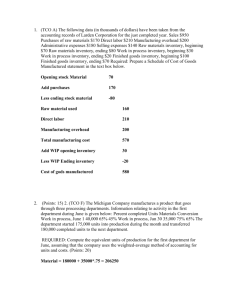

CHAPTER 2

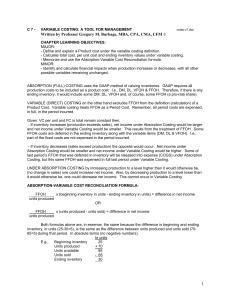

advertisement