Integrated fuzzy MCDM based on LCA results for industrial waste

advertisement

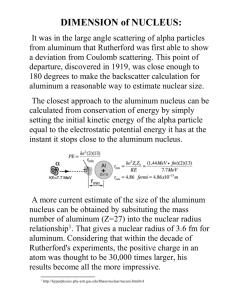

Integrated fuzzy MCDM based on LCA results for industrial waste management R. Zare*1 J. Nouri1, M. A. Abdoli2, M. Alavi3 , F. Atabi1 1Department of environment management, faculty of energy and environment, science and research Branch, Islamic Azad University, Tehran, Iran; 2Faculty of environment, university of Tehran; of Mathematics, Arak Branch, Islamic Azad University, Arak, Iran 3Department * Corresponding Author: E-mail: r.zare@srbiau.ac.ir Abstract: The global secondary aluminum production grows rapidly because of the environmental considerations and continuous growing of the consumption demands as well. Aluminum dross recycling, as secondary aluminum process has been always considered as a problematic issue in the world. The aim of this work is to propose a methodical and easy-to-use algorithm for the proposed system selection as a MCDM problem. In this study, an integrated fuzzy AHP model is developed in order to assess aluminum waste management systems. For this purpose, we drive weights of each pairwise comparison matrix by the use of the goal programming model. The functional unit includes aluminum dross and aluminum scrap, which is defined as 1,000 kg. The model is confirmed in the case of aluminum waste management in the industrial city of Arak. For the proposed integrated fuzzy AHP model, five alternatives are investigated. The results showed that, according to the selected attributes, the best waste management alternative is the alternative involving the primary aluminum ingot 99.5% include 200 kg and the secondary aluminum 98% (scrap) include 800 kg. So the beneficiation activities are implemented, aluminum dross is recycled again in the plant and finally it is landfilled. Key words: Aluminum waste, Dross, FAHP 1. Introduction: Nowadays, aluminum is used in industry, transportation, construction and packaging industries, more increasingly. In aluminum industries, the secondary aluminum production grows rapidly due to the pertaining to the environment considerations and growing of the consumption demands. It is estimated that the production of this material will reach 2.60x107 t in 2015 (Hong et al., 2010). In this paper, FAHP methodology has been considered to evaluate the environmental, economic, and social impacts of the aluminum waste. This approach allowed us to mathematically represent the uncertainty to reflect the decision maker’s perception to decision making process as well. The arrangement of the rest of this study is as follows: In section two, we review some literatures about the proposed problem. In section three, as methodology, we review some basic concept and finally the proposed algorithm is explained. In section four, we present a case study related to the aluminum waste is provided. The study ends with a discussion and conclusion. 2. Literature review: The production of aluminum from bauxite needs much more energy than other metals and leads to large quantities of greenhouse gas emissions (Norgate and Jahanshahi, 2011). Aluminum production is 1 responsible for 1.1% of the annual greenhouse gas emissions (Liu et al., 2013). It is about 75% of all the aluminum production as secondary aluminum since 1880s is still in generative use. The findings of these studies indicated that the emissions and energy consumption of aluminum were decreased in the production of the secondary aluminum compared to the production primary aluminum (Liu and Müller, 2012). Authors represented that the aluminum waste recycling is an economic and environment friendly (Shinzato and Hypolito, 2005). By recycling the secondary aluminum, resources are saved, the need for landfill area could have been decreased and the public’ thought would be satisfied. Although aluminum dross is a waste of current resources but on the condition it is landfilled without suitable treatment and it causes the secondary contaminants which would effect on air, water and soil (Hong et al., 2010). The environmental impact by aluminum dross from the secondary aluminum should be minimized. That is why in this study, the effects and impacts of aluminum waste management systems are evaluated. In addition, aluminum dross recycling is always considered as a problematic issue. Fuzzy set idea was used by (Weckenmann and Schwan, 2001) to manage uncertainty in the inventory data. Since Van Laarhoven and Pedryezand (Van Laarhoven and Pedrycz, 1983) presented their initial study in FAHP, many works applied FAHP in different environment problems (Weck et al., 1997, Abdi, 2009, Chan et al., 2013, Wang et al., 2012). Also, some studies applied FAHP method concerning LCA thinking. For example, this methodology applied by Zhang in the building sector (Zheng et al., 2011), and by Hing and Lin to evaluate green product design (Hing Kai et al., 2013) (Lin et al., 2013). Complex decision-making situations are relevant to the aluminum waste management system which needs the understanding of different sectors within the industry and society. However, little attention has been given to the environmental aspects of the processing output of aluminum dross and aluminum scrap as aluminum waste in the MCDM methodologies. 3. Methodology The aim of this work is to present a systematic method for the aluminum waste management option selection problem. Methods were evaluated for this purpose, including as follows: fuzzy logic, group decision making, goal programming method and the fuzzy AHP. 3.1 Fuzzy number (FN) FN is a method to illustrate the ambiguity and the missed crisp data (Zadeh, 1965). The decision makers present fuzzy opinion in place of crisp opinion for a pairwise comparison. 3.2 The nearest weighted interval approximations ( NWIAs ) We achieve the interval approximations for a FNs (Izadikhah, 2012). 3.3 Group Decision making A group of experts who have high levels of awareness and experience in the proposed waste management systems were used to propose the criteria. Then, a survey was conducted through the distribution of a questionnaire among the decision makers group to determine the importance weights of the criteria and ratings of the alternatives. Decision makers are five experts from the production managers of the proposed industries and academic centers in the Environment and Management fields who contribute to the decision-making process. The relative importance of each attributes and the preferences of the decision makers are transformed to the triangular fuzzy numbers. We use 0-1 and 0-10 scale to express their opinions independently on the rating of the criteria and alternatives with respect to the criteria. 3.5 Goal Programming The goal programming attempts to combine optimal logic and the preference of decision makers in the arithmetical programming in order to satiate the several goals. This means that, the goal programming presents the way for concurrent goal attainment (Tzeng and Huang, 2013). 3.6 Driving the Weight of Criterion In case of ambiguity, and for driving the weight of each criterion from the inconsistent fuzzy matrix, we act as the following method (Izadikhah, 2012). Step 1: We transform the fuzzy matrix A to an interval matrix A . 2 Step 2: We achieve the optimum weight vector W w1 , w2 , w3 showing the importance of each criterion. In order to solve the problem, we apply the linear programming software LINGO 11. The detailed mathematics are found in Appendix A 3.7 FAHP method AHP approach applies multi-criteria decision analysis developed and presented by Saaty (Saaty, 1988)) to compute the weighting factor of the criteria. The AHP method cannot handle the uncertainty in deciding the ratings of different attributes (Chan and Kumar, 2007). In FAHP method, the judgments are made using linguistic parameters which are characterized by fuzzy membership functions. If there is more than one expert involved in judging process, the different matrices are combined together to form one synthetic matrix. 3.8 Proposed algorithm The proposed integrated AHP, goal programing and NWIA algorithm determine the most preferable aluminum waste management system selection among all possible alternatives, when data is fuzzy, is given as follows: Step 1: Set up the expert group. To evaluate alternatives, an expert group comprised of researchers and managers should be established; Step 2: Create a hierarchical structure of the elements for the problem solving. For this propose, it is necessary for the decision makers to determine criteria and sub-criteria based on the proposed main target. Step 3: Build a set of fuzzy pairwise comparison matrices for each decision maker; Step 4: Aggregate fuzzy pairwise comparison matrices. We aggregate fuzzy pairwise comparison matrices constructed by the decision makers by using geometric mean method and to convert them to unit fuzzy pairwise comparison matrix. Step 5: Derive the weights of each matrix. For this purpose, apply the following sub steps: Sub-step 5.1: Convert each fuzzy matrix to an interval fuzzy matrix. Sub-step 5.2: Calculate the weight of each pairwise comparison matrix; Step 6: Aggregate the weights and rank the alternatives. We aggregate the weights and rank the alternatives to select the best aluminum waste management system. 4. Case study: A case study on aluminum industries and particularly aluminum remelter plants in Arak industrial area center of the Islamic Republic of Iran is presented. It illustrates how the proposed fuzzy AHP methodology according to above descripted algorithm can be applied to selecting the best aluminum waste management system. Twenty-nine re-melting facilities were incorporated in this research. The secondary aluminum re-melting is considered as a unit function. As shown in figure 1, this process unit includes the storage in place (1), beneficiation activities (2) related to input aluminum scrap such as washing, separating and sorting (or without beneficiation activities (3)), remelting in aluminum crucible furnace (4), duplicate aluminum black dross recycling in plant (5) (or export aluminum black dross to other place and duplicate recycling (6)), and final waste landfill (7) (or release in the environment (8)). 3 (3) (1) Aluminum Industries Skimming Aluminum dross Storage (7) Aluminum Ingot (4) (2) (5) (emission to air) (6) (8) (emission to water) (emission to watersoil) Figure 1: Flowchart of the secondary aluminum re-melting in proposed research All the results are based on the reference flow of 1 ton of aluminum batch include new and old aluminum scraps and dross. The upkeep and repair of the plant and equipment materials are provided to this lifecycle stage from both primary and secondary aluminum processing. Also, the secondary remelters have a diversity of melting furnaces: top-loaded closed, rotary, and side well-feeding melting. They have different competences. In this study, the crucible furnace for the secondary aluminum re-melting is used. In this study, firstly, a panel of experts as decision maker group was set up. The decision makers were five experts: Three engineers from the production managers of the aluminum industries, and two academics in the Environment and Management fields. Then, the documents including literature, financial documents, statistics of the occupational accidents and diseases, the results of overviews and primary life cycle assessment were evaluated by the decision makers using fuzzy linguistic terms. This approach allowed us to mathematically represent the uncertainty and vagueness and reflect the decision maker’s perception to decision making process. After this, a questionnaire was distributed to decision makes to evaluate and determine the importance weights of the criteria and ratings of the alternatives. Once the responses were received, the questionnaire results were checked and interviews were conducted to ensure the data validity. Figure 2 shows the decision hierarchy for the decision making problem. In the upper ranks of the hierarchy we have the general objective that in this case is the selection of an aluminum waste management system. We presented the main criteria including environmental, social and economic aspects at level 2. The associated general attributes or sub-criteria (level 3) are the main criteria. These general attributes are broken-down into global warming (GWP), human toxicity (HTP), land use (LU), health and safety at work (H&S), regulation (Reg), turnover and gain. At level 4, we showed the five management alternatives. aluminum waste management system selection Criterion C1 Criterion C3 TurnoverC31 GWP C11 Gain C32 Alternative E Alternative D LU C12 Alternative C Criterion C2 ETP C13 Alternative B H&S C21 Reg C22 Alternative A Figure 2: The hierarchical structure in the proposed research Five management alternatives for aluminum waste management in the city of Arak are presented as follows: Alternative A aluminum crucible for re-melting aluminum batch include the primary aluminum ingot 99.5% include 200 kg and the secondary aluminum 96% (scrap) include 800 kg, beneficiation 4 activities related to input aluminum scrap such as washing, separating and sorting, export aluminum black dross to other place and duplicate recycling, landfill. Alternative B aluminum crucible for re-melting, aluminum batch include the primary aluminum ingot 99.5% include 200 kg and the secondary aluminum with grade 96% (scrap) include 800 kg, remelting without beneficiation activities, export remain aluminum black dross to other place and duplicate recycling, release in environment. Alternative C aluminum crucible for re-melting aluminum batch include the primary aluminum ingot 99.5% include 200 kg and the secondary aluminum 96% (scrap) include 800 kg, beneficiation activities related to input aluminum black scrap such as washing, separating and sorting, duplicate aluminum dross recycling in plant, landfill. Alternative D is defined as the present current aluminum waste management system: aluminum crucible for re-melting, aluminum batch include the primary aluminum ingot 99.5% include 200 kg and the secondary aluminum 96% (scrap) include 800 kg, re-melting without beneficiation activities, export aluminum black dross to other place and duplicate recycling, release in environment. Alternative E aluminum crucible for re-melting, aluminum batch include the primary aluminum ingot 99.5% include 200 kg and the secondary aluminum 98% (scrap) include 800 kg, beneficiation activities related to input aluminum scrap such as washing, separating and sorting, duplicate aluminum black dross recycling in plant, landfill. Alternative A is defined as the 'intermediate' waste management system. Alternative B is defined as the current waste management system. It is similar to alternative A, but instead of landfill method, the aluminum waste is released in environment. Alternative C represents 'business' option where economic benefits are more important. Alternative D represents 'waste export' where approximately 70% of aluminum waste that is normally landfilled, are exported to other place for duplicate recycling. Alternative E is defined as the environment friendly aluminum waste management system. The results interval approximation matrices were presented in tables 1-5. Table 1: The interval approximation main target concerning the gain criteria Main target C1 C2 C3 Obtained Weights C1 [1,1] [5.7,6.8] [5.7,6.8] 0.84507 C2 [0.15,0.18] [1,1] [4.5,5.5] 0.126761 C3 [0.15,0.18] [0.18,0.23] [1,1] 0.028169 Table 2: The interval approximation sub-criteria concerning the environmental criterion Environment C11 C12 C13 Obtained Weights C11 [1,1] [2.36,2.96] [1.09,1.37] 0.633438 C12 [0.32,0.42] [1,1] [2.71,3.51] 0.267838 C13 [0.76,0.93] [0.30,0.38] [1,1] 0.098724 Social C21 C22 Table 3: The interval approximation sub-criteria concerning the main criteria C21 C22 Weights Economic C31 C32 [1,1] [2.7,3.1] 0.754717 C31 [1,1] [3.68,4.73] [0.32,0.47] [1,1] 0.245283 C32 [0.22,0.3] [1,1] Weights 0.821693 0.178307 Table 4: The interval approximation options concerning the sub-criteria of environmental criterion sub-criteria GWP ETP LU Alternatives A 0.090862 0.041578 0.173079 B 0.026054 0.024023 0.030116 C 0.195402 0.180174 0.223084 D 0.036345 0.027719 0.042567 5 E 0.651339 0.726506 0.531153 Table 5 The interval approximation options concerning the sub-criteria of social and economic criteria sub-criteria H&S regulation turnover gain Alternatives A 0.037196 0.047475 0.224165 0.322223 B 0.109401 0.045455 0.044833 0.305145 C 0.164101 0.318182 0.336247 0.159262 D 0.492303 0.070707 0.058508 0.168588 E 0.197 0.318182 0.336247 0.044782 The results of ranking alternatives were shown in table 6. Alternative E is assigned as the most preferred choice with a weight of 0.594161, followed by alternative C with a value of 0.198146, alternative A with a value of 0.090549, alternative D with a value of 0.070878 and alternative B with a value of 0.036346. Table 6: The results of ranking the aluminum waste management system options alternatives A B C D E Ranking order Final obtained Weights 0.090549 0.036346 0.198146 0.070878 0.594161 E˃C˃A˃D˃B Rank of alternatives 3 5 2 4 1 5. Comparison with other existing methods The fuzzy AHP methods in the literature were compared (Büyüközkan et al., 2004, Ayağ and Özdemir, 2006) in table 7. There are important differences in their theoretical structures. The comparison includes advantages and disadvantages of each method. Main characteristics and advantages proposed method were referred at the bottom of table 8 and were denoted with the gray color. In addition, for evaluating proposed method, we applied Chang’s method(Chang, 1996) in order to assess the aluminum waste management systems. The obtained results show that the ranking of the alternatives in two methods are similar (See table 8). Table 7: The comparison of various fuzzy AHP methods (Büyüközkan et al., 2004) (Ayağ and Özdemir, 2006) Sources Main characteristics Advantages (A)/Disadvantages (D) Van Direct extension of Saaty’s AHP method with (A) The opinions of multiple decision-makers can be Laarhove triangular fuzzy numbers modeled in the reciprocal matrix n Lootsma’s logarithmic least square method is used to (D) There is not always a solution to the linear and derive fuzzy weights and fuzzy performance scores equations Pedrycz (D) The computational requirement is tremendous, (1983) even for a small problem (D) It allows only triangular fuzzy numbers to be used Buckley Direct extension of Saaty’s AHP method with (A) It is easy to extend to the fuzzy case (1985) trapezoidal fuzzy numbeds Uses the geometric mean method to derive fuzzy (A) It guarantees an unique solution to the reciprocal weights and performance scores comparison matrix (D) The computational requirement is tremendous Boender Modifies van Laarhoven and pedrycz’s method (A) The opinions of multiple decision-makers can et be modeled al.(1989) Presents a more robust approach to the normalization (D) The computational requirement is tremendous 6 of the local priorities Synthetical degree values Chang (1996) (A) The computational requirement is relatively low (A) It follows the steps of crisp AHP. It does not involve additional operation (D) It allows only triangular fuzzy numbers to be used Layer simple sequencing Composite total sequencing Cheng (1996) Proposed method Builds fuzzy standards Represents performance scores by membership functions (A) The computational requirement is not tremendous (D) Entropy is used when probability distribution is known. The method is based on both probability and possibility measures Uses entropy concepts to calculate aggregate weights Uses interval approximation to defuzzfication (A) It allows all fuzzy numbers to be used (A) It keeps uncertainty of fuzzy number in itself Uses goal programming procedure to obtain weights (A)It is easy to do, especially, with a software such as Lingo Table 8: The comparison of results of proposed method and Chang’ fuzzy AHP method Alternatives Weights (proposed) A 0.090549 B 0.036346 C 0.198146 D 0.070878 E 0.5941 Ranking order (the proposed method) Ranking order (Chang’s method) Rank of alternatives 3 5 2 4 1 Weights (Cang’s method) 0.094855 0.006343 0.305851 0.01511 0.409039 E˃C˃A˃D˃B E˃C˃A˃D˃B Rank of alternatives 3 5 2 4 1 6. Discussion: Over 200 Kg of aluminum black dross as waste are produced for each ton of secondary aluminum. Black dross is either duplicate recovered as by-products or landfilled. However, releasing this quantity in environment can produce considerable negative consequences from air, water and soil pollution point of view. The presented model for industrial waste management alternatives was implemented in the case of aluminum waste systems in the industrial city of Arak. 6.1 proposed method The life-cycle thinking is a unique way of addressing environmental problems from a system perspective. In addition, no single solution is available as each industry in each country has different characteristics in terms of geographical environmental as well as social and economic aspects. Several management decisions are required to provide efficient aluminum waste management systems. The aim of this paper is proposing a method for application fuzzy AHP in aluminum waste management system. This model, which integrates social, economic and environmental aspects, is a fuzzy multiple-criteria decision-making problem. It can systematically evaluate and contains interdependency relationship among criteria under uncertainty. The results of the present study illustrates that the procedure is simple in calculations and set priorities. For the proposed integrated fuzzy AHP model, five alternatives are investigated. In this study we applied the NWIA-of-FNs to convert each fuzzy element of the pairwise comparison matrix to an interval. Then, we applied goal programming model for driving the weights and LINGO11 to solve the problems. In the present study, we apply environmental, social and economic criteria to evaluate and support decision-making within the aluminum industry as a MCDM problem. On the other hand, the fuzzy AHP used not only as a way to handle the inner dependences within a set of aspects and criteria, but 7 also as a way of producing more valuable information for decision making. We have considered seven sub-criteria from a group of three main criteria, namely: environmental, social and economic. Firstly, the decision makers evaluated each waste management alternative for the selected criteria and sub-criteria. Secondly, these evaluation results take into account the weight of each criteria and sub-criteria. Also we have transformed the collected data into fuzzy version. Finally, a real MCDM problem has been applied for the proposed decision making method which aims to rank the aluminum waste management system alternatives. According to the results of the expert judgment, the most influential environmental subcriteria are determined as global warming potential (GWP), human toxicity potential (HTP) and land use (LU). On the other hand, the most important social indicator is indicated as Health and Safety at work (H&S) and regulation (Reg.) and the most influential economic sub-criteria are determined as turnover and gain. As each of the presented alternatives represents a hypothetical scenario, any preference obtained and rank calculated will be under those circumstances for the case of the impacts and the participation of each decision makers. 6.2 Fuzzy AHP and LCA The primary response collected from our involved Group Decision making showed that they felt difficulty in linking environmental sub-criteria and proposed aluminum recycling process. Therefore, we used SimaPro LCA software (www.pre-sustainability.com/simapro) to generate quantitative information. The primary LCA results incorporate into the decision making process as a guide by experts group. 6.3 Comparing the five aluminum waste management alternatives: Table 6 shows that alternative E has the highest ranking compared to other alternatives. Also the alternative C and alternative A are ranked the third and fourth, respectively. Apart from these three alternatives, the other alternatives of the aluminum waste management system like alternative D and alternative B, ranked the fourth and fifth. Each alternative presents a solution for the aluminum waste management system with a certain degree of trade-off between benefit and its consequences related to the environmental, social and economic aspects. For example, the selection choice of alternative C could be increased by increasing amount of new aluminum scraps related to the primary aluminum production process. Also, the alternative D represents the export of aluminum waste to other places in the form of aluminum black dross with less metallurgic aluminum. In this way, the environmental and social impacts related to the recycling process transit to other place with less commitment to reduce them. Table 4 shows that alternative B has the highest environmental impact with weight values 0.026054, 0.024023 and 0.030116 concerning global warming potential (GWP), human toxicity potential (HTP) and land use (LU), respectively. However, this is predictable because the beneficiation activities such as sorting are not accomplished and final waste is released in environment without regarding the legal requirements and regulations. In this case, alternative D with values 0.036345, 0.027719 and 0.042567 and alternative A with values 0.090862, 0.041578, 0.173079 are ranked the third and fourth, respectively. Also alternative E, generally, has the lowest impacts to all environmental sub-criteria compared to the other alternatives (See table 4). This is not surprising because the finished alloy is composed of the secondary aluminum (include aluminum scrap and aluminum dross) with 99.5% pure aluminum and the primary aluminum with grade 98% is known. In this option and also alternative C as the second preference, the beneficiation activities such as washing, separating and sorting are applied and aluminum black dross are duplicate recycled in plant, and as a result, the final waste is landfilled healthy. On the other hand, this comparison shows that alternative A has the highest score for gain as the economic subcriteria with a value equal to 0.322223. This trend may be, because of the importance of income rather than health, safety and with of the environmental consideration. In this alternative, weight score to health and safety as social sub-criteria is 0.109401. It has lowest value compared to the other alternatives. Regulation as other social sub-criteria has similar condition. Generally, observing regulations including health and safety and environmental requirements increases costs and decreases incomes. Also turnover 8 as other economic sub criterion has a different situation and its scores are in opposite point of gain criterion. For example, as shown in table 5, the decision makers for alternative B concerning gain and turnover sub-criteria considered values 0.044833 and 0.305145, respectively. In this case, generally the small industries in Iran with less turn over and more gain have more environmental issues compared to the large industries. This case needs deep study. Alternatives that regard health and safety regulations at work and expose less accident and occupational diseases, have been found to be high ranked compared to the other alternatives. However, alternative D has the highest score to health and safety, though it is the fourth preference compared to the other alternatives in the point of the decision makers’ view. Also alternative C concerning health and safety with relatively low value 0.164101 is the third preference compared to the other alternatives. This result is surprising and should be analyzed deeply. This comparison shows that the alternatives which have the high health and safety levels as social subcriterion, do not necessarily have been found to be high ranked compared to the other options. 6.4 limitations and future research This model, also have disadvantages. For example, FAHP model uses aggregated categories data in which several subcategories are evaluated under the same main category. This will increase the uncertainty in FAHP that can be solved by using more specific life cycle data for several steps of aluminum waste. It is important to note that the weights of sub-criteria obtained from expert judgment are also subject to uncertainties. With changing weights, a Fuzzy MCDM decision making method might give different results for the ranking of aluminum waste management alternatives. From the application perspective, this research will provide a valuable insight for managers to make their attempts for improving the environmental, social and economic conditions, all together at the same time. 7. Conclusions: Until now slight attention has been given to the environmental aspects of processing output of aluminum dross and aluminum scrap as aluminum waste. This paper proposed a methodical and easy-to-use method for the proposed system selection as a MCDM problem. All the information collected was related to the literature, statistics, the primary LCA result, the written documents and findings from interviews. For the proposed integrated fuzzy AHP model, five alternatives are investigated. This study applied the NWIAof-FNs to convert each fuzzy element of the pairwise comparison matrix to an interval. Then, we applied the goal programming model for weighting and LINGO11 to solve the problems. The results showed that alternative E and alternative B are assigned as the best and the worst preferred choice with weights of 0.594161 and 0.036346, respectively. This comparison shows that alternative A has the highest score for gain with a value equal to 0.322223. Turnover as other economic sub-criterion has a different situation and its scores are in opposite point of the gain criterion. Alternative C concerning health and safety with relatively low value 0.164101 was the third preference compared to the other alternatives. This result was surprising and should be analyzed deeply. The proposed methodology can be utilized for similar problems where the multiple criteria are present. This study will provide a valuable insight for managers to make their attempts to improve the environmental, social and economic conditions all together at the same time. In future research, current fuzzy approach can be developed and applied for different MCDM problems in industry where the conflicting criteria exist. References: ABDI, M. 2009. Fuzzy multi-criteria decision model for evaluating reconfigurable machines. International Journal of Production Economics, 117, 1-15. AYAĞ, Z. & ÖZDEMIR, R. G. 2006. A fuzzy AHP approach to evaluating machine tool alternatives. Journal of Intelligent Manufacturing, 17, 179-190. 9 BÜYÜKÖZKAN, G., KAHRAMAN, C. & RUAN, D. 2004. A fuzzy multi-criteria decision approach for software development strategy selection. International Journal of General Systems, 33, 259-280. CHAN, F. T. & KUMAR, N. 2007. Global supplier development considering risk factors using fuzzy extended AHP-based approach. Omega, 35, 417-431. CHAN, H. K., WANG, X., WHITE, G. R. T. & YIP, N. 2013. An extended fuzzy-AHP approach for the evaluation of green product designs. Engineering Management, IEEE Transactions on, 60, 327339. CHANG, D.-Y. 1996. Applications of the extent analysis method on fuzzy AHP. European journal of operational research, 95, 649-655. HING KAI, C., XIAOJUN, W., WHITE, G. R. T. & YIP, N. 2013. An Extended Fuzzy-AHP Approach for the Evaluation of Green Product Designs. Engineering Management, IEEE Transactions on, 60, 327-339. HONG, J.-P., WANG, J., CHEN, H.-Y., SUN, B.-D., LI, J.-J. & CHEN, C. 2010. Process of aluminum dross recycling and life cycle assessment for Al-Si alloys and brown fused alumina. Transactions of Nonferrous Metals Society of China, 20, 2155-2161. IZADIKHAH, M. 2012. Deriving Weights of Criteria from Inconsistent Fuzzy Comparison Matrices by Using the Nearest Weighted Interval Approximation. Advances in Operations Research. doi:10.1155/2012/574710 LIN, C.-Y., LEE, A. H. & KANG, H.-Y. 2013. An integrated new product development framework–an application on green and low-carbon products. International Journal of Systems Science, 1-21. LIU, G., BANGS, C. E. & MULLER, D. B. 2013. Stock dynamics and emission pathways of the global aluminium cycle. Nature Clim. Change, 3, 338-342. LIU, G. & MÜLLER, D. B. 2012. Addressing sustainability in the aluminum industry: a critical review of life cycle assessments. Journal of Cleaner Production, 35, 108-117. NORGATE, T. & JAHANSHAHI, S. 2011. Reducing the greenhouse gas footprint of primary metal production: Where should the focus be? Minerals Engineering, 24, 1563-1570. SAATY, T. L. 1988. What is the analytic hierarchy process?, Springer. SHINZATO, M. C. & HYPOLITO, R. 2005. Solid waste from aluminum recycling process: characterization and reuse of its economically valuable constituents. Waste management, 25, 3746. TZENG, G.-H. & HUANG, J.-J. 2013. Fuzzy multiple objective decision making, CRC Press. VAN LAARHOVEN, P. & PEDRYCZ, W. 1983. A fuzzy extension of Saaty's priority theory. Fuzzy Sets and Systems, 11, 199-227. WANG, L., ZHANG, H. & ZENG, Y.-R. 2012. Fuzzy analytic hierarchy process (FAHP) and balanced scorecard approach for evaluating performance of Third-Party Logistics (TPL) enterprises in Chinese context. African Journal of Business Management, 6, 521-529. WECK, M., KLOCKE, F., SCHELL, H. & RÜENAUVER, E. 1997. Evaluating alternative production cycles using the extended fuzzy AHP method. European journal of operational research, 100, 351-366. WECKENMANN, A. & SCHWAN, A. 2001. Environmental life cycle assessment with support of fuzzysets. The International Journal of Life Cycle Assessment, 6, 13-18. ZADEH, L. A. 1965. Fuzzy sets. Information and control, 8, 338-353. ZHENG, G., JING, Y., HUANG, H. & GAO, Y. 2011. Applying LCA and fuzzy AHP to evaluate building energy conservation. Civil Engineering and Environmental Systems, 28, 123-141. 10