CENTRAL SPARE PARTS WAREHOUSE FOR POWER PLANT

advertisement

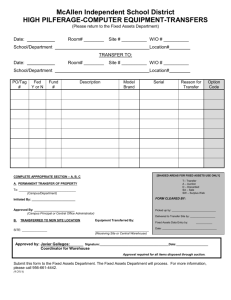

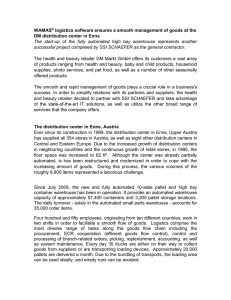

CS_Waertsilae-E2006 19.01.2006 9:32 Uhr Seite 2 No. 150105, © by SSI Schäfer Noell. Printed in Germany. Errors and omissions excepted. Translation: Manuela Ellebruch CENTRAL SPARE PARTS WAREHOUSE FOR POWER PLANT AND VESSEL ENGINES Case Study Wärtsilä Nederland B.V., Zwolle (NL) CS_Waertsilae-E2006 19.01.2006 9:32 Uhr Seite 3 PROJECT WÄRTSILÄ, ZWOLLE Project objective 왘 Savings on warehousing costs and personnel 왘 Improved reaction times during peak periods 왘 Increase in delivery quality 왘 Reduction of transport costs 왘 Centralization of distribution and deliveries 왘 High availability of items 왘 Automation of the flow of goods 왘 Error reduction 왘Shorter delivery times Infeed trays Our scope of supply and services: 왘Preparation of the logistics concept 왘 Implementation plan 왘 PICKOMAT® 왘 Tray conveyor system 왘Storage and retrieval machines 왘 High bay warehouse and racking system 왘 Warehouse management and control system Shuttle vehicle Automatic tray storage LxWxH Loading aids Storage locations Weight Type of storage system (ATSS) 36 x 10 x 13.5 m trays 7,104 250 kg single-deep ATSS – storage and retrieval machine (SRM) Quantity SRM / aisles 2 Load-carrying device TGW-Spectra Traveling speed 180 m/min. Lifting speed 60 m/min. Throughput 60 trays/h with double cycle Tray conveyor system, components components belt, multiple-strand, and roller conveyors (total length: 20 m), scales, repacking tables, lifting tables with integrated roller conveyor, stacker machine, shuttle vehicles, infeed/discharge station Workstation CS_Waertsilae-E2006 19.01.2006 9:32 Uhr Seite 4 PROJECT WÄRTSILÄ, ZWOLLE Worldwide spare parts supply as a centralized storage logistics solution For one of the worldwide leading manufacturers of engines for power plants and vessels, SSI SCHÄFER implemented a warehouse concept, which required the integration of several thousand groups of items. From smallest gaskets and medium-sized spare parts to heavy pallet units, a reliable and time-saving access as well as a holistic item management had to be designed. Result is the grouping of four warehouses in the most confined space. The integration of an automatic tray storage system including storage and retrieval machines as well as a 13 meter high PICKOMAT® for the automatic storage of small parts were of crucial significance for the extraordinary saving of time. PICKOMAT® offers 1,000 m2 of storage capacity on a base area of only 22 m2. Thanks to the interaction with “ant”, the warehouse management system from SSI, every product arrives at its destination within 72 hours. From here, it is then shipped throughout the world. PICKOMAT®innen Warehouse management system Computer hardware IBM Netfinity Server Operating system Windows 2000 Database system Oracle 9.2.0.1 WMS software Functionalities Warehouse management Goods receiving/shipping Order-picking Material flow control PICKOMAT® PICKOMAT®inside PICKOMAT®workstation 19.01.2006 9:32 Uhr Seite 1 No. 150105, © by SSI Schäfer Noell. Printed in Germany. Errors and omissions excepted. Translation: Manuela Ellebruch CS_Waertsilae-E2006 General contracting Planning and consulting Warehouse management system Control systems Member of Steel structure / racking systems Storage and retrieval machines Conveyor systems Service and maintenance SSI Schäfer Noell GmbH Reg.-Nr.: 267103 QM i_Park Klingholz 18/19 D-97232 Giebelstadt Phone: +49/93 34/979-0 Fax: +49/93 34/979-100 www.ssi-schaefer-noell.com info@ssi-schaefer-noell.com