Document

advertisement

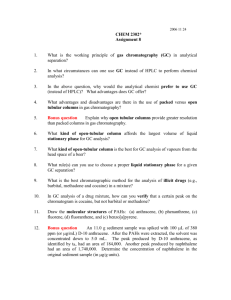

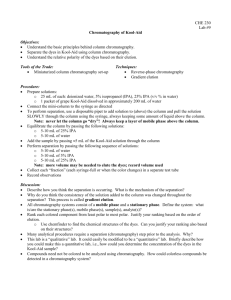

Separation Science Lecturer: Dr. S. D. M. Chinthaka Venue : C 1 lecture theater Time : Saturday 9.00 – 12.00 am References : Skoog and Leary: Principals of instrumental analysis, 6t dtion C.F. Poole, Essence of chromatography, 2nd edtion Separation Science Chromatography Most widely used analytical separation method Applications are grown to every branches of science First introduced by Russian botanist M.S. Tswatt (1903) Not an established method until 1930 Before 1930, Chemical separations were limited to crystallization, liquidliquid partitioning, and distillation Chromatography is essentially a physical method of separation in which the components to be separated are distributed between two phases One of these is stationary : (stationary phase) The other is moving in a definite direction (Mobile phase) Separation Science Important considerations Physical method of separation Two distinct phases are involved Separation results from differences in the distribution constants of the individual sample components between two phases Separations depend on a favorable contributions from thermodynamic and kinetic properties of the compounds to be separated Family Tree of chromatography Chromatography Supercritical fluid Gas Solid (GSC) Adsorption (LSC) Liquid (GLC) Size exclusion (SEC) Liquid Solid (SFC) Solid Ion exchange (IEC) Affinity (AC) Liquid (LLC) Micells (MEKC) Sorption (RPC) Sorption (CEC) Selective zone migration Transportation of solutes zones in column chromatography occurs entirely in the mobile phase Elution chromatography The mobile phase and stationary phase are normally at equilibrium Sample is applied to the column as a discrete band Mobile phase must compete with the stationary phase for the sample components The distribution constants for the sample components resulting the competition must be different The average rate that species migrate depends on the fraction of time it spend in mobile phase Most convenient method Zone migration Chromatogram The information obtained from a chromatographic experiments is contained in the chromatogram Information readily extracted from chromatograph Sample complexity (no of peaks) Qualitative identification of sample components (peak position) Quantitative assessment of the relative concentrations Physical properties of a solute in chromatographic systems (peak positions and profiles) Retention Partition coefficients Amobile Astationary cS K cM Retention time Detector signal tR tM Time Relationship between retention time and partition coefficient Average rate of analyte migration Average rate of mobile phase migration u 1 1 K Vs VM L tR u 1 1 1 t R t M 1 K Vs Vs = volume of stationary phase, VM = Volume of mobile phase L tM VM The rate of solute migration: capacity/retention factor ( kA’) k A K AVS VM tR tM k A tM If the capacity factor is less than unity, elution is so rapid and determination of retention time is difficult When the capacity factor Is larger, elution time becomes longer Separations are performed under conditions in which capacity factor for a given analyte in the mixture lie in the range 1 to 5,10 Selectivity factor () For species A and B KB KA k B k A t R B t M t R A t M Plate theory column efficiency Chromatographic peaks are generally Gaussian in shape During migration analyte particles undergo thousands of transfers between the stationary phase and mobile phase Sometimes residence time is transitory or longer period Particles are eluted during residence in the mobile phase Methods describing column efficiency- Plate theory Plate height (H) and number of theoretical plates (N) The smaller the plate height, the greater the column efficiency The higher the number of theoretical plates, the greater the column efficiency 2 LW H 16t R2 tR N 16 W 2 t N 5.54 R W1 2 2 van Deemter plot A Column resolution Provides a quantitative measure of its ability to separate two analytes 2t R B t R A Rs W A WB Column resolution 4% overlap 0.3% overlap The resolution of given stationary phase can be improved by lengthening the column : increasing number of plates Increase the time required for separation Effect of capacity factor on resolution and elution time General elution problem Solution for the general elution problem Change of the conditions that determine the values of k’ as separations proceeds For LC: variations in the composition of mobile phase (gradient elution) For GC: Temperature programming General elution problem General elution problem The function of GC To provide conditions required by column for achieving a separation without adversely effecting its performance Operation of the column requires A regulated flow of carrier gas An Inlet system to vaporize and mix the sample with the carrier gas A Thermostated oven to optimize the temperature for separation An online detector to monitor the separation Associated electronic components to control and to monitor instrument conditions and to record, manipulate, and format the chromatographic data Instrumentation Gas chromatography Pneumatic system of GC Sample inlet system Sample inlet Vaporize the sample and mixed with carrier gas prior to the start of the separation This is achieved Without reduction of the separation potential of the column In the absence of thermal degradation, adsorption or rearrangement of sample components Without discriminating of sample components by boiling point, polarity, or molecular weight Changes in column operating conditions should not affect the sampling processes Types of injectors used in GC Flash vaporization injectors Hot split/splitless injectors On column injections Flash vaporization injectors Injector must have sufficient thermal mass Carrier gas must be pre heated to avoid condensation Temperature range 25- 400 °C Generally sets 50 °C higher than maximum column temperature Because of high temperature, septum bleed must be avoided Use of low bleed septa Use of septum purge devices Flash vaporization injector Hot split/splitless injector Hot split/splitless injectors Allows injection of mixtures virtually independent of the choice of solvent Reduce band broadening Sample is isothermally evaporated and mixed with carrier gas Divide the sample into two streams of different flow Chamber is constructed from stainless steal tube lined with removable glass liner Injection volume is 0.2 to 2 μL with split ration 1:10 to 1: 1000 Split ratio depends on Sample volatility range, solvent, injected volume, injector temperature Splitless injection More suitable for quantitative analyses of trace compounds in dirty sample Volume of the chamber must be large enough to hold the entire sample Cold trapping is needed to refocus the sample Method allows the analysis of dilute samples without preconcentration Reduces solute discrimination Problems with hot vaporizing injectors Contamination by nonvolatile residues Nonvolatile droplets slowly release certain solute components to clean samples Degradation of sample components Detectors in GC Ideal detector Adequate sensitivity 10-8 10-15 g analyte/s Good stability and reproducibility Wide range of linear response (dynamic range) Temperature range RT- 400 °C Short response time that is independent of flow rate High reliability and easy use Universal response Nondestructive Detectors in GC Online detection of organic vapors Ionization, bulk physical property, optical and electrochemical detectors Based on the detector response Universal (flame ionization, thermal conductivity) Element selective (flame photometric, thermoionic ionization, and atomic emission detectors Structure selective (Electron capture, photoionization) Ionization detectors Flame ionization detector (FID) Thermoionic ionization detector (TID) Photoionization detector (PID) Electron capture detector (ECD) Helium ionization detector (HID) Each detector employs different method of ion production Detector operation is based on the fluctuation of an ion current in the presence of organic vapors Flame Ionization detector Background current 10-14A Increase to 10-12-10-5 A No response to He, Xe, H2 N2, N2O, NO, CO2, CS2, COS, NH3 , SO2 , and H2O and formic acid Flame Ionization detectors Produces nearly universal response to organic compounds Minimum sample detection limit is 10-13 g carbon/s: very low detection limit Long-term stability Simplicity of operation Fast signal response Exceptional liner response range: dynamic range is 106-107 Electron capture detector Electron capture detector The second most widely used ionization detector Good for the compounds with high electron affinity (pesticides, industrial chemicals, assessment of ozone depleting chemicals) Determination of drugs and hormones in bio fluids 63N β + M e + M+ (plasma) E + e EE- + M+ EM LC instrumentation LC instrumentation Favorable kinetic properties yield higher efficiency and shorter separation time in GC LC operates with modest number of theoretical plates at optimized selectivity achieved by appropriate selection of separation mode , stationary phase , mobile phase composition LSC : interfacial adsorption SEC : restricted permeability of porous solids LLC/BPC : Partition IEC : Electrostatic interactions AC : Structure specific binding Instrumental aspect of LC Operation conditions Must be capable of operating at very high pressure Accurate preparation of mobile phase composition Requires stable mobile phase flow Online detection with small operation volume Requires desired mobile phase composition to the head of the column as continuous and pulse free stream at known pressure and volumetric flow rates Sample injection requires insertion of known volume of sample into fully pressurized mobile phase flow Solvent reservoir Container resistant to chemical attack by mobile phase 2 μm filter is required for particle separation Degassing is required to prevent gas bubble formation when two solvents are mixed O2 must be removed to increase sensitivity and increase baseline separation Applying vacuum Ultrasonic treatments Helium spraying LC pumps Constant pressure pumps : pneumatic amplifier pumps Constant volume pumps : Syringe pumps Reciprocating piston pumps Syringe pump Pulse free output Very high pressure can be obtained Gradient and flow programming are possible Finite time is required for achieving constant volumetric flow rate Limited solvent reservoir capacity Pumps Reciprocating piston pumps Displaces a small volume (10- 400 μL) Made with material that can withstand high pressure and resistant to chemical attack Suitable for use at 5000 p.s.i Output flow is unstable Uses single piston with asymmetric cam Dual head reciprocating pump Composition gradients Achieved by mixing two or more solvents either incrementally or continuously Low pressure mixing Little influence by compressibility effects Eliminates thermodynamic volume change error Air bubble formation is avoided High pressure mixing Solvent compressibility and thermodynamic volume change influence the composition Needs separate pumps for each solvents LC Sample inlet system LC Sample inlet system Introduction of sample into highly pressurized mobile phase as a sharp plug Use external sample loop method Materials must be inert and non sorptive to avoid memory effect Leak tight to 7-10,000 p.s.i at RT Sample loop size is 5 μl- 5 mL Loop must filled completely/partially Sample must be prepared in same solvent as mobile phase or in weaker solvent but miscible with mobile phase Sample inlet system Sample inlet system Sample inlet system Detectors in LC No universal detectors for LC Should have minimal internal volume Two types of detectors are available Bulk property detectors: response to mobile phase bulk property e.g., refractive index, dielectric constant, density Solute property detectors: response to some property of solute e.g., UV absorbance, fluorescence, diffusion current Z shaped flow cell 1-10 μL volume 2- 10 mm in length Minimizes stagnant flow regions Reduce peak tailing Low volume fiber optic cell Diode array detectors Fluorescence detectors Columns in Chromatography Selection of mobile phases Non solvating gases are ideal for GC H2, He, N2 Behave almost ideally at low pressures and typically high GC temperatures Do not influence the selectivity No competition with solute molecules for stationary phase Flow rate influence the diffusion rate of the solute Cost, purity, safety, reactivity, and detector compatibility must be considered Choice of carrier gas vs plate height Columns in Chromatography Types of columns in GC Classical packed columns ( 2 mm id, 100-200m particles) Micropacked columns ( 1 mm id, 100-200m particles) Support coated open tubular columns (SCOT) Porous Layer open tubular columns (PLOT) Wall-Coated open tabular columns (WCOT) Stationary phases in GC Liquid must be unreactive Low vapor pressure Good coating characteristics Reasonable solubility in common organic solvents Must have wide temperature operating range (-60 - 400°C) Hydrocarbon, ether and ester stationary phases T/ °C Hexadecane 20- 50 Squlane 20-120 PPE-5 (polyphenyl ether) 20-200 EGS (polyethelene glycol succinate) 100-220 Carbowax 20M (poltethelene glycol) 60-225 Tetrabutylammonium tetrafluoroborate 162- 290 Poly siloxane stationary phases Most widely used in stationary phases in GC Wide temperature operating ranges Low vapor pressure Low temperature glass transition point Chemical inertness Good film forming property Easy of synthesis with wide range of chromatographic selectivity Easy of immobilization Some common polysiloxane stationary phases T/C° Dimethyl siloxane (OV-1) 100-350 Phenylmethyldimethylsoloxane (OV-7) 20-350 Tryfluoropropylmethylsiloxane (OV-210) 20-275 Cyanopropylphenylsiloxane (Silar 7CP) 50-250 Columns in LC Inorganic oxides and porous polymers with various surface functional groups used in early LC Chemically bonded phases almost completely replaces all the other materials Development of hydrophobic surfaces Allows use of polar mobile phase (water) : reverse phase liquid chromatography (RPC) RPC is the most widely used separation technique in LC because of life science applications Provides the separation of neutral, polar, and ionic samples of wide molecular weight ranges Column packing materials Porous inorganic materials Porous polymer materials 30-200 μm Porous/nonporous silica microparticals 0.1-10 μm Silica: granular and irregular Alumina, Titania and Zirconia Mechanically strong and hydrolytically stable Surface chemistry is more complex Chemically bonded inorganic oxides Organosiloxane-bonded phases Porous silica substrate modified by reaction with an organosilane reagents Monomeric synthesis Solution polymerization Deactivation of silanol groups