Advantages of Activity Based Costing System

advertisement

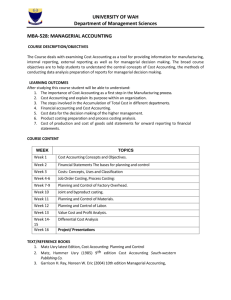

Activity based costing (ABC) ABC is a costing method that is designed to provide managers with cost information for strategic and other decisions that potentially affect capacity and therefore "fixed cost". It is used to determine product costs for special management reports. This system is ordinarily used as a supplement to the company's usual costing system. Most organizations that use ABC system have two costing systems--the official costing system that is used for preparing external financial reports and the activity based costing system that is used for internal decision making and for managing activities. In activity based costing: Non-manufacturing as well as manufacturing costs may be assigned to products. Some manufacturing costs may be excluded from product costs. A number of overhead cost pools are used, each of which is allocated to products and other costing objects using its own unique measure of activity. The allocation bases often differ from those used in traditional costing system. The overhead rates or activity rates may be based on the level of activity at capacity rather than on the budgeted level of activity. These differences from traditional cost accounting systems can dramatically impact the apparent costs of products and the profitability of products and customers. First, the initiative to implement activity based costing must be strongly supported by top management. Second, the design and implementation of activity based costing system should be the responsibility of a cross functional team rather than of the accounting department. The team should include representatives from each area that will use the data provided by the activity based costing system. Ordinarily, this would include representatives from marketing, production, engineering and top management as well as technically trained accounting staff. An outside consultant who specializes in activity based costing system serve as an advisor to the team. Implementation of activity based costing system must be initiated by top management due to two reasons. First, without leadership from top management, some managers may not see any reason to change. Second, if top managers do not support the ABC system and continue to play the game by the old rules, their subordinates will quickly get the message that ABC is not important and they will abandon the ABC initiative. Time after time, when accountants have attempted to implement an ABC system on their own with top-management support and active cooperation from other managers, the results have been ignored. For designing and implementing activity based costing system, management should carefully study the existing cost accounting system and review the articles in professionals and trade journals. The following chart explains the general structure of activity based (ABC) costing model. The Activity Based Costing Model Cost Objects (e.g., products and customers) Activities Consumption of Resources Cost Usually, company's traditional cost accounting system adequately measures the direct material and direct labor costs of products since these costs are directly traced to products. In most of the organizations activity based costing study is usually concerned solely with the other costs of the company - manufacturing overhead and selling, general, and administrative costs. The activity based costing implementation team should carefully plan about implementing activity based costing. Implementation process may be broken down into the following six basic steps. Steps for implementing activity based costing system: 1. Identify and define activities and activity cost pools. 2. Wherever possible, directly trace costs to activities and cost objects. 3. Assign costs to activity cost pools. 4. Calculate activity rates. 5. Assign costs to cost objects using the activity rates and activity measures. 6. Prepare management reports. The activity based costing systems, described by Robin Cooper and Robert Kaplan in the 1980's and 1990's, has attracted much attention. These systems identifies the major activities of a facility's production process and then classifies these activities into one of the following categories: Unit-level activities; Batch-level activities; Product-sustaining level activities Facility-sustaining level activities. The unit-level activities are performed each time a unit of a product is produced. The number of times unit-level activities (such as drilling holes and inspecting every part) are performed varies according to the number of units produced. The batch-level activities are performed each time a batch of goods is produced. The number of times batch-level activities (such as setting up a machine) are performed varies according to the number of batches made. The costs of these activities can be assigned to individual batches but they are fixed regardless of the number of units in the batch. Product-sustaining activities are performed as needed to support the production of each different type of product. Examples of product-sustaining activities are maintaining product specifications, performing engineering change notices and developing special testing routines. These costs can be assigned to individual products but are not proportional to the number of units or batches produced. Facility-sustaining activities support a facility's general manufacturing process. Examples of facility-sustaining activities are lighting and cleaning the facility, facility security and managing the facility. The costs of the unit-level, batch-level and product-sustaining level activities are attributed to products based on each product's consumption of those activities. The costs of facility-sustaining activities are allocated to products arbitrarily or treated as period costs. Ferris Corporation makes a single product - a fire resistant commercial filing cabinet - that it sells to office furniture distributors. The company has a simple ABC system that it uses for internal decision making. The company has two overhead departments whose costs are listed below: Manufacturing overhead Selling and administrative overhead $500,000 $300,000 Total overhead costs $800,000 The company's activity based costing system has the following activity cost pools and activity measures: Activity Cost Pool Assembling units Processing orders Supporting customers Other Activity Measures Number of units Number of orders Number of customers Not applicable Costs assigned to the "other" activity cost pool have no activity measure; they consist of the costs of unused capacity and organization-sustaining costs - neither of which are assigned to products, orders or customers. Ferris Corporation distributes the costs of manufacturing overhead and of selling and administrative overhead to the activity cost pools based on the feedback from employees interviewed, the results of which are reported below: Distribution of Resource Consumption Across Activity Cost Pools Assembling Processing Supporting Other Units Orders Customers Manufacturing overhead 50% 35% 5% 10% Selling and administrative overhead 10% 45% 25% 20% Total activity 1,000 units 250 orders 100 customers -- Total 100% 100% -- Required: 1. Perform the first stage allocation of overhead costs to the activity cost pools. 2. Compute activity rates for the activity cost pools. OfficeMart is one of the Ferris Corporation's customers. Last year OfficeMart ordered filing cabinets four different times. OfficeMart ordered a total of 80 cabinets during the year. Construct a table showing the overhead costs of these 80 units and four orders. Solution: 1. The first stage allocation of costs to the activity cost pools appears below: Activity Cost Pools Assembling Units Manufacturing overhead $250,000 Selling and admin. overhead 30,000 Total activity $280,000 Processing Orders $175,000 135,000 Supporting Customers $25,000 75,000 Other Total $50,000 60,000 $500,000 300,000 $310,000 $100,000 $110,000 $800,000 2. The activity rates for the activity cost pools are: Activity Cost Pools Assembling units Processing orders Supporting customers Total Cost $280,000 $310,000 $100,000 Total Activity 1,000 units 250 units 100 customers Activity Rate $280 per unit $1,240 per order $1,000 per customer 3. The overhead cost for the four orders of a total of 80 filing cabinets would be computed as follows: Activity Cost Pools Assembling units Processing orders Supporting customers Total Cost $280 per unit $1,240 per order $1000 per customer Total Activity 80 units 4 units Not applicable Activity Rate $22,400 $4,960 4. The product and customer margin can be computed as follows: Filing Cabinet Product Margin: Sales ($595 per unit × 80 units) Cost: Direct materials ($180 per unit × 80 units) Direct materials ($50 per unit × 80 units) Volume related overhead (above) Order related overhead (above) $47,600 $14,400 4,000 22,400 4,960 45,760 $1,840 ========== Customer Profitability Analysis - OfficeMart Product margin (above) Less: Customer support overhead (above) $1,840 1,000 $840 Advantages of Activity Based Costing System: Activity based costing system has the following main advantages / benefits: 1. More accurate costing of products/services, customers, distribution channels. 2. Better understanding overhead. 3. Easier to understand for everyone. 4. Utilizes unit cost rather than just total cost. 5. Integrates well with continuous improvement programs. 6. Makes visible waste and non-value added activities. 7. Supports performance management and scorecards 8. Enables costing of processes, supply chains, and value streams 9. Activity Based Costing mirrors way work is done 10. Facilitates benchmarking Disadvantages or Limitations of Activity Based Costing System: Activity based costing system help managers manage overhead and understand profitability of products and customers and therefore is a powerful tool for decision making. However activity based costing has a number of limitations or disadvantages. These limitations or disadvantages are briefly discussed below: 1. Implementing an ABC system is a major project that requires substantial resources. Once implemented an activity based costing system is costly to maintain. Data concerning numerous activity measures must be collected, checked, and entered into the system. 2. ABC produces numbers such as product margins, that are odds with the numbers produced by traditional costing systems. But managers are accustomed to using traditional costing systems to run their operations and traditional costing systems are often used in performance evaluations. 3. Activity based costing data can be easily misinterpreted and must be used with care when used in making decisions. Costs assigned to products, customers and other cost objects are only potentially relevant. Before making any significant decision using activity based costing data, managers must identify which costs are really relevant for the decisions at hand. 4. Reports generated by this system do not conform to generally accepted accounting principles (GAAP). Consequently, an organization involved in activity based costing should have two cost systems - one for internal use and one for preparing external reports.