district of Tucson, it highlights the need for immediate stucco for fire

proofing and precautionary steps.}

Bales don't provide great reductions in construction costs compared with conventional

building practices; however bales provide society with a reduced cost associated with

the environment and health. Agricultural wastes are typically burned; the straw bale

construction creates a demand for this material and reduces the burning. Recent

proposed California legislation will prohibit the burning of rice straw material. It is

possible that other states will enact similar legislation for other materials posing

threats to the environment.

The high thermal efficiency of straw bales reduce the energy requirements for heating

and cooling thus reducing pollution associated with energy to heat and cool dwellings.

This is an inexpensive high insulating material which does provide cost economies in

comparison with conventional high insulation costs. Bales can be a pollution

abatement program; the sequestering of yesterdays pollution in todays straw material.

Other value is to our old growth forests; trees can remain standing if the biannually,

renewable crop of straw is used as a replacement building material. The structural

capabilities of straw bale walls has been addressed in a 1993 paper by Galen Bouali a

civil engineering graduate student at the University of Arizona.

History of Straw Thermal Analysis

An extensive review of published materials uncovered articles on straw and straw

board materials in relation to the thermal and sound absorbing properties.

Published thermal properties of paddy straw particle boards were available in a paper

Mechanical and Thermal Properties of Particle Boards Made from Farm Residues.

Low- density particle board specimens with the following specifications were made

using ureaformaldehyde resin 6% (w/w) as the binding material, hot pressed under

1.47 MPa pressure and 170 C temperature for 15 minutes.

Board Size 0.225 X 0.25 X 0.016 m = 8.86" X 9.84" X .63"

Moisture content 11- 14 %

Particle size 5 - 10 mm long

Density 190 kg m^3 = 11.86 lbs/ft^3

The thermal properties were:

Porosity 55 %

Thermal Conductivity 226.0 Jm^-1h^-1C^-1= .0363 BTU/h-Ft-F= R value of 27.57/Ft

(R=2.29 h-Ft^2-F/BTU-in, similar to mineral fiberboard)

Specific heat 753.5 J kg^-1 C^-1 = 0.1799 BTU/lbm-F

Diffusivity: 44.46 10^-8 m^2 s^-1= 0.1724 Ft^2/h .5

These values include the bonding material and are not exactly representative

properties of the bales. The procedure for the testing to determine these numbers is

not known. Actual testing results from this project indicate that this R=2.29 h-Ft^2F/BTU-in value is close to the insulating value of bales with heat flowing with the

grains of the straw of R=2.38 h-Ft^2-F/BTU-in.

The Canada Mortgage and Housing Corporation, Housing Technology Incentives

Program, in Ottawa, Ontario, Canada has information on an innovative straw/bale

mortar wall system which describes the results of testing done in Canada on a sample

wall created by laying up straw bales (460mm or 18- 1/2" wide) with a cement-limesand mortar. A mixture of the same materials was then plastered onto each side to

create a layer 20mm (3/4") thick. These results indicated an average moisture content

of 13.36% and an insulative quality (RSI 6.17 or R-35)..6 As with the previous article

the procedure for this testing is not available.

Method for thermal analysis of Bales

Testing has followed to my best ability the guidelines set out by the American Society

for Testing and Materials ASTM, 1991 Standard Test Method for Steady-State Heat

Flux Measurements and Thermal Transmission properties by Means of the GuardedHot-Plate Apparatus. This test method covers the achievement and measurement of

steady-state heat flux through flat-slab specimens using a guarded-hot-plate

apparatus..7 It is used for board insulation, batt insulation and flat-slab specimens.

The testing was modified such that there was no cold plate. The cold plate was

replaced by sheet metal surfaces providing room temperature across the surface.

There was also no guard; the hot plate was surrounded by the insulating materials.

A special opportunity was available for me to use an adobe building at the

Environmental Research Laboratory near the airport in Tucson. A beautifully

landscaped facility provided a comfortable atmosphere for testing as well as

appropriate monitoring capabilities. Adobe mass provides a constant temperature

room to conduct testing. Temperature swings from 71.3 to 68.7 F dry bulb ( delta

temperature of 3.1 F) on March 18th and 19th were typical for the small temperature

swings throughout the beginning testing periods. Temperature swing of 2.6 F was

obtained during steady state conditions for the bundle on March 28th. The adobe

building came equipped with wet bulb, dry bulb and room radiant monitoring

equipment. These data points, bale thermocouple and heat flux sensors were wired

into the Omega portable datalogger, Model OM-372. This was linked via RS-232 to

an IBM-XT terminal where information was logged using Procomm communications

software running under DOS. Data was transferred to spreadsheet using Lotus and

computations and graphing performed by QuatroPro. Average reading values were

used for computations and graphing.

U of A Environmental Research Labratory[93k]

Thermocouple are T-type, blue and red insulation. Calibration of thermocouple was

performed using a calorimetric thermometer graduated at .2 degrees from 0 to 214

degrees F, a corrections table generated and applied to the data logger. Heat flux

sensors are Hycal Engineering B1- 7-120.

Computations for insulating properties was performed using ASTM Designation: C

1045 - 90 Standard Practice for Calculating Thermal Transmission Properties From

Steady-State Heat Flux Measurements..8

Testing was performed on blue polystyrene as a control (R-value of 5/inch) which

was compared to rice and wheat straw bales.

Bale bundles were the heart of the testing, for bales making up a bundle. Bundles

were produced in a systematic procedure. Plastic milk cartons were used to elevated

the bundles from the conduction of the adobe building brick floor. Banding straps

were placed on top of the milk cartons and taped in place for future banding

requirements. White painted 44" X 45"- 26 gauge sheet metal was place on top of the

milk cartons and straps. This standard white paint gave the surface an emissivity of

0.9. The first two bales were placed on the sheet metal. The heat source wrapped in

aluminum foil to distribute the heat and was centered upon the two bales. Four

thermocouple were Elmers glued to the heat source aluminum foil, two on the top and

two on the bottom at 6" away from the center lengthwise. The particular bale which

would have its internal temperature was placed on top of the first bale and the portion

of the heat source under it. This bale was carefully measured for thermocouple

placement. A pair of thermocouple was placed at the levels of 2", 5" and 10" from

heat source, . Thermocouple were also place on the internal surface of the bale to

determine the heat flow in the crack between the bales. The last bale was placed to

make the bundle. Three thermocouple were placed on the top surface of the bales. For

the wheat straw bundle a heat flux meter was placed on the top surface in the center of

the bundle. One piece of sheet metal was placed on the top, and the bundle was

banded together with 4 straps. Sheet metal was placed on the 4 sides remaining and

banded in place. Corners of the bundle had portions of straw materials showing

through the sheet metal. This was required so the bundle could be compressed by the

banding procedure. All thermocouple wires were exiting the bundle at the same

location while following constant heat flux paths in the interior of the bale bundle.

Pictures # 7 shows actual testing in the adobe building.

[168k]

Additional information obtained during testing was the volume of bales weight of

bales, the density and the percent moisture of bales being tested.

Not in the original report but for the net here we have animations of the testing. Click

on these images if you have FLI capabilities or Quicktime.

[463k Quicktime movie]

[120k FLI animation]

Temperature readings were at the heat source, bale surface, and at different levels in

the bales, 2", 5", and 10" from the heat source. Other testing included thermocouple

placed at the 1", 2", 3", 4.5", 6", 10" and surface positions. Heat flux metering was

placed at the heat source, 4.5" 10" and surface levels.

Room temperature, room wet bulb and dry bulb temperatures as well as room globe

temperatures were obtained.

Steady state operation was determined when the hot plate heat source did not vary

more than 1 degree F for a one day period. Voltage and current measurements were

obtained to the heat source.

The test procedure was to examine bales for consistency, record bale external

characteristics, and to measure the bale dimensions and weight.

The bales were positioned for cubic configurations such that the heat source is

sandwiched between two bales. The dimensions of the end of the heat source and the

bale surface dimensions were confirmed. This were used in edge loss and shape factor

corrections analysis.

The main goal was to obtain constant temperature readings through out a sample test

area of the bale. This was accomplished in steady state form after days of heating the

interior of the test module bundle. Testing indicated steady state operation was

obtained many days and in the case of the rice straw, weeks after the heating began.

Thermocouple were placed on the heat source and at various levels of the bale, and at

the bale surface. The placement of thermocouple was suggested by ASTM C 1045909 with at least 2 thermocouple at each level.

The energy to the heat source was regulated so the temperature remains constant. This

was done with a DC power supply. The heat source is a radiant heat panel by Aztec.

This normal 200 watt rating 15" X 23.5" panel was attached to a 25 volt DC power

supply to regulate power to the heating device. The voltage and current is measured

with a Fluke model 8012A and a Hewlet Packard model 6215 A.

The DC power supply regulated the power into the hot plate for straw high

temperature testing at

Voltage=25.3 Volts DC

Current=0.341 Amps

For a wattage of (V*I)=8.63 Watts=29.4 BTU/hr

Power was reduced for the polystyrene testing and low temperature bale testing. The

heat flux metering was used for determination of actual heat flow in the bales and

polystyrene tests.

Thermocouple were calibrated before using. Voltage corrections for specific

thermocouple were programed into the Omega data logger. Temperature readings

were logged on 10 minute intervals. When the hot plate temperature no longer varied

more than 1 degree for the day average steady state condition was assumed. A delta

temperature across the bale was measured and applied to the equations for insulating

value.

Background on bales used in this project

Bales from farms have varying volumes and banding schemes. New Mexico bales are

typically 2 band, Yuma bales are 3 plastic wraps. 3 plastic wrap norther California

rice straw bales were shipped for this experiment. Bales of various materials are

available. Straw comes from rice, oats, wheat, etc. The bales used for this project

were rice straw bales and wheat straw bales.

Bales range in size from 50 to 80 lbs and sizes 35"-47" long, 14-16.5" high and 18"23" wide..10 Drawing # 1 illustrates these dimensions. These dimensions orientation

the fibrous material of the bale horizontal. Bales have been oriented in various

positions in building construction. Testing the properties was done in the horizontal

and vertical positions. If the bales of a wall are vertical straw materials the wall

thickness (16.5" heat flow against the grain) is less than if the straw is horizontal (23"

heat flow with the grain) and there is less insulating value per inch. The heat flow

during comparison testing was perpendicular to the strands of straw, the 16.5"

dimension or height of bale. Testing was also performed on the bales to determine 23"

length insulating value, called "on end" testing. Typical building practice uses either

orientation.

These bale tests were compared with the same test method performed on pieces of 4"

thick polystyrene, having a known insulating value of R=5 h-Ft^2-F/BTU-in. These

pieces of polystyrene were positioned for a cubic arrangement of 48" X 48" X 32",

similar to the bale cubic arrangement. These comparisons provide similar edge and

corner loss comparisons.

Conditions and type of bales used for testing

This thesis used two different types of straw materials. Wheat straw bales were

obtained from a warehouse in Tucson. Rice straw bales were shipped from Northern

California. All bales had been unused, 3 string bales dimensions and weight of the

bales used as shown in Table # 1.

Weight of bales and density were measured in an attempt to follow the ASTM

Thickness and Density of Blanket or Batt Thermal Insulations..11 This method had

applicable guidelines for proper apparatus, however the batt insulation expansion

procedure was not applicable because of the varying surfaces of the bales; the bale

length is shorter where the ties are, the bales bend and have pockets of straw sticking

out. To the best extent accurate measurements were performed, however all

dimensions should have a + or - 1/2" discrepancy because of difficulty in

measurements.

The method for bale moisture has not been addressed with standard procedural

process. It is a unique measurement for our applications.

Conditions and type of bales used for testing

This thesis used two different types of straw materials. Wheat straw bales were

obtained from a warehouse in Tucson. Rice straw bales were shipped from Northern

California. All bales had been unused, 3 string bales dimensions and weight of the

bales used as shown in Table # 1.

Weight of bales and density were measured in an attempt to follow the ASTM

Thickness and Density of Blanket or Batt Thermal Insulations..11 This method had

applicable guidelines for proper apparatus, however the batt insulation expansion

procedure was not applicable because of the varying surfaces of the bales; the bale

length is shorter where the ties are, the bales bend and have pockets of straw sticking

out. To the best extent accurate measurements were performed, however all

dimensions should have a + or - 1/2" discrepancy because of difficulty in

measurements.

The method for bale moisture has not been addressed with standard procedural

process. It is a unique measurement for our applications.

Moisture in the bales

Testing performed for this thesis represents a small sample of bales. Bales used for

construction should have the driest possible conditions for greatest insulating value.

Dry bales have higher insulating values than bales with moisture because the moisture

migration transfers heat.

Wheat straw has 28% moisture content when fresh cut weight, rice straw 20%..12

Typical bales have 14% moisture. However the industry does not track statistics for

moisture percentage values. Two types of moisture values are important to the

agricultural industry. First is the quality, dry bales last longer and don't rot. The

second is marketing. Marketing is important because of the value of the straw not the

water. Bales are penalized for being wet..13 The moisture content is important in

determining the insulation properties of the bale material without the effect of water,

moisture. The method for determining water content or this thesis was to break open

the center of a bale, and obtain a representative sample of the interior straw. This

straw was weighed, and heated for days at 100 C, then weighed again. The difference

of the weights is the moisture removed. The bale was banded together and used in the

test bundle.

Percent moisture of bales were obtained before and after the testing of the wheat

bales. Percent moisture tests of a the rice straw bales which were dried on a sun porch

at a temperature of 103-110 F during sunny days provided an 8.4% moisture content.

The percent moisture test of the rice straw used in the thermal testing was determined

after the testing of the test bundle bales.

TABLE # 1

Straw Bale Characteristics

Bale Type

#

1

Wheat

2

Wheat

3

Wheat

4

Wheat

Average

St. Dev.

5 Rice

6 Rice

7 Rice

8 Rice

Average:

Std. Dev.

Bale

#

1

2

3

4

5

6

7

8

Wheat Ave

Rice Ave:

Dim (in inches)

Weight

%

hgt

wth

length

lbs

Moisture

16.7

22.5

44.4

84

8.4%

16.7

22.5

44.5

80

8.4%

16.0

23.5

47.0

83

8.4%

16.3

23.0

46.7

84

8.4%

16.4

22.9

45.6

82.7 8.4%

+.34

+.48 +1.39 +1.89

16.5

23.0

45.5

77

8.2%

15.5

23.5

44.5

76

8.2%

16.5

23.0

45.5

79

8.2%

16.5

23.0

44.5

71

8.2%

16.2

23.1

45.0

75.7 8.2%

+.5

+.25

+0.6

+3.4

Volume

Density

ft^3

lbs/ft^3

19.68

8.68

9.71

8.24

10.23

8.12

10.14

8.28

10.03

7.68

9.42

8.07

10.03

7.88

9.80

7.24

9.94+.29

8.33+.24

9.82+.29

7.72+.36

Percent moisture was one of the biggest problems in obtaining a steady state

condition. This problem provides information regarding the typical bales used for

construction. Materials are cut in the field and laid out to dry. The length of time

material stays in the field depends upon the weather; ideally it is collected and baled

in its driest possible state. Wheat bales tested 8.2 to 8.4 % before and 5.9% after the

bundle thermal testing; this shows that drying out during the testing. It has been the

findings of this experiment that the straw samples do not dry out more than 5%

moisture when the heat is applied for extended periods. Bales could have been placed

in ovens and dried at extreme temperatures, but this would not provide typical

building material information. It was assumed that the material reaches an equilibrium

of moisture content dependent upon relative humidity and temperature. See Appendix

for more information on problems during testing.

Results

The steady state condition took a long time to achieve because of moisture problems

in the bales. The rice straw had considerable moisture, taking two weeks to reach a

steady state condition. The values of temperature readings for the horizontal position

of the rice and wheat straw bales are:

TABLE # 2

3_28_93 Horizontal after steady state, rice straw, average temperatures of

thermocouple readings:

Hot Plate 2" Ave. 5" Avg. 10" Avg.Surf

Average: 142.9 123.7

108.3

89.5 70.5

Minimum: 142.6 123.5

108.2

89

68.3

Maximum: 143.2 123.9

108.5

89.7 72.7

Room W.B. Room D.B

Average:

59.3

67.8

Minimum:

58.8

66.3

Maximum:

60.1

68.9

4_6_93 Horizontal after steady state, wheat Straw average temperatures of

thermocouple readings:

Hot Plate

Ave 144.4

Max 144.8

Min 143.8

2" Ave

131.1

131.5

130.5

5" Avg

109.0

109.5

108.3

10" Ave

90.0

90.3

89.8

Surf Ave.

76.0

77.2

74.9

Room W.B. Room D.B.

Ave:

Min

Max:

61.1

62.4

59.9

69.9

71.6

68.3

These tests are illustrated in the Graph # 1 "Rice Straw, Horizontal Steady State

3_28_93 Ave Temps" and Graph # 2 "Wheat Straw Horizontal Steady State 4_6_93

Average Temperatures".

[7.2k]

[6.7k]

It was found that a temperature versus distance graphing of the test provided near

straight line relationship from the hot plate to the 6" level in the straw bundles. This

can be seen in the graph Temp vs Distance 4_18 Wheat Low Temp, Graph #3.

[5.6k]

Polystyrene insulation with a known insulation value of R=5/inch was tested in the

same manner as the bales. An R- value of 4.9 was experimentally determined in the

bundle configuration using heat flux measurements at the 4.5" level and a delta

temperature of hot plate minus the 4.5" level. This same method was used on wheat

bales in the horizontal, low and high delta temperature and "on end" positions.

Graphical representation of these comparative tests are shown in Graph #4, #5, & #6.

The results for these tests are as follows:

[5.6k]

[5.6k]

[5.6k]

TABLE #3 Results of Bale Bundle Testing Compared With Polystyrene

Type

q

Delta

u

R for

of

Temp

4.5"

Bale

Wheat 2.33 31.0 0.075 13.3

Wheat 1.39 19.7 0.071 14.2

Low Temp

Poly- 1.44 31.9 0.045 22.2

styrene

Wheat 1.59 17.0 0.09 10.7

on end

R for R for

1"

Bale

2.96

3.15

48.8(16.5")

52.0(16.5")

4.93

2.38

54.8(23")

Units are: q-(BTU/FT^2-H), u-(BTU/FT^2-H-F), R-(H-FT^2- F/BTU-inch)

Graph # 7, R-Value per inch illustrates these results.

[5.6k]

Use of insulation value

Typical building design analysis information is available to compare conventional

building techniques with the straw bale. For this thesis I have performed computer

energy simulations of existing designs which are presently being built and meet

current Arizona energy use requirements. These simulations are done with a program

called CALRES/Arizona, a computer program developed for the Arizona Energy

Office by Berkley Solar Group Software for the Arizona Home Energy Rating

System.

CALRES/Arizona is a design tool used to compare design strategies. For this project

the high insulation properties of the straw bale is compared with the typical R-11 and

R-19 wall insulation used in todays buildings. The exterior convection, interior and

exterior surface materials remain unchanged. These data files were obtained from a

study for Southwest Gas performed by Dr. Nader Chaulfoun at the University of

Arizona Department of Architecture. The names of the construction designs have

been withheld because of their unimportance to this thesis; the important information

is the energy usage comparison of existing building techniques to that of the straw

bale construction. Building designs were chosen at random for small to medium size

structures. Tucson Arizona is the weather file used, the worst case orientation to the

sun was used with the largest window facing west. There were no stucco or adobe

surfaces applied to the simulation, only the inside and outside convection with an

R=52 insulation value.

A review of the results are:

TABLE # 4

Calres Arizona Comparison of Homes

Weather Data Tucson AZ.

Calres Arizona Comparison of Homes

House

#

SQ. FT.

1

1211

2

1132

3

1400

4

1305

5

1596

6

1504

7

1523

Original (kBtu/ft2-yr)

Heating Cooling Total

23.02

23.78

46.8

28.81

69.32

98.13

17.57

38.12

55.69

16.54

34.62

51.16

14.32

36.13

50.45

14.28

39.38

53.66

23.6

23.17

46.77

Weather Data Tucson AZ.

House

With

#

Heating

1

18.33

2

23.49

3

14.83

4

14.71

5

12.87

6

12.44

7

18.06

Straw (kBtu/ft2-yr)

kBTU/yr

Cooling Total Savings %savings

21.21

39.54

8791

15.5%

60.82

84.31

15644 14.1%

34.34

49.17

9128

11.7%

31.59

46.3

6342

9.5%

33.73

46.6

6144

7.6%

36.21

48.65

7535

9.3%

19.79

37.85

13585 19.1%

Average:

12.4%

This is a significant decrease in energy usage.

Discussion

Insulation value of straw bales for construction has great implications for reducing

residential energy consumption. The Department of Energy predicts that energy end

use in U.S. residential and commercial buildings for space heating and cooling was

9.5 quadrillion BTU's in 1990 and will be over 11 Quadrillion Btu's in the year 2010.

In Tucson Arizona the percentage of residential energy usage for cooling is much

higher than the national average at 49%, lower for heating at 16%. This energy usage

is what straw bale construction can reduce without reducing comfort or air changes

per hour.

Recently there have been laws created to ban the burning of field straw. This material

is currently a waste product for the farmers. Along with these laws, high disposal

costs will increase usage of straw for construction.

Conclusion

Straw bale construction has high insulating value of R=52 for a 16.5" bale width with

typical home temperatures. Rice straw is similar to wheat straw in its insulating value.

The positioning of straw bale does have an effect on the insulating value of the bale.

Heat traveling against the grains of the straw has a greater insulating value that heat

traveling with the straw grains. Home energy usage can be reduced by 12.4% by using

this building material.

This project demonstrates the great impact straw bales can have on the residential

energy usage heating and cooling usage. Utility companies can benefit from this

reduction in conduction of heat when the need to reduce energy usage is greatest,

when it is hot out. Typical demand side management DSM programs look for

opportunities to reduce the peak energy usage of the year so that new power plants

don't have to be constructed for this peak energy usage. Straw bale construction can

help to reduce this peak energy usage, as well as bring the whole yearly demand curve

down.

The Thermal Resistivity of

Straw Bales for Construction

Joseph McCabe

References

1 Myhrman, Matts, interviewed by Joseph McCabe, Tucson, AZ., 2 P.M., April 6,

1993RETURN

2 Myrman, Matts, April 22, 1993 Architecture and the Great Plains: The Built

Environment, Past and Present symposium. Work in progress.RETURN

3 Mcpherson, E. Gregory, "Benefits and Costs of Energy- Conserving Site Design",

American Society of Landscape Architects, 1984RETURN

4 U.S. Department of Energy/ Energy Information Administration (1992) Annual

Energy Outlook 1984 (DOE/EIA-0383(84)) Washington, D.C.: U.S. Government

Printing Office II.RETURN

5 A. Sampathrajan, N.C. Vijayaraghavan & K.R. Swaminathan, "Mechanical and

Thermal Properties of Particle Boards Made from Farm Residues", Bioresource

Technology 0960-8524/92 p 249-251RETURN

6 Canada Mortgage and Housing Corporation, Housing Technology Incentives

Program, Ottawa, Ontario, Canada, K1A OP7. 1984. An innovative straw/bale mortar

wall system. NHA 577 84/08.RETURN

7 ASTM, Designation : C 177 - 85 1991 Standard Test Method for Steady-State Heat

Flux Measurements and Thermal Transmission properties by Means of the GuardedHot-Plate Apparatus. Volume 04.06 p. 20RETURN

8 ASTM Designation: C 1045 - 90 Standard Practice for Calculating Thermal

Transmission Properties From Steady-State Heat Flux Measurements. Vol, 04.06, p

538 RETURN

9 Ibid, ASTM C-1045-90 Vol 04.06 p. 542

10 MacDonald, Stephen O., "Straw Talk & Tech Tips", The Last Straw, Tucson, AZ

Fall 1992 p. 7RETURN

11 ASTM 1991 Thickness and Density of Blanket or Batt Thermal Insulations. C 167

p. 11 Vol.04.06RETURN

12 Risser, Paul G., "Agricultural and Forestry Residues", Biomass Conversion

Processes for Energy and Fuels, Plenum Press, NY., p. 36.RETURN

13 Larson, D.L., interviewed by Joseph McCabe, University of Arizona, Agricultural

Engineering, Tucson, AZ., 2 P.M. 3/30/93RETURN

Appendix I

Problems encountered during testing

This section is included to help those who wish to further the study of the thermal properties of straw

bales. The intent is to have learned from the mistakes made during this study.

Straw is an anisentropic material. The insulating value is different if heat is flowing

with the grains of the straw or against it. For the testing this provided problems in

determining constant heat flux lines. The heat flux would radiate out from the heat

source in a 3-dimensional pattern. Heat flux was not constant at different levels in the

bale or polystyrene materials. A cold surface was installed to force the flux in a

specific direction with no additional beneficial effect, in fact it made the heat flux in

the center of the bale less than it had been without the cold surface. The straw sample

was surrounded by polystyrene having twice the insulating value, however the heat

continued to flow from the insulation up to the cold plate as well as from the heat

source out to the insulation giving very low heat flux measurements in the center of

the straw sample.

The radiant heater panel had slight fluctuations across the face. This is a conducting,

resistive material with positive power lengthwise on the ends and negative in the

center. Aluminum foil was wrapped around the flat heating material to increase the

consistent heat distribution at the heating source.

The placement of thermal sensors was difficult. Straw is a nonhomogeneous material.

To get the best measurements a temperature sensing probe placement should be exact.

The area surrounding the thermocouple needed to be the same density of material as

the total bale. A placement of sensor in between, or on the surface of the bales was

not an accurate representation of the temperature in the bale. After conducting

numerous weeks of testing it was determined that 3" into the bale seemed to provide a

good representation of temperature. Bale dimension measurements are difficult to

within plus or minus one half an inch. The solution was to produce a probe which

would not effect the measurements but allow for exact placement. I used a bamboo

skewer which had the 24 gauge T type thermocouple glued to it every 2". The

skewers were pushed into the bale, horizontally. The long stick enabled the horizontal

placement at a vertical placement required. The skewer was broken at the point the

bale surface was reached; sacrificed for exact placement of the thermocouple. The

skewer appear to be similar to the straw material; placed along constant heat flux

lines. Four thermocouple were placed directly on the heating source, two on top and

two on bottom, two thermocouple were placed at the 2", 5" and 10" levels both 4" of

center line and 6" off center line, then 3 thermocouple were placed on the surface of

the bale bundle just under the sheet metal, once again at 4" off center line, 6" off

center line and one directly at the center of the heating panel below.

Water content of the bales was a difficult parameter to determine. Tests on the rice

bales left on the hot sun porch indicated a 8.4% moisture. Rice bales used for steady

state thermal testing conditions had a 8.2 % moisture. Wheat bales tested 8.2 to 8.4 %

before and 5.9% after the bundle thermal testing; this shows that drying out during the

testing.

After testing of the Rice bale bundle the compression bands were removed, water had

condensated under the sheet metal face, the rice straw bales were "wet" with moisture

there. This moisture was less than 1" deep into the bale. Apparently this did not affect

the steady state condition of the testing because steady state was maintained for the

horizontal and vertical testing.

Horizontal versus vertical placement of the bales changed the temperature readings.

This is evident in the graph # 9 "Vertical Rice Straw Bales, 3_29_93 2", 5", 10"

levels". The probes didn't move; temperature readings changed directions depending

upon if they were on the top of the vertical center line or on bottom. The higher

placed thermocouple had correspondingly higher readings. This was also the case at

the heat source as seen in the Graph # 10 "Vertical Rice Straw Bales 3_29_93 Hot

Plate Temperatures". The temperatures were higher at the top of the hot plate than at

the bottom, and temperatures throughout the bale were correspondingly lower the

lower the thermocouple placement.

Bale bundle exterior temperatures were not as constant for the top of the horizontal

bundle as for the bottom. An Omega Radiant Heat gun temperature reading device

showed that the top of the bundle was 75-76 degrees while the bottom was 70-71

degrees. This demonstrates the effect of moisture in the bale and possibly the effect

the colder floor had on the heat transfer of the bale bundle.

It was seen from the vertical testing that there are convection effects in the bales at the

heat source. When turned on its side, the hot plate temperatures are drastically

effected. This can be seen in the differences in two graphs, Rice Straw, Horizontal

Steady State for 3_28_93 Graph # 1 thermocouple readings in layers and the "Vertical

Rice Straw Bales 3_29_93 2", 5" 10" levels" Graph # 10. When turned on its side, the

physically lower thermocouple readings were a lower temperature than the physically

higher temperature readings. This is illustrated in the graphs.

A guarded hot plate apparatus was used without reduction of the heat flux losses. A

polystyrene box was constructed which surrounded a straw sample with an R=80 wall

insulating value. An ice bath was used as a cold surface. The heat flux still varied at

different levels throughout the sample indicating a loss of flux to the polystyrene box.

A hot wire technique was tried. This provided good results for polystyrene samples as

well as styrofoam, however, the contact between the straw and probe provided wrong

results for the insulation value of the straw. This technique was abandoned.

Corner and edge loss factors as well as three dimensional effects make the theoretical

analysis of the cubic bundle arrangement difficult. A shape factor can be used to

account for these effects. These calculations indicated an R value of R=58 for the

horizontal bales. The previously determined method is more reliable.