technical analysis of wheat straw

advertisement

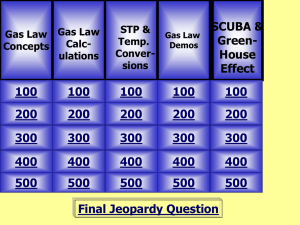

POLJOPRIVREDNI FAKULTET NOVI SAD KINETIC COMBUSTION OF WHEAT STRAW BALES Prof. dr Todor Janić Dr Saša Igić, doc. Prof. dr Miladin Brkić AIM OF THE RESEARCH The aim of this experimental research work is aimed at determining the fullest functional dependencies, ie. correlation equations which represent the mathematical modeling of the interaction between multiple variable factors on the combustion process baled wheat straw in furnaces with stationary flat grate. ELEMENTARY CHEMICAL ANALYSIS OF WHEAT STRAW The elemental composition of wheat straw: C+H+O+N+S+A+W=1 TECHNICAL ANALYSIS OF WHEAT STRAW Wheat straw in terms of technical analysis has the following characteristics: burns with a large amount of volatile matter (from 57,2 to more than 80%); in composed almost no sulfur; burns with little ash (5 to 8%), which is problematic because of solubility at temperatures below od 800oC. ignition temperature is about 220oC; low heat value of straw is in the range of about 14 MJ/kg, with straw moisture content of 14%; moisture content in straw is changeable, and proper storage conditions is in the range of 1015%. INFLUENTIAL FACTORS ON THE COMBUSTION PROCESS FACTORS OF INFLUENCE ON THE BURNING RATE The characteristics and concentration of reactants; Pressure; Temperature; Influence of catalyst and others. INFLUENTIAL FACTORS ON THE COMBUSTION RATE IN THE FIREBOX Types of furnaces; Combustion technology; Physico-chemical characteristics of the fuel; PHASE OF WHEAT STRAW COMBUSTION Stages of combustion are: Drying - endothermic process where fuel is receiving heat for evaporation of moisture. Distillation - gasification of fuel when the fuel vaporize all volatile components - volatiles. Combustion - combustion process of solids is performed in the third phase on the grid. Dogorevanje - the continuation of the third stage, but on a smaller scale. Combustion stages overlap and their length is variable on what influenced by many factors (type of fuel, their caracteristic, etc.). THERMAL DESTRUCTION OF WHEAT STRAW Decrease in mass Increase in temperature Temperatura (oC) Masa (mg) Drying of fuels from 80-90oC Hidden decomposition from 90-200oC Devolatisation intense from 270-370oC Reduction in burning rate from 370-550oC Significant reduction in burning rate - over 550oC Time (min) MATERIAL USED IN RESEARCH The material used in this paper are selected bales of wheat straw. Straw that was used in the study was collected from the same field in Kać. Average cross-section of straw bales was due to the chosen strainer and amounted to about 0,37 x0,50 m, while in order to get as similar length bales (approximately 0,70 m) made their selection on the field. On the field was allocated 300 bales. INFLUENCING FACTORS ON COMBUSTION OF WHEAT STRAW Work plan are considered two factors: the density of straw bales and excess air ratio in the combustion of straw. The first factor was investigated at three levels, and second in four levels. As the levels of the factors of bale density are: low, normal and high-density with initial weight of the bale of 5, 7 and 9 kg. Coefficient of excess air factor selected size are: 1,8; 2,3; 2,8 i 3,3. This work has the dimension of multiple factor experimental research. In this way enabled the simultaneous application of mathematical statistics to examine the field dependence of the kinetics of the combustion process resulting influence of selected factors, their levels, and their mutual influence (interaction). 1 - electric motor, 2 - fan 3 - air schedulers, 4 - damper, 5 - tube for air intake below the grille, 6 damper, 7 - Upper air intake pipe above the tank, 8 and 9 - metering orifice 10 - grid , 11 - scales, 12 - air supply pipe above the tank, 13 acquisition device, 14 - flue gas analyzer, 15 - computer, 16 - probe for the analysis of combustion products, 17 - damper, 18 - thermal couple for measuring tempetatura heated water , 19 - chimney, 20 - hot water boiler (40 kW), 21 - "U" tube for measuring pressure, 22 - port to measure pressure in the boiler, 23 thermal probe, 24 - pipe for heated water, 25-thermal couple for measuring the temperature of the water coming out of the boiler, 26 heat accumulator, 27 - water pump, 28 - overflow pipe, 29 - bowl for regulating the temperature of incoming water into the boiler, 30 pipe for water supply from hydrants, 31 - door ashtrays CHART OF MEASURING Ambijent air Straw THE MEASUREMENT RESULTS V_2,3_I M_1,8_I M_3,3_I S_2,8_II 10,00 V_2,3_II M_1,8_II M_3,3_II S_2,8_I V_2,8_I M_2,3_I S_1,8_I S_3,3_I V_2,8_II M_2,3_II S_1,8_II S_3,3_II V_3,3_I M_2,8_I S_2,3_I V_1,8_I V_3,3_II M_2,8_II S_2,3_II V_1,8_II 9,00 Masa bal e (kg) ( kg) of bales Mass 8,00 7,00 6,00 5,00 4,00 3,00 2,00 1,00 0,00 1 246 491 736 981 1226 1471 1716 1961 2206 2451 2696 2941 3186 3431 3676 3921 Time Vr eme (s) ( s) MATHEMATICAL MODEL WHICH DESCRIBES MASS REDUCTION BALE WHEAT STRAW COMBUSTION IN THE PROCESS OF THEIR FIREBOX WITH FLAT IMMOVABLE GRATE m 5,53 0,272 1,286 e 0, 0016 6 MATHEMATICAL MODELS DESCRIBING THE MASS REDUCTION OF WHEAT STRAW BALES EACH OF COMPACTION OBSERVED IN THE PROCESS OF THEIR COMBUSTION IN THE FIREBOX WITH FLAT IMMOVABLE GRATE m M 7 ,89311 1 ,37254 e 0 ,011039 6 mY 10 ,37717 1 ,55648 e 0 ,0034305 m B 12 ,82155 1 ,30865 e 0 ,0014672 6 6 CONCLUSIONS The modifications of the boiler, it is possible to directly monitor "decline" mass burning bales of straw. Analysis of variance confirmed the significance of the density bales of wheat straw and the excess air coefficient of combustion Defined mathematical models that describing the kinetics combustion of baled wheat straw on a flat immovable grate. of Obtained depending on the intensity of a comprehensive mathematical model is significant. This, among other conclusions can be drawn based on the value of the correlation coefficient is R = 0,8882. It also defines special forms of mathematical models, which are available for an average weight loss of straw bale for each bale density level. Further work in this area should be directed towards determining the intensity and direction of temperature gradient and the mass of straw bales, coupled with an increase in their porosity during combustion, and the impact of the way (up-down ratios) of air penetration , as layer of straw bales, and exhaust combustion products.