Features of gold having micrometer to centimeter dimensions can be

advertisement

Featuresof gold havingmicrometerto centimeterdimensions

can be formedthrougha combinationof stampingwith an elastomeric

stampand an alkanethiol"ink" followedby chemicaletching

Amit Kumarand GeorgeM. Whitesidesa)

02138

Haruord Uniuersity,Departmentof Chemistry,Cambridge,Massachusett.t

(Received16 February 1993;acceptedfor publication22 July 1993)

This letter describesa techniquethat can be used to produce well-definedfeaturesof gold' The

monolayer (SAM) on a gold substrateusing

technique involves patterning of a self-assembled

an elastomer stamp (fabricated either from a phenol-formaldehyde polymer or

followedby selectiveetchingin an aqueous,basicsolutionof cyanideion

polydimethylsiloxane),

(lM KOH, 0.1 M KCN). Electrically conductivestructuresof gold

dioxygen

and dissolved

small

as 1 pm have been produced using this procedure. Once a rubber

as

with dimensions

patterning

and etching of gold substratesis straightforward. This method is

stamp is fabricated,

convenient,does not require routine accessto clean rooms and photolithographic equipment,

and can be used to produce multiple copiesof a pattern.

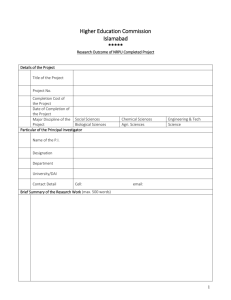

This report describesa simple method for the fabrication of patternsof gold, supportedon silicon substrates.A

monolayer

rubber stamp is usedto patterna self-assembled

(SAM) on a supportedgold film. The patternedsubstrate

is etchedin an aqueous,basic solution of cyanideion and

dissolveddioxygen.lr Featureshaving dimensionsas small

as I pm and as large as severalsquare cm have been produced through this technique.This processhas the advanthe desiredstampscan

tage of simplicity and convenience:

be fabricated either lithographically or nonlithographically, and once the stamp is available,multiple copiesof

the patterns can be formed using extremely straightforward experimentaltechniques.

The rubber stamps were made by two methods. Large

featureswere made using standardlithographicfabrication

proceduresavailableas commercialservices(Logan Stamp

Works, Boston, MA). The desired pattern was photographed, and a positive slide was used as a mask. The

output of a medium pressuremercur!' arc lamp was prol e cte d t hr ough t he s l i d e o n to a N o v o l a c re s i n (a phenol to rm aldehy depoly m e r. H e rc u l e s .Wi l mi n g to n , D E ). R egions that were exposed to the ultraviolet radiation

d i ssolv edin a m ild s o a p s o l u ti o n .T h e re ma i n i ng,unexposedpolymer was mounted on a basefor stamping.Features as small as 200 pm were produced using this relatively imprecisephotolithographicprocess.Currently, the

u p p e rlim it in s iz eis d i c ta te db y th e s i z eo f th e s ta mp that

can be produced (30 cm x 40 cm ) by the commercially

a va i lableM er r igr ap h l 2 l 6 P h o to p o l y m e rEx p o s ureU ni t

(He rc ules .W ilm ing to n , D E ).

I nk padsf or s t a m p i n gw e re p re p a re dh v m o i steni nga

pieceof lint-freepaper with a 0.1-l mM solution of hexadecanethiolin either ethanol or diethyl ether. It was inrportant to keep the ink pad as free of lint as possible.

solution was poured diAlternatively,the hexadecanethiol

rectly onto the stamp. Ink formulations using other solvents such as tolueneor iso-octaneproducedfeatureshaving poorer resolution. Afier inking and stamping, the

"'.A.uthor to whom corresDondence should be addressed

2002

substratewas immediatelyimmersedin the etch solution

describedpreviously'."

patternsformed using

Figure I depicts representative

The versatility

polymer.

resin

Novolac

stampsmade of the

evietching-is

by

of this procedure-stamping followed

features

that

dent from the range in size and detail of the

can be produced. Any feature having dimensions greater

than 200 pm can be photographed,prepared as a rubber

stamp using routinely available commercial services,and

reproducedin gold supportedon silicon.

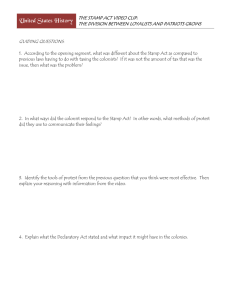

Stampsfor small (1-100 prm) featureswere fabricated

from polydimethylsiloxane(PDMS); Fig. 2 describesthe

process.The masters were made lithographically or were

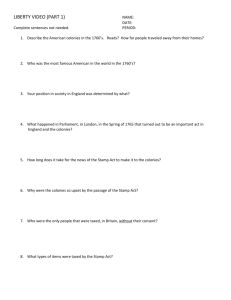

F I G . i . P h o t < t g r a p hos i l a r g e A u f e a t u r e sp r o d u c e d u s i n g t h e N o v o l a c

s t a m p s .( a ) - ( d ) C o m p l e x a n d s i m p l e f e a t u r e sc a n b e e a s i l vp r o d u c e d .

T h e s er e p r e s e n t a t i r lee a t u r e ss h o r vt h e d e g r e eo f i m p e r f e c t i o nt h a t r e s u l t s

from the use of commercialh rrreparedstamps.

. 1 9 9 3 0 0 0 3 - 6 9 5 1 / 9 3 / 6 34()1/ 2 0 0 2 / 3 / 5 6 . 0 0 c 1 9 9 3A m e r i c a nI n s t i t u t o

ef Physics

A p p l .P h y s .L e t t .6 3 ( 1 4 ) , 4O c t o b e r

2002

a)

a) 1' 2pm

+ $ h o tc re s i s tp a tte rn

tl-

I

Cold (50-200 nm)

supPorted on lO nrn

Ti adhesionliyer.

\

\

i

1

v

Arkanerhiol

Stamprngcnlo

golo substrate

-

<--

T h e t h r c k n e s so , t h e

a i k a n e t h i o l a t e ; a v p'rs

!-

rrrls,l

I e r . n i nisn

I cN-o.

I

f*a

ccmmercrallv available templates,such as transmrssron

electron microscopy grids. The template was placed in a

p l as t icpet r i dis h. A l 0 :1 (v :v ) mi x tu re o f PD M S-S yl gard

Silicone Elastomer 184 and Sylgard Curing Agent I 84

(Dow Corning Corp. Midland, MI) was poured into the

petri dish. It was not necessaryto put the mixture of

PDMS-elastomer and curing agent under vacuum to remove dissolveddioxygen. The PDMS cured at room temperature in the laboratory ambient for 30-60 min. This

'C

for approxcure was followed by additional curing at 65

imately I h or until the polymer was rigid. After cooling to

room temperature, the PDMS was carefully peeled from

the master.

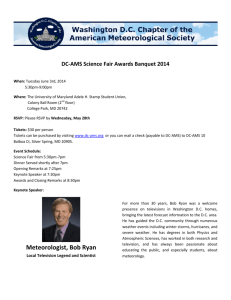

Figure 3 shows some representative scale features

formed using stamps made of PDMS. We have fabricated

severaltypes of features having dimensions ranging from I

pm to severalhundred pm. Figure 3(a) shows a fracture

profile of 2 pm wide lines of gold on silicon. Figure 3(b)

shows a microelectrode array. The gold microelectrodes

are2.5 pm wide. Figure 3(c) showsa regular array of gold

squareson silicon. The squaresare I 5 pm on a side. Such

arrays with squaresand rectangleshaving dimensionsfrom

l0 to 80 pm have been fabricated. The regularity of the

array was maintained over severalcentimeters.The micro2003

Appl.Phys.Lett.,Vol. 63, No. 14, 4 Octobell993

FIG. -1. SE micrographs of variclus t,\'pesi)f- teatures produced using

r u b b e r s t a m p i n ga n d c h e m i c a le t c h i n g .( a ) F r a c t u r e p r o f i l er t f a s e r i e so f

g o l d l i n e s s u p p o r t e do n a s i l i c o n w a f e r . T h c * r d t h o f t h e g o l d l i n e s i s 2

p m , a n d t h e t h i c k n e s so f t h e g o l d i s 2 0 0 0 A . ( b ) e l e c t r o d e s( 2 . 5 p m i n

w i d t h , s e p a r a t e db y 1 p m s p a c e s )i n a m i c r o e l e c t r o d ea r r a y ' .T h e c o n t a c t

p a d s a r e n o t v t s i b l e i n t h i s f r a m e a t t h i s m a g n i f i c a t i o n ,( c ) A r e g u l a r

array of squaresof gold supportedon silicon. The gold squaresare 15 pm

on a side. T'hesearrays exhibited such regularitl' txer several square

centimeters.

graphs in Fig. 3 illustrate that many types of featurescan

be produced using this technique.

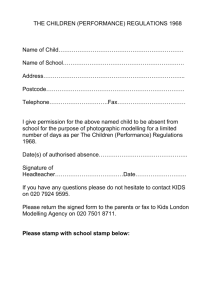

Figure 4 illustrates one method for increasingthe versatility of the stamping method. One stamp consisting of

parallel lines was usedto stamp the samepattern twice: for

the second pattern, the stamp was rotated through some

angle relative to the first. By multiple impressions,one

stamp can be used to produce several types of features.

This procedureis analogousto a procedure used in photolithography, where a photoresistis exposedmultiple times

through the same mask in different orientations.5

Rubber stamping followed by chemical etching, at its

current state,is a method for rapid prototyping of /rm-cm

scalefeatures.Lithography using rubber stamps has several advantagesover conventionallithographictechniques

A. Kumarand G. M. Whitesides

2003

:iN{

r,$ii

$*

N$

N$

WI

$i

ffii

$i

NNN

nl

$$l

$

N$

$

$

"$

$;

.si

$$$

"s,

,S,,

i'$,

i$,

;$

$$$ $$

is

;s

;: ss

ir)

Ln*

t

*il

ils

*

ilF*

*il

ilil*

**il***iln{}*

rrrr-rrtrrrlll

r-rtrlflrfftl

rr tt tlalrtlal

fllil

tlr

rllIl

! r a rf t-rll

rr trtllflllrr

rr-llllttll

rrt.fltlllll

rlu'lt*r$**'lrdi[

ltl

l'{'-'+i

5;

40 rirfi

FIG. 4. SE micrographsof featuresproduced through multiple stamping.

(a) These features were produced using a stamp consisting of parallel

l i n e so f 2 p r m w i d t h . T o o b t a i n t h e f e a t u r e si n ( b ) a n d ( c ) o n e s t a m p w a s

used to stamp the samepattern twice. To preparethe patterns in (b) and

( c ) t h e s t a m p i n ( a ) w a s u s e d t w i c e , w i t h t h e s e c o n di m p r e s s i o na t a n

a n g l e o f 4 5 ' ( b ) a n d 9 0 ' ( c ) r e l a t i v et o t h e f i r s t .

2004

and/or cl eanr oonls.

that requi reextensi vcrnstrLtmentati on

The primary advantageis the easewith which featurescan

be produced.Once a substratei s arai l abl e,a stampcan he

preparedfor use, and multiple impresslonscan be made

w i thout requi nngaddi ti onalphotol i thographl ' .

One of thc:probl emsu' i th thi s methodi s the relat ivelv

i neffi ci entmethodof del i very'of the thi ol to the surt aceol'

the substrate.S i nce the del i verr-of thi ol to the sur f ace

requiresphysicalcontact betweenthe stamp and the surface, some regionsbecomeblurred due to ihe unevenness

of the surfacetopology and due to mechanicalmovement

of the stamp during the stampingprocedure.Someregions

do not becomcderivatizedif contact is not made between

stamp and surface.Subsequentetching producesblurred

'Ihe

number densityof thesedefects.

featuresor etch pits.

however,is small enough that lines extendingseveralcm

are conductiveand parallel unconnectedlines are electrically isolated.

We havedemonstrateda lithographicmethodlbr rapid

prototyping of simple structureson a scalecomparableto

The method incorporatesthe useof

UV photolithography'.

a sel ecti vechemrculetch rn combi nati onw i th a technique

n' i th rr S A M on a mi cromcterscale.J'he

to patternsurti rces

p r i m a r r l d r a n t a s c o l ' t h r s m e t h o di s t h e e a s eo f p r e p a r a ti on of the stanrpand the desi redfeatures,and i ts c apabili ty for produci ng mul ti pl e copl esof the desi redpat t er n

w i th onl y one. i ni ti al l i thographi cstep.

This researchwas supportedin part by the Office of

Naval Research and the Defense Advanced Research

ProjectsAgency.

Appl. Phys.Lett.,Vol. 63, No. 14, 4 October.1993

' A . M . B r i t t a n .A n r S c i . 6 2 . 1 0 2 ( 1 9 1 4 ) .

r R . J . I ' u t l c i c p h u.r tI ' l r t ' C h e n r s t r ov J G t t l d( F . l s c v i e A

r . m s t e r d a m .1 9 7 8 ) .

. t r t l o n r r r r t (i i \ \ ' i l k r n r o r - t..l r l r u n c t ' dI n o r q u n i cC h e m i . s t y . 4 t he d .

I r . A ,C

( W i l e l. \ e n Y o r k . 1 ' ) l i O )

tA

Kunrar. l{ llrchrrrcka

. nd \. L. Abbott. J. Am. Chem.Soc.114,

9 1 8 8( t q q 2 )

'\.\'.

M Mcrreau, St'ntit'onductor Lithography: Principles. Practices and

t V o t e r i a l s( P l e n u m . N e w Y o r k . 1 9 8 8 ) .

A. Kumarand G. M. Whitesides

2004