10101001_10a00qcscorrectivepreventiveactionprocess

advertisement

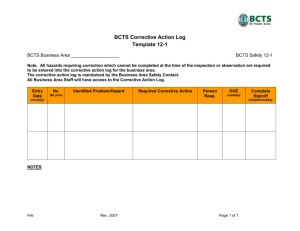

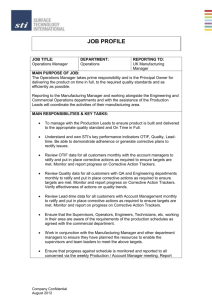

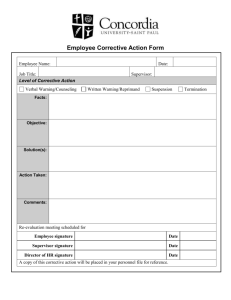

Quality System Work Instruction 10-10-1001: QCS – Corrective & Preventive Action Process rev-10a00 - Approved by: Quality Assurance, Operations 1.0 Purpose and Scope The purpose of this work instruction is to define the formal process of corrective and preventive actions associated with products, processes, and equipment. This document pertains to all departments whose activities have an impact on the company’s quality program. 1.1 Definitions C&P Action: Corrective and Preventive Action Case managed within QCS system CAP – Corrective Action Plan: An implementation plan created from the analysis of a problem and selection of the best solution. Plan may address a “quick-fix” to address immediate problem and/or a more detailed “root-cause” study, with a resolution to prevent reoccurrence of problem. CAM – Corrective Action Management Team: Permanent members assigned by the Company and include a Chairman from Quality, plus department leads from R&D, Quality, Operations, and Maintenance. CAT – Corrective Action Team: Team assigned to work a Corrective Action Case MRT – Management Review Team as defined by the company’s quality program. Priority High – Safety, Quality Concern (defective product, unusable production equipment) Priority Medium – Productivity, Value Added (Time or Dollar savings) Priority Low – Not system critical, low time or money savings. QCS – Quality Compliance System: Online system to manage and report quality compliance 1.2 Discussion Distinction between a corrective and preventive action is that a corrective action deals with actual nonconformities and a preventive action deals with a potential nonconformity. The procedure for handling both types of actions is the same. Therefore, this document does not distinguish between the two types and refers to both as corrective actions. The company’s Executive Sponsor appoints & empowers a Corrective Action Team. Permanent members include a) Chairman from Quality, and b) Department Leads from key functional areas, such as R&D, Quality, Operations, and Maintenance. The Corrective Action Team assigns temporary members on a case-by-case basis, selecting individuals with expertise on the problem or solution of any individual case. 10-10-1001_10a00 UNCONTROLLED IF PRINTED page 1 of 6 Quality System Work Instruction 10-10-1001: QCS – Corrective & Preventive Action Process rev-10a00 - Approved by: Quality Assurance, Operations 2.0 Work Instructions 10.0 Corrective & Preventative Action Process for Product, Process, and Equipment Initiate Initiate Open Open Closed Closed 6 CAM Managed Closure & Reporting Quality History, Status & Trends Customer Complaint reject Supplier Problems Detected Problems Manage per Schedule 1 2 new C&P action Anyone Identify Problem Suggested Improvements Improvement Projects 3 CAT CAM approved Root plan Rank Cause --& with Assign resources Corrective Schedule Action Plan authority to Work Group Related Actions Manage per Schedule 4 5 CAT Implement Implement complete --per approved scope CAM: Corrective Action Managers CAT: Corrective Action Team members Out Brief CAT (auditor) Audit Results effectiveness Follow-up Actions (is-req’d) 10-88-1001-09b01 STEP RESPONSIBILITY ACTION Identify Problem problem or preventive action identified 1 Anyone a) Enter Required Information - Using QCS, select 10. Corrective & Preventive Actions / New Tab - Enter required information within section “Problem Identification” - Title: descriptive - Problem-description: may include suggested improvements - Affected-Area: company defined picklist - Type: product, process, or equipment - Reason: internal problem, internal preventive, customer complaint - Priority of initiator: HIGH(expedite), Med, low, or blank(tbd) - Status: Problem Identification b) Add Attachments for added clarification ( if any) c) Save 10-10-1001_10a00 UNCONTROLLED IF PRINTED page 2 of 6 Quality System Work Instruction 10-10-1001: QCS – Corrective & Preventive Action Process rev-10a00 - Approved by: Quality Assurance, Operations STEP RESPONSIBILITY ACTION Rank, Assign, Schedule Scheduling of Open C&P Actions a) Rank C&P Actions (status “Problem Identifications”) - Using QCS, select 10. Corrective & Preventive Actions / Open Tab - Select & review individual OPEN C&P Actions - Clarify & Update ‘problem identification’ data, contact initiator if req’d - Determine Severity / set priority o High, Medium, Low - Per definitions above - Go To 02b o Reject: No Action To Be Taken - Enter reason-for-rejection – field “Action Taken” - Set status to “reject” - Notify Initiator by email - Go To Step-06 o Others: - Blank (unranked backlog) - Go To 02b CAM 2 Corrective Action Management Team b) Schedule C&P Actions to-be-worked - Select 10. Corrective & Preventive Actions / Open Tab - Review ranked C&P Actions - Select C&P Action determined “ready-to-work” - Set Status to “Planning” - Update Corrective Action Plan (CAP) section; o identify CAP Leader, CAT, Completion Date, … - Commit resources (people, funds) to support plan c) Notify CAP Leader & CAT (if assigned) by email note: the CAP Leader may request additional CAT member where expertise of problem and/or resolution is required 10-10-1001_10a00 UNCONTROLLED IF PRINTED page 3 of 6 Quality System Work Instruction 10-10-1001: QCS – Corrective & Preventive Action Process rev-10a00 - Approved by: Quality Assurance, Operations STEP RESPONSIBILITY ACTION Planning Root Cause & Corrective Action Plan a) Review Assignments & Current Information - Using QCS, select 10. Corrective & Preventive Actions / Open Tab - Select assigned “planning” C&P Action - Review assignments, schedule, attachments & CAT findings b) Problem Analysis o Redefine Problem - Reviews “knowns” - Clarify Problem to be worked & document in QCS, field Problem Analysis ( section “Establish Corrective Action Plan”) o Determine “Root-Cause” - Goal: Eliminate Reoccurrence of Problem, Not patch symptom - Drill to determine multiple suspect causes - Review know data, to narrow list of causes - Identify additional data required to further narrow list - Gather additional data & analyze (repeat above if more data req’d) - Identify “Root Cause” / document in QCS/ field Root Cause, ( section “Establish Corrective Action Plan”) CAT 3 Correct Action Team hints: - typically multiple meetings - look at product, equipment, process, and people - more complex problems can require longer analysis cycle - expand team to include required skills & knowledge - look for similar corrective actions, possible shared resolution c) Recommend Actions - Determine one or more C&P Actions o Changes to process o Changes to equipment o Changes to written work instructions o Goal: prevent recurrence, else earlier detection & correction - document in QCS/ field Recommended Actions, ( section “Establish Corrective Action Plan” ) d) Present to CAM for approval - Present Recommended Actions & Reasons Why - CAM accepts or requests changes to recommended actions o If adjustments - Go To 02c (or 02b) o If approved, CAM identifies implementation schedule - CAT updates QCS to complete plan - Update schedule dates (section “Establish Corrective Action Plan”) - Set Status to “Implement” ( section “Problem Identification”) 10-10-1001_10a00 UNCONTROLLED IF PRINTED page 4 of 6 Quality System Work Instruction 10-10-1001: QCS – Corrective & Preventive Action Process rev-10a00 - Approved by: Quality Assurance, Operations STEP RESPONSIBILITY ACTION Implementation CAT 4 Correct Action Team a) Implement C&P Action as defined in QCS b) Document Progress: Update section “CAP Implementation” - field: Corrective Action Taken - field: Actual Implementation (completion date) - attachments: as req’d - field: Status – promote to “In-Audit” on completion Audit Results scheduled after implementation, when effectiveness of actions can be reviewed. AUDITOR 5 Typically From Corrective Action Team a) Audit – perform review of actions taken to determine if actions where effective, and if root-cause of problem has been addressed. b) Document Results: update Section “Audit Results” - field: Audit performed by, actual audit date - field: Root-cause eliminated (y/n), Audit Results & Recommendations - attachments: as req’d (supporting documents, data, analysis…) c) On Completion / Notify CAM Managed Closure & Reporting a) Manage Open C&P Action Schedule - monitor & respond to near-delinquent & late actions CAM 6 Correct Action Management b) Review Audit Results to Close C&P Actions - if Root Cause not eliminated then initiate additional C&P Actions, ref parent C&P Action in description c) Close C&P Action Case – set Status to “Complete” d) Standard QCS Compliance Reporting to support - day-to-day managed progress - management reviews - internal & external audits - trend reporting 10-10-1001_10a00 UNCONTROLLED IF PRINTED page 5 of 6 Quality System Work Instruction 10-10-1001: QCS – Corrective & Preventive Action Process rev-10a00 - Approved by: Quality Assurance, Operations 3.0 References 3.1 Normative References - The following reference contains provisions which through reference in this text, constitutes provisions of this document. References, which are subject to revision, should always be used in the most recent form. QSP 10.1 Corrective and Preventive Actions 3.2 Informative References - The following references are included as bibliographic information, which may contain material useful for execution of this document. References, which are subject to revision, should always be used in the most recent form. QSP QSP QSP QSP QSP QSP QSP 01.1 Management Review Meetings 03.1 Internal Quality Audits 05.1 Control of Quality Records 06.1 Process Control 07.1 ID and Traceability 08.1 Inspection and Testing 09.1 Control of Nonconformance WI 10-10-0001 QCS – Access to Online Compliance System WI 10-10-0101 QCS – Management Review WI 10-10-0301 QCS – Internal Audit Process WI 10-10-0901 QCS – Nonconforming Process 3.3 Documentation/Records - The implementation of this document requires the use of the below listed forms or reasonable facsimiles thereof and may result in records as so indicated in addition to retained completed forms. References, which are subject to revision, should always be used in the most recent form. QCS – Quality Compliance System 10-10-1001_10a00 UNCONTROLLED IF PRINTED page 6 of 6