Rules for Contractors - LyondellBasell Industries

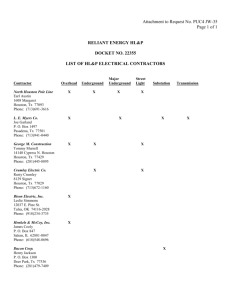

advertisement