Modifying Controlled Deterioration for Evaluating Field Weathering

advertisement

Volume 41 Number 2

http://www.rdi.ku.ac.th

Kasetsart Journal : Natural Science April - June 2007 Volume 41 Number 2

April - June 2007

KASETSART JOURNAL

NATURAL SCIENCE

Kasetsart Journal

Application for Membership

(http://www.rdi.ku.ac.th)

Kasetsart Journal (Natural Science) is a peer-reviewed journal of

Kasetsart University (www.ku.ac.th) which publishes original research articles on

natural sciences and other topics dealing with current knowledge and advances in

technology. The Kasetsart Journal (Natural Science) is issued four times per year. Articles

from researchers worldwide are welcomed.

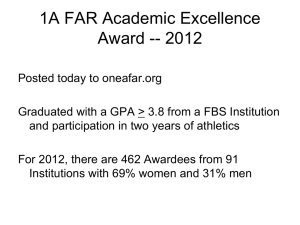

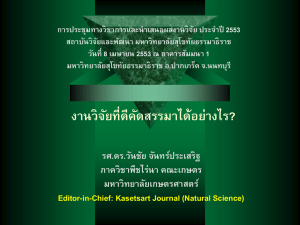

EDITORS

Editor-in-Chief

Wanchai Chanprasert

Associate Professor, Seed Science and Technology,

Faculty of Agriculture, Kasetsart University, Thailand

e-mail: agrwcc@ku.ac.th

Associate Editor

Amara Thongpan

Associate Professor, Cell and Molecular Biology,

Faculty of Science, Kasetsart University, Thailand

EDITORIAL BOARD

Roberto Bonoan

Researcher, Department Manager, Soil Science,

National Tobacco Administration, Department of

Agricualture, Philippines

Korchoke Chantawarangul

Assistant Professor, Civil Engineering, Faculty of

Engineering, Kasetsart University, Thailand

Parnjit Damrongkulkamjorn

Assistant Professor, Electrical Engineering, Faculty of

Engineering, Kasetsart University, Thailand

Praparat Hormchan

Associate Professor, Entomology, Faculty of

Agriculture, Kasetsart University, Thailand

Kanapol Jutamanee

Associate Professor, Plant Physiology, Faculty of

Science, Kasetsart University, Thailand

Onanong Naivikul

Professor, Cereal Chemistry and Technology, Faculty of

Agro-Industry, Kasetsart University, Thailand

Eiji Nawata

Associate Professor, Tropical Agriculture, Kyoto

University, Japan

Saran Petpiroon

Associate Professor, Marine Ecology and Pollution,

Faculty of Fisheries, Kasetsart University, Thailand

Witoon Prinyawiwatkul

Professor, Food Science and Technology, Louisiana State

University and LSU Agricultural Center, USA

Hathairat Rimkeeree

Assistant Professor, Product Development, Faculty of

Agro-Industry, Kasetsart University, Thailand

U Ravi Sangakkara

Professor, Crop Ecology, Faculty of Agriculture,

University of Peradeniya, Sri Lanka

Uthaiwan Sangwanit

Lecturer, Forest Resources, Faculty of Forestry,

Kasetsart University, Thailand

Thongchai Suwonsichon

Associate Professor, Food Science, Faculty of AgroIndustry, Kasetsart University, Thailand

Aree Thankijjanukij

Associate Library Director, Agricultural Information

Management, Kasetsart University

Satoru Tsuchikawa

Assistant Professor, Near Infrared Spectroscopy and

Agricultural Science, Graduate School of

Bioagricultural Sciences, Nagoya University, Japan

Sirichai Wongnarkpet

Assistant Professor, Veterinary Epidemiology, Faculty

of Veterinary Medicine, Kasetsart University, Thailand

Kenji Yamane

Associate Professor, Floriculture and Horticulture,

Faculty of Agriculture, Utsunomiya University, Japan

MANAGING EDITORS

Orawan Wongwanich

Senior Researcher, Kasetsart University Research and

Development Institute, Kasetsart University, Thailand

Somporn Maneeprasopsuk

Researcher, Kasetsart University Research and

Development Institute, Kasetsart University, Thailand

EDITORIAL ADVISORY BOARD

Gerald T. Baker

Professor, Entomology, Mississippi State University, USA

A. Bruce Bishop

Professor, Civil and Environmental Engineering, Utah State

University, USA

Samakkee Boonyawat

Associate Professor, Forest Resource Management, Faculty of

Forestry, Kasetsart University, Thailand

Delores Chambers

Assistant Professor, Food Science, College of Human Ecology,

Kansas State University, USA

Edgar Chambers

Professor, Food Science, College of Human Ecology, Kansas State

University, USA

Angsumarn Chandrapatya

Professor, Entomology, Faculty of Agriculture, Kasetsart University,

Thailand

Mauricio A. Elzo

Professor, Animal Breeding and Genetics, University of Florida,

USA

John Hampton

Professor, Seed Science and Technology, Lincoln University,

New Zealand

Parichat Hongsprabhas

Assistant Professor, Food Science, Faculty of Agro-Industry,

Kasetsart University, Thailand

Sathaporn Jittapalapong

Associate Professor, Veterinary Parasitology, Faculty of Veterinary

Medicine, Kasetsart University, Thailand

Helen H. Keenan

Professor, Environmental Science, University of Strathclyde,

Scotland

Saichol Ketsa

Professor, Postharvest Technology, Faculty of Agriculture,

Kasetsart University, Thailand

Jumras Limtrakul

Professor, Physical Chemistry, Faculty of Science, Kasetsart

University, Thailand

Chitochi Miki

Professor, Structural Engineering, Tokyo Institute of Technology,

Japan

Larry Miller

Professor, Agricultural Education College of Food, Agriculture and

Environment, Ohio State University, USA

Tadashi Miyata

Professor, Entomology, Nagoya University, Japan

Punpiti Piamsa-nga

Assistant Professor, Computer Engineering, Faculty of Engineering,

Kasetsart University, Thailand

Wiroj Rujopakarn

Professor, Transportation Engineering, Faculty of Engineering,

Kasetsart University, Thailand

Ed Sarobol

Associate Professor, Crop Physiology, Faculty of Agriculture,

Kasetsart University, Thailand

Narongrit Sombatsompop

Professor, Polymer Processing, School of Energy and Materials,

King Mongkut’s University of Technology Thonburi, Thailand

Peerasak Srinives

Professor, Plant Breeding, , Faculty of Agriculture at Kamphaeng

Saen, Kasetsart University, Thailand

Rungsit Suwanmankha

Professor, Weed Science, Faculty of Agriculture, Kasetsart

University, Thailand

Chanvit Vajrabukka

Professor, Animal Science, Physiology, Animal Behavior, Faculty

of Agriculture, Kasetsart University, Thailand

PUBLISHER

The Kasetsart Journal (Natural Science) is published by Kasetsart University Research

and Development Institute (KURDI), Kasetsart University, Bangkok, Thailand

EDITORIAL OFFICE

Kasetsart University Research and Development Institute (KURDI), Kasetsart

University, Chatuchak, Bangkok 10900, Thailand

TEL 66 (2) 5795548; FAX 66 (2) 5611474

e-mail: kj_rdi@ku.ac.th

Name : __________________________________________________________________

Title : __________________________________________________________________

Home Address : ____________________________________________________________

Tel : _________________________________ Fax : __________________________

Office Address : ____________________________________________________________

Tel : _________________________________ Fax : __________________________

E-mail Address : ____________________________________________________________

Type of application :

❑

❑

New Membership

Membership Extension

Membership type :

❑

❑

Regular (non – government) Membership

Student Membership

Submission information :

Student membership (Natural Science)

❑ Application and 60 bahts dues payment

❑ Letter of Recommendation from major advisor or the copy of student ID

Student membership (Social Science)

❑ Application and 40 bahts dues payment

❑ Letter of Recommendation from major advisor or the copy of student ID

Regular membership (Natural Science)

❑ Application and 120 bahts dues payment

Regular membership (Social Science)

❑ Application and 80 bahts dues payment

Send application materials to

Managing Editor of Kasetsart Journal

KURDI Kasetsart University

50 Paholyothin, Chatuchak, Bangkok 10900, Thailand

Tel. 66-2-5795548, 66-2-5611474, Fax. 66-2-5611474

e-mail: kj-rdi@ku.ac.th

Payment information :

❑ Cash

❑ Send money order made payable to KURDI , Kasetsart Post Office

Preferred address for mail

❑ Home

❑ Office

KASETSART JOURNAL

NATURAL SCIENCE

The publication of Kasetsart University

VOLUME 41

April - June 2007

NUMBER 2

Changing in TSS, TA and Sugar Contents and Sucrose Synthase Activity in Ethephon-Treated

‘Pattavia’ Pineapple Fruit

...................... Ngarmnij Chuenboonngarm, Niran Juntawong, Arunee Engkagul,

.............................................................. Wallop Arirob and Surin Peyachoknakul

Phylogenetic Analysis of Thai Amomum (Alpinioideae: Zingiberaceae) Using AFLP Markers

............. Wittaya Kaewsri, Yingyong Paisooksantivatana, Uamporn Veesommai,

............................................................. Wichan Eiadthong and Srunya Vajrodaya

Prediction of Sweet Corn Seeds Field Emergence under Wet Soil Condition

............................................ Vichai Wongvarodom and Wikanate Rangsikansong

Modifying Controlled Deterioration for Evaluating Field Weathering Resistance of Soybean

............................................. Ye Changrong, Prapa Sripichitt, Sunanta Juntakool,

.................................................................... Vipa Hongtrakul and Arom Sripichitt

Composite Line Method for the Development of Early Generation Hybrids

of Maize (Zea mays L.)

................. Nguyen Phuong, Krisda Samphantharak and Vatcharee Lertmongkol

Anther Culture of BC1F1 (KDML105//IRBB5/KDML105) Hybrid to Produce Bacterial Blight

Resistance Doubled Haploid Rice

................................. Supanyika Sengsai, Surin Peyachoknagul, Prapa Sripichitt,

.......................................................... Amara Thongpan and Pradit Pongtongkam

Novel PCR Primers for Specific Detection of Xanthomonas citri subsp. citri the Causal Agent

of Bacterial Citrus Canker

Udomsak Lertsuchatavanich, Ampaiwan Paradornuwat, Junlapark Chunwongse,

....................................................... Norman W. Schaad and Niphone Thaveechai

Soil-to-Plant Transfer of Radiocaesium in Thailand

................................................ Thitika Thammavech and Teerasak Veerapaspong

Beta-carotene, Mimosine and Quality of Leucaena Silage Kept at Different Duration

............................ Wanna Angthong, Boonlom Cheva-Isarakul, Somkid Promma

................................................................................ and Boonserm Cheva-Isarkul

Effects of Natural Mineral Soils on Body Weight and Liver Minerals of Black Head Somali

Sheep in Ethiopia

.................................... Sisay Tilahun, Pravee Vijchulata, Pornsri Chairatanayuth

.............................................................................. and Suwapong Swasdiphanich

Protoplast Isolation and Culture of Aquatic Plant Cryptocoryne wendtii De Wit

.................. Kanchanaree Pongchawee, Uthairat Na-Nakorn, Siranut Lamseejan,

.......................................................... Supawadee Poompuang and Salak Phansiri

205

213

227

232

242

251

262

274

282

288

300

Anti HSV-1 Activity of Spirulina platensis Polysaccharide

.... Nattayaporn Chirasuwan, Ratana Chaiklahan, Marasri Ruengjitchatchawalya

.......................................................... Boosya Bunnag and Morakot Tanticharoen

Taura Syndrome Virus Disease in Farm-Reared Penaeus monodon in Thailand

.................................................................... Chalor Limsuwan and Niti Chuchird

Optimization of Docosahexaenoic Acid (DHA) Production and Improvement of Astaxanthin

Content in a Mutant Schizochytrium limacinum Isolated from Mangrove Forest in Thailand

.................... Wassana Chatdumrong, Wichien Yongmanitchai, Savitree Limtong

...................................................................... and Wanchai Worawattanamateekul

Cloning, Expression, Purification and Biological Activities of Recombinant Mouse Interleukin-2

in E. coli M15

........... Sanchai Chantajorn, Ratchanee Hongprayoon and Thaweesak Songserm

Production and Partial Characterization of Chitosanases from a Newly Isolated Bacillus cereus

..... Sutee Wangtueai, Wanchai Worawattanamateekul, Mathana Sangjindavong,

.............................................. Nuanphan Naranong and Sarote Sirisansaneeyakul

Application of Pectin Coating in the Production of Vitamin Fortified Rice

..................................................... Lalita Chatiyanont and Phaisan Wuttijumnong

The effects of starter cultures on biogenic amine and free amino acid contents

in Nham during Fermentation

......... Sasithorn Limsuwan, Wonnop Visessanguan and Jirasak Kongkiattikajorn

Product Development System in Pattern Construction System, Standard Body Measurement

and Suitable Fitting Allowance for Thai Ladies Brand in Fashion Industry

................................................................................. Foengfurad Mungtavesinsuk

A Nonlinear Optimization Problem for Determining Safety Stocks in a Two-Stage

Manufacturing System

............................................................................................. Parthana Parthanadee

Design and Implementation of a Framework for .NET-based Utility Computing Infrastructure

............................................. Thanapol Rojanapanpat* and Putchong Uthayopas

311

319

324

335

346

356

373

380

394

Kasetsart J. (Nat. Sci.) 41 : 205 - 212 (2007)

Changing in TSS, TA and Sugar Contents and Sucrose Synthase

Activity in Ethephon-Treated ‘Pattavia’ Pineapple Fruit

Ngarmnij Chuenboonngarm1, Niran Juntawong2*, Arunee Engkagul3,

Wallop Arirob2 and Surin Peyachoknakul4

ABSTRACT

Exogenous ethylene increases endogenous ethylene which plays a crucial role on ripening in

climacteric fruits. Although pineapple is a non-climacteric fruit, ethylene released from ethephon is

effectively used to hasten the harvesting period. Effects from the use of a high concentration of ethephon

on eating quality, fruit size and the reduction in harvesting period have been reported. In this paper, the

effect of a low concentration of ethephon on pineapple fruit quality and sucrose synthase (SuSy) activity

was investigated. Field experiment was arranged in split plot design. In the main plot, two levels of

ethephon concentrations, i.e. 0 and 500 mg/l, were used by spraying at 110 days after forcing (DAF)

fruits. The sub plot was harvesting time, i.e. 5 times of one-week intervals from 124 to 152 DAF. We

found that the total soluble solid (TSS) was significantly increased in most of harvesting-treated fruits

while the titratable acid (TA) was significantly increased at 131 DAF of harvesting-treated fruits. Only

at 131 DAF harvesting time, the glucose content and SuSy activity of ethephon-treated fruits were

significantly reduced and return to the control level afterward. However, ethephon had no effect on the

fructose and sucrose contents at all harvesting times. In conclusion, fruit quality with shortening of

harvesting time could be improved by applying 500 mg/l ethephon at 110 DAF since TSS content which

is one of the parameter predicting eating quality of pineapple was increased without decreasing fruit

quality.

Key words: ‘Pattavia’ pineapple, ethephon, total soluble solid (TSS), titratable acidity (TA), sucrose

synthase

INTRODUCTION

Ethephon is one of the most effective

inflorescence forcing agents in pineapple [Ananas

comosus L. (Merr.)] that is widely used presently

(Bartholomew et al., 2003). Its function is to

stimulate the respiration rate of fruit while

1

2

3

4

*

chlorophyll remains in shell (Dull et al., 1967).

Moreover, it accelerates the ripening process and

concentrates the harvest peak (Chalermglin, 1979;

Smith, 1991). In other non-climacteric fruit such

as pepper, exogenous ethylene promotes and

increases a cellulase activity (Ferrarese et al.,

1995).

Bioscience Interdisciplinary Graduate Program, Faculty of Science, Kasetsart University, Bangkok 10900, Thailand.

Department of Botany, Faculty of Science, Kasetsart University, Bangkok 10900, Thailand.

Department of Biochemistry, Faculty of Science, Kasetsart University, Bangkok 10900, Thailand.

Department of Genetics, Faculty of Science, Kasetsart University, Bangkok 10900, Thailand.

Corresponding author, e-mail: fscinrj@ku.ac.th

Received date : 19/06/06

Accepted date : 06/10/06

206

Kasetsart J. (Nat. Sci.) 41(2)

To achieve the high fruit quality, high

total soluble solid (TSS) at the range of 12-14%

and relatively low titratable acidity (TA) of citric

acid at the range of 0.4-0.6% in pineapple flesh

are recommended for pineapple production in

Thailand (Thongtham, 1983). Though TSS and

TA are eating quality prediction parameters, TSS

is the only parameter suitable as a year-round index

(Bartolome et al., 1995). Bartolome et al. (1996)

found that TSS in pineapples was positively

correlated with total sugars. Beside reflecting fruit

quality, TA also indicates the sourness. In

pineapples, TA is reported as citric acid, not malic

acid. It varies primarily with fruit developmental

stages but does not relatively respond to short-term

environmental changes, while the malic acid varies

with environmental changes especially the light

(Singleton and Gortner, 1965).

Many factors including ethephon have

affected pineapple fruit quality (Bartholomew et

al., 2003). An application time and the quantity

of ethephon have influences on the quality of fruit.

Too early application causes the reduction in size

and weight of crown and fruit, whereas low TSS

and high TA contents are also found (Audinay,

1970; Chalermglin, 1979). TSS is highly

correlated with test-panel eating quality (Smith,

1988) and with total sugars (Bartoleme et al.,

1996). In pineapple fruits, fructose, sucrose, and

glucose play important roles in flavor

characteristics and are major sugars which vary

according to the stage of fruit development.

Sucrose content is lowest in the flesh during the

early stage of fruit growth but rapidly increases at

6 weeks before harvest and becomes predominant

in mature fruit. In the early stage, glucose is

slightly higher than fructose and remains relatively

constant through development while fructose

slightly increases at 2 weeks before harvest (Chen

and Paull, 2000). The changes in total sugar

contents are affected by the developmental stage

of fruits, climates, and varieties (Bartoleme et al.,

1996), nevertheless the change of each sugar

content in ethephon-treated pineapple fruits has

not been reported.

In a sink organ, sugar accumulation is

related to the presence of sucrose metabolizing

enzymes. One of them is sucrose synthase (SuSy)

(Taiz and Zeiger, 1998) which reversibly converts

sucrose and UDP to fructose and UDP-glucose.

SuSy is important in cell metabolism not only in

sink strength (Nguyen-Quoc and Foyer, 2001) but

also in cell wall synthesis (Nakai et al., 1999; Ruan

et al., 2003), and starch synthesis (D/Aoust et al.,

1999). Furthermore, it accumulates sucrose in

edible tissue of satsuma mandarin fruit (Komatsu

et al., 2002) and saves ATP in glycolysis pathway

(Huber and Azakawa, 1986). Chen and Paull

(2000) reported that in pineapple fruits SuSy

activity was higher at young stage, lower at 6

weeks before harvest, and then constant till

harvesting time. The change of SuSy activity in

ethephon treated fruit has also not been reported.

The objective of this work is to answer the question

if ethephon could increase TSS, TA, sugar content

and SuSy activity in pineapple fruit.

MATERIALS AND METHODS

Plant and fruit materials

Field-grown ‘Pattavia’ pineapple

[Ananas comosus L. (Merr.) cv. smooth cayenne]

planted at Sam Praya district, Petchburi Province,

Thailand, were used. Forcing of pineapple

inflorescence was done in the evening of

November 18, 2002, by spraying 50 ml of 250

mg/l ethephon (a.i. 48% w/v) including 3% (w/v)

urea on shoot. The experimental design used in

this study was split plot design. Main plot was

ethephon concentration of 0 and 500 mg/l by

spraying 50 ml volume per fruit at the age of 110

days after forcing (DAF). Pineapple fruit at this

age is pointed-eyes stage 3 according to the Dole

Company, Thailand, which is the last stage of

pointed-eyes pineapple (immature) and thereafter

the eyes will become flatted. Sub-plot was

Kasetsart J. (Nat. Sci.) 41(2)

harvesting time which started from 124 DAF until

152 DAF. Three replications, 8 fruits each, were

analyzed.

Fruit samples were brought to laboratory

and cut transversely into 3 sections after the size

and weight of crowns and fruits were measured.

Only the flesh of the middle section was used in

this study. A half of the flesh was crushed and the

juice was then used for determination of TSS and

TA. The other half, sliced into small pieces, was

used for the determination of the sugar content

and sucrose synthase activity. These sliced fleshes

of 8 fruits were pooled together as one of three

replications at each harvesting time. The tissues

were then frozen immediately in liquid nitrogen

and stored at -80°C until use.

Soluble sugar content

TSS was determined from extracted juice

using hand sugar refractometer. Soluble sugars in

the form of sucrose, fructose and glucose were

extracted following the method of Chen and Paull

(2000). After extraction, the solution was filtered

through a 0.45 mm filter, and 20 ml was injected

and analyzed with HPLC by using a Waters 2690

Separation Model instrumented with a Waters 410

Differential Refractometer detector, employing a

Sugar-PAK I (Waters Associates, Milford, USA)

column of stainless steel (300 mm length × 6.5

mm internal diameters). The eluting buffer was

0.1 mM calcium EDTA and the flow rate was 0.5

ml/min. Experiments were performed at 90°C.

Soluble sugars were quantified by comparing the

peak areas with external sucrose, glucose and

fructose standard solutions (Sigma Co., Ltd.).

Titratable acidity

TA was analyzed from extracted juice

after the determination of TSS contents and

reported as citric acid according to AOAC (1990).

Sucrose synthase determination

Sucrose synthase (SuSy) in frozen flesh

tissue was extracted as described by Chen and

207

Paull (2000). The extracted solution was desalted

by Hitrap Desalting column (Amersham

Biosciences) and 50 µl of desalted mixture was

used to determine the enzymatic activity in

synthesis direction according to the method of

Hubbard et al. (1989), as modified by Chen and

Paull (2000).

Statistical analysis

All data were analyzed the variance

(ANOVA) using statistical analysis software of

IRRISTAT version 93-3.

RESULTS AND DISCUSSION

The last harvesting time in this study

(152 DAF) was planned to coincide with

commercial harvesting time. The commercial

harvesting index for cannery fruit industry is

apparent when fruits reach full-size and the shell

color at the basal portion starts to change. The

effects of ethephon and harvesting time on fruit

quality, sugar content and SuSy activity after

treating at 110 DAF are shown in Table 1.

Ethephon concentration did not reduce the size and

weight of the crowns and fruits. The crowns and

fruits continued to develop after the treatment and

the crowns reached a full-size one week (138 DAF)

before the fruits did (145 DAF). Maximum growth

of the crowns indicated that the fruits were nearly

ready for harvest (Paull and Reyes, 1996). The

concentration of ethephon plays a significant role

in increasing the mean of TSS contents (11.02°

Brix) when compared with the mean of untreated

fruits (8.90°Brix). The mean of TA and sugar

contents including SuSy activity did not change,

compared with untreated fruits. The harvesting

time at 145 DAF provided the highest TA, TSS

and sucrose contents of 0.62% citric acid, 12.16°

Brix and 54.12 g/kg FW, respectively (P<0.01).

These indicated that the quality of fruit changes

during fruit development and TSS were related to

sucrose more than glucose and fructose as reported

Mean followed by the same letter within the same column are not significantly different at the 5% level according to LSD. Symbols * and ** indicate significance at the 0.05 and 0.01 levels

analyzed by DMRT, ns indicates no significant.

1/

TA = Tritratable acidity

2/

TSS = Total soluble solid

Table 1 Effects of ethephon concentrations and harvesting times on fruit quality, sugar content and sucrose synthase activity after treated at 110 days

after forcing (DAF).

Crown

Fruit

Flesh

Width Length Weight Width Length Weight

TA1/

TSS2/

Sucrose Glucose Fructose SuSy activity

_____(cm)_____

(g)

_____(cm)_____

(g)

(%citric (°Brix) ________(g/kg FW)________ (mmole/h/

acid)

g FW)

Ethephon

concentration

0 mg/l

12.6

12.6

140.8

11.0

14.0

882.4

0.54

8.90b

31.07

14.78

11.61

2.374

500 mg/l

11.6

11.1

127.1

11.3

14.1

922.9

0.59

11.02a

43.20

13.42

11.40

1.717

Harvesting time

124 DAF

11.4b

9.8b

124.8

11.5

14.2

846.2b

0.42c

8.08b

20.90d

14.46

10.86

2.297

131 DAF

11.3b

10.4b

114.4

10.7

13.4

760.4b

0.52b

8.78b

23.46cd

13.96

10.43

1.984

138 DAF

13.5a

13.4a

139.4

10.8

13.8

849.8b 0.58ab

8.48b

37.08bc

15.22

12.02

1.964

145 DAF

12.2ab

13.0a

143.3

11.8

15.0

1149.8a 0.62a

12.16a

54.12a

14.50

13.08

2.127

152 DAF

12.1ab

12.7a

147.9

11.1

13.8

906.7b

0.67a

12.30a 50.13ab

12.34

11.12

1.864

Ethephon

concentration

ns

ns

ns

ns

ns

ns

ns

*

ns

ns

ns

ns

Harvesting time

*

**

ns

ns

ns

**

**

**

**

ns

ns

ns

Ethephon

concentration X

ns

ns

ns

ns

ns

ns

*

*

ns

*

ns

*

Harvesting time

208

Kasetsart J. (Nat. Sci.) 41(2)

Kasetsart J. (Nat. Sci.) 41(2)

by Chen and Paull (2000). Figure 1 also showed

that sucrose content was low in immature fruit and

the highest content was achieved at 145 DAF while

glucose and fructose contents were relatively

constant during fruit growth as reported by Chen

and Paull (2000).

The interaction of ethephon

concentration with harvesting time significantly

affected TA, TSS and glucose contents at P<0.05

(Table 1). Comparing between the treatments of

ethephon concentration at 0 and 500 mg/l at each

harvesting time, it was found that almost all TSS

of treated fruits were significantly higher than

those of the control (Figure 2B). However only

treated fruits harvested at 131 DAF had TA content

higher (Figure 2A), but glucose content (Figure

2C) and SuSy activity were lower (Figure 2D) than

those of the untreated fruits. The high

concentration of TSS in harvested fruits treated at

131 DAF was affected by high TA rather than sugar

content because TSS does not represent only the

sugar content but also the contents of organic acids,

209

soluble pectins and other dissolved substances

which have different refractive indices from water

(Holcroft and Kader, 1999). This is the reason

why a direct measurement of sugar concentration

by HPLC is carried out. From our results (Figure

2A, 2B), ethephon affected the TA and glucose

contents of treated fruits in a few weeks after

ethephon application because ethephon is an

unstable substance which can be easily degraded

by high temperature and high pH in cytoplasm

(Bartholomew et al., 2003). Changing in TA and

glucose contents in pineapples may also be resulted

from a high respiration rate which is induced by

ethephon (Dull et al., 1967). This is due to the

use of glucose as a first glycolytic substance in a

respiratory pathway (Taiz and Zeiger, 1998) which

enhances organic acid contents (Ulrich, 1970).

High respiration rate also causes high oxygen

admission in tissue and this may be the other

reason for increasing TA.

It was also found that the TSS contents

of harvested fruits treated at 145 and 152 DAF

Figure 1 Sucrose, glucose and fructose contents in pineapple fruits after treated with 0 and 500 mg/l

ethephon at 110 days after forcing (DAF).

Kasetsart J. (Nat. Sci.) 41(2)

210

were higher than that of the untreated fruits (Figure

2B). The exogenous ethylene which was

suggested to increase the lipoxygenase activity by

Yu et al. (2003) might change the permeability of

the membrane and cause the increase of TSS in

these mature fruits. From the results on high TSS

(13.53°Brix) and TA (0.6% citric acid) contents

measured at 145 DAF, the treated fruits which are

in the range of high eating-quality fruit

(Bartholomew et al., 2003) could be harvested one

week earlier. Chalermglin (1979) also reported

that after applying 1,500 mg/l of ethephon at 112

DAF, the treated fruits could be harvested 11 days

18

0.9

a

0.8

a

a

a

0.4

0.3

b

a

a

b

6

0.2

4

0.1

2

0

a

10

8

b

a

12

b

a

b

14

TSS (°Brix)

TA (%citric acid)

16

a

a

a

0.6

a

a

a

0.7

0.5

earlier than those of the control. However, TA was

found to be inereased in treated fruits while fruit

size was reduced and TSS was unchanged. This

study indicates that the application of 500 mg/l

ethephon to 110 DAF fruits hastened the

harvesting time without reducing fruit quality.

Figure 2 also showed SuSy activities

which were affected by a significant interaction

between ethephon concentration and harvesting

time. When harvested at 131 DAF, the SuSy

activity of the treated fruits was significantly lower

than that of the untreated fruits. Chen and Paull

(2000) suggested that the low SuSy activity in

0

124

131

138

145

152 DAF

124

131

138

152 DAF

145

(B)

(A)

4

25

Glucose content (g/kg FW)

20

a

a

a

a

a a

a

a

15

b

10

5

SuSy Activity (µmole/h/g FV)

3.5

a

a

a

3

a

a

a

a

2.5

a

a

b

2

a

1.5

1

0.5

0

0

124

131

138

(C)

145

152 DAF

124

131

138

145

152 DAF

(D)

Figure 2 Changes in tritratable acidity (TA) (A), total soluble solid (TSS) (B) and glucose contents (C)

and sucrose synthase activity (D) in pineapple fruits flesh at various harvesting times after

treated with 500 mg/l ethephon ( ) and without ethephon ( ) at 110 days after forcing

(DAF). Error bars represent standard error of the means of three replications. Bars with the

same letter assigned are not significantly different at 0.05 probability level.

Kasetsart J. (Nat. Sci.) 41(2)

pineapple fruit allowed the accumulation of

sucrose. However, we found that the low SuSy

activity in harvested fruits treated at 131 did not

enhance the sucrose accumulation (no significant

interaction of sucrose was found, Table 1).

Therefore, the SuSy activity was not related to the

accumulation of sucrose in pineapples which is in

contrast to the activity in non-climacteric, satsuma

mandarin fruits (Komatsu et al., 2002). The

decrease of SuSy activity of harvested fruits treated

at 131 DAF might be resulted from the increase

in respiration rate which increases the amount of

ATP in cells. Therefore, SuSy activity which

involves in energy-saving pathway of glycolysis

(Huber and Akazawa, 1986) should be decreased.

SuSy is an important enzyme for synthesizing

UDP-glucose, the cellulose precursor (Nakai et al.,

1999). Thus, exogenous ethylene enhances a

cellulase activity (Ferrarese et al., 1995) which

leads to high production of UDP-glucose that may

act as a negative feedback to the SuSy activity.

The exact mechanisms of the SuSy activity as well

as the effect of ethylene on SuSy activity have still

not been well-defined.

CONCLUSION

We conclude that the ethephon at the rate

of 500 mg/l spraying at 110 DAF could increase

TSS in pineapple fruit, but not TA, sugar contents

and SuSy activity, and the treated fruits could be

harvested at 145 DAF without the decrease of fruit

size and weight.

ACKNOWLEDGEMENTS

The work was partially supported by

Thesis and Dissertation Support Fund, Graduate

School, Kasetsart University. Special thank to

Assoc. Prof. Dr. Napavarn Noparatnaraporn for

her suggestion in preparation of this manuscript.

211

LITERATURE CITED

AOAC. 1990. Official Methods of Analysis. Vol.

II, 15th ed., Association of Official Analytical

Chemists, Inc., Arlington, Virginia.

Audinay, A. 1970. Trial on the artificial control

of ripening of pineapples with ethrel. Fruits

25: 757.

Bartholomew D.P., E. Malezieux, G.M. Sanewski

and E. Sinclair. 2003. Inflorescence and fruit

development and yield, pp. 167-202. In D.P.

Bartholomew, R.E. Paull and K.G. Rohrbach

(eds.). The Pineapple: Botany, Production

and Uses. CABI Publishing, U.K.

Bartolome A.P., P. Ruperez and C. Fuster. 1995.

Pineapple fruit: morphological characteristic

chemical composition and sensory analysis of

Red Spanish and Smooth Cayenne cultivars.

Food Chemistry 53: 75-79.

Bartolome A.P., P. Ruperez and C. Fuster. 1996.

Changes in soluble sugars of two pineapple

fruit cultivars during frozen storage. Food

Chemistry 56: 163-166.

Chalermglin P. 1979. Effect of ethephon on

maturation and some fruit characteristics

of pineapple. MS dissertation. Kasetsart

University, Bangkok.

Chen, C.-C. and R.E. Paull. 2000. Sugar

metabolism and pineapple flesh translucency.

J. Amer. Soc. Hort. Sci. 125: 558-562.

/

D Aoust, M.-A., S. Yelle and B. Nguyen-Quoc.

1999. Antisense inhibition of tomato fruit

sucrose synthase decreases fruit setting and

the sucrose unloading capacity of young fruit.

Plant Cell 11: 2407-2418.

Dull, G.G., R.E. Young and J.B. Biale. 1967.

Respiratory patterns in fruit of pineapple,

Ananas comosus detached at different stages

of development. Physiol. Plant. 20: 10591065.

Ferrarese, L., L. Trainotti, P. Moretto, de L.P.

Polverino, N. Rascio and G. Casaeoro. 1995.

Differential ethylene-inducible expression of

212

Kasetsart J. (Nat. Sci.) 41(2)

cellulase in pepper plants. Plant Mol. Biol.

29: 735-747.

Holcroft, D.M. and A.A. Kader. 1999. Controlled

atmosphere-induced changes in pH and

organic acid metabolism may affect color of

stored strawberry fruit. Postharvest Biol.

Technol. 17: 19-32.

Hubbard, N.L., S.C. Huber and D.M. Pharr. 1989.

Sucrose phosphate synthase and acid invertase

as determinants of sucrose concentration in

developing muskmelon (Cucumis melo L.)

fruits. Plant Physiol. 91: 1527-1534.

Huber, S.C. and T. Akazawa. 1986. A novel

sucrose synthase pathway for sucrose

degradation in culture sycamore cells. Plant

Physiol. 81: 1008-1013.

Komatsu, A., T. Moriguchi, K. Koyame, M. Omura

and T. Akihama. 2002. Analysis of sucrose

synthase genes in citrus suggests different

roles and phylogenetic relationships. J. Exp.

Bot. 53: 61-71.

Nakai, T., N. Tonouchi, T. Konishi, Y. Kojima, T.

Tsuchida, F. Yoshinaga, F. Sakai and T.

Hayashi. 1999. Enhancement of cellulose

production by expression of sucrose synthase

in Acetobacter xylinum. PNAS 96: 14-18.

Nguyen-Quoc, B. and C.H. Foyer. 2001. A role

for ‘futile cycles’ involving invertase and

sucrose synthase in sucrose metabolism of

tomato fruit. J. Exp. Bot. 52: 881-889.

Ruan, Y.-L., D.J. Llewellyn and R.T. Furbank.

2003. Suppression of sucrose synthase gene

expression represses cotton fiber cell

initiation, elongation, and seed development.

Plant Cell 15: 952-964.

Singleton, V.L. and W.A. Gortner. 1965. Chemical

and physical development of pineapple fruit

II. Carbohydrate and acid constituents. J.

Food Sci. 30: 19-23.

Smith, L.G. 1988. Indices of physiological

maturity and eating quality in Smooth

Cayenne pineapples. 2. Indices of eating

quality. Queensl. J. Agric. Animal Sci. 45:

219-228.

. 1991. Effects of ethephon on ripening

and quality of freshmarket pineapples.

Austral. J. Exp. Agric. 31: 123-127.

Taiz, L. and E. Zeiger. 1998. Plant Physiology,

2nd ed., Sinaver Associates, Inc., Publishers,

Sunderland. 792 p.

Thongtham, J. 1983. Pineapple and Pineapple

Industry in Thailand. Kasetsart University

Press, Bangkok.

Ulrich, R. 1970. Organic acids, pp. 89-118. In

A.C. Hulme (ed.). The Biochemistry of

Fruits and Their Products, Vol 1. Academic

Press, London.

Yu, Z., C. Kun-Song, C. Qing-Jun, Z. Shang-Long

and R. Yi-Ping. 2003. Effects of

acetylsalicylic acid (ASA) and ethylene

treatments on ripening and softening of

postharvest kiwifruit. Acta Bot. Sinica 45:

1447-1452.

Kasetsart J. (Nat. Sci.) 41 : 213 - 226 (2007)

Phylogenetic Analysis of Thai Amomum (Alpinioideae: Zingiberaceae)

Using AFLP Markers

Wittaya Kaewsri1*, Yingyong Paisooksantivatana1 , Uamporn Veesommai1,

Wichan Eiadthong2 and Srunya Vajrodaya3

ABSTRACT

The AFLP technique was used to assess the genetic relationships among 45 zingiberaceous

plants including 40 collections of Amomum and 5 outgroup taxa: Alpinia, Etlingera 1, Etlingera 2,

Elettaria and Geostachys. Cluster analysis using unweighted pair group method with arithmetic mean

(UPGMA), based on AFLP data from 122 polymorphic bands generated with five primer combinations,

was performed. The grouping of accessions of most species corresponded with their fruit morphological

characteristics and were found to be consistent with previous studies. The species of Thai Amomum

were classified into 3 groups based on AFLP markers: A. aculeatum group, A. biflorum group, and A.

dealbatum group. The genetic relationships among genus Amomum and other genera in the tribe

Alpinioideae are still incompletely understood.

Key words: phylogenetic, Amomum, AFLP, Thailand

INTRODUCTION

Amomum Roxb. is one of the largest

genera in the ginger family (Zingiberaceae) with

about 150-180 species. As currently recognized,

Amomum occurs from the Himalayas through

Southeast Asia, Northern Australia and extends

into the central Pacific and is widely distributed

in Southeast Asia (Kiew, 1982; Smith, 1985).

Sirirugsa (2001) estimated about 15-20 species to

be found in Thailand. Plants of Amomum are

generally evergreen herbs inhabiting wet forests

in light gaps and at forest margins (Sakai and

Nagamasu, 1998). Many species are used as

medicine, spice, condiment and vegetable. Even

1

2

3

*

though the plants from this genus have been long

utilized, the identification is still confusing because

of the absence of a comprehensive work on the

genus and the much confused taxonomic problems.

These bring about many changes in their

taxonomic status.

Four species of Amomum were first

recognized by Linnaeus (1753) including: A.

cardamomum, A. zingiber, A. zerumbet and A.

grana-paradisi. These species have since been

transferred to Elettaria Maton, Zingiber Boehm

and Aframomum K. Schum. by Burtt and Smith

(1972). Baker (1892), classified Amomum into 5

sections; Geanthus, Achasma, Hornstedtia,

Euamomum and Cenolophon based on

Department of Horticulture, Faculty of Agriculture, Kasetsart University, Bangkok 10900, Thailand.

Department of Forest Biology, Faculty of Forestry, Kasetsart University, Bangkok 10900, Thailand.

Department of Botany, Faculty of Science, Kasetsart University, Bangkok 10900, Thailand.

Corresponding author, e-mail: wittayakaewsri@yahoo.com

Received date : 30/03/06

Accepted date : 3/10/06

214

Kasetsart J. (Nat. Sci.) 41(2)

morphological characteristics of spike, labellum

and anther crest. Schumann (1904) used the

characteristics of anther crest and classified

Amomum into 2 sections and 4 series. Section

Geanthus was divided into 2 series, series

Oliganthae and Polyanthae, distinguished by the

absence of an anther crest. Section Euamomum

was comprised of series Lobulatae and Integrae,

characterized by an anther crest. Gagnepain (1906)

separated Amomum into 3 groups based on the

characteristics of floral morphology such as anther

crest and lateral staminode. Loesener (1930)

classified Amomum into 2 main groups using

anther crest, Lobulatae and Integrae.

Xia et al. (2004) investigated the

phylogenetic status of Amomum using ITS and

matK DNA sequence data. They indicated that

Amomum as currently defined is polyphyletic with

three major groups of species (A. villosum Group,

A. tsao-ko Group and A. maximum Group) that do

not correspond with any previously recognized

sectional classification of the genus. They also

mentioned that some morphological characters

such as anther crest and fruit type could be useful

for classification.

The AFLP technique has been used to

study genetic diversity and phylogenetic

relationships in a wide range of plant species;

Lubberstedt et al. (2000) studied relationships

among early European maize inbreds, GarciaMass et al. (2000) used AFLP marker for

measuring genetic diversity in melon, Abdalla et

al. (2001) used AFLP marker for estimating

genetic relationships across a wide range of

taxonomic levels and for analyzing the

evolutionary and historical development of cotton

cultivars at the genomic level, Larson et al. (2001)

studied AFLP variation in agamospermous and

dioecious bluegrasses of western North America,

Mizumoto et al. (2003) used AFLP for studying

the diversity of nuclear and chloroplast genome

in wild einkorn wheat (Triticum urartu).

Because the relationships within genus

Amomum and other genera in tribe Alpinioideae

are still incompletely understood, a more detailed

analysis using other molecular techniques is

necessary. Knowledge of the genetic relationships

among them is essential to the classification of

the genus. This study was intended to determine

genetic relationships among species of the

Amomum genus occurring in Thailand using AFLP

markers.

MATERIALS AND METHODS

Plant materials

Forty accessions of Amomum and 5

accessions of outgroup taxa: Alpinia, Elettaria,

Etlingera 1, Etlingera 2 and Geostachys were used

in this study (Table 1). All plant materials were

grown and kept at Department of Horticulture,

Kasetsart University, Bangkok, Thailand.

DNA isolation and AFLP analysis

Total genomic DNAs were extracted

from 100 mg fresh young leaves using Qiagen

DNeasy Plant Mini kit (Qiagen GmbH, Hilden,

Germany).

AFLP analysis was performed following

the method of Vos et al. (1995) with minor

modifications. From each sample, 2 templates

were prepared by digesting 20-50 ng DNA with

the restriction enzyme combination EcoRI-MseI

and by ligating the corresponding oligonucleotide

adaptors in a total volume of 10 µl. Preselective

PCR amplification with primers corresponding to

adaptor core sequences (E+A and M+C) was

performed in a 10 µl reaction containing 3 µl of

AFLP template. PCR contained 10X PCR buffer,

0.5 µmol/L of each primer, 1 µmol/L of each dNTP,

and 1 U Taq DNA polymerase (Fermentas,

Lithuania) and was performed using a Biosystems

Mod. Gene Amp PCR system 9700 (Biosystems,

Montgomeryville, PA). PCR conditions consisted

of 1 cycle of 5 min at 50°C, 1 cycle of 3 min at

94°C, 24 cycles of 30 s at 94°C, 24 cycles of 1

Kasetsart J. (Nat. Sci.) 41(2)

215

Table 1 List of Thai Amomum accessions and outgroup taxa used in AFLP study.

Accessions

Species

Collected number

Collected places(provinces)

1

A. aculeatum Roxb.

Kaewsri-02

Kanchanaburi

2

A. biflorum Jack

Kaewsri-52

Chanthaburi

3

A. dealbatum Roxb.

Kaewsri-110

Chiang Mai

4

A. koenigii 1

Kaewsri-03

Kanchanaburi

5

A. koenigii 2

Kaewsri-29

Nakhon Nayok

6

A. micranthum Ridl.

Kaewsri-63

Chanthaburi

7

A. repoense Gagnep.

Kaewsri-64

Chanthaburi

8

A. rivale1*

Kaewsri-04

Kanchanaburi

9

A. rivale2*

Kaewsri-23

Kanchanaburi

10

A. cf. rivale

Kaewsri-33

Kanchanaburi

11

A. siamense Craib

Kaewsri-14

Tak

12

A. testaceum 1

Kaewsri-15

Tak (Cultivated)

13

A. testaceum 2

Kaewsri-16

Tak (Cultivated)

14

A. testaceum 3

Kaewsri-17

Tak (Cultivated)

15

A. testaceum 4

Kaewsri-96

Tak (Cultivated)

16

Amomum cf. testaceum

Kaewsri-86

Chumphon

17

A. uliginosum1

Kaewsri-30

Nakhon Nayok

18

A. uliginosum2

Kaewsri-92

Tak

19

A. uliginosum3

Kaewsri-32

Trat

20

A. cf. villosum1

Kaewsri-12

Tak (Cultivated)

21

A. cf. villosum2

Kaewsri-13

Tak

22

Amomum sp.1

Kaewsri-01

Kanchanaburi

23

Amomum sp.2

Kaewsri-10

Kanchanaburi

24

Amomum sp.3

Kaewsri-19

Prachuap Khiri Khan

25

Amomum sp.4

Kaewsri-22

Kanchanaburi

26

Amomum sp.5

Kaewsri-24

Kanchanaburi

27

Amomum sp.6a

Kaewsri-113

Chiang Mai

28

Amomum sp.6b

Kaewsri-88

Tak

29

Amomum sp.7

Kaewsri-27

Uthai Thani

30

Amomum sp.8

Kaewsri-35

Ranong

31

Amomum sp.9

Kaewsri-38

Ranong

32

Amomum sp.10

Kaewsri-50

Sakon Nakhon

33

Amomum sp.11

Kaewsri-68

Chumphon

34

Amomum sp.12

Kaewsri-70

Chumphon

35

Amomum sp.13

Kaewsri-81

Ranong

36

Amomum sp.14

Kaewsri-94

Tak

37

Amomum sp.15

Kaewsri-108

Chiang Mai

38

Amomum sp.16

Kaewsri-111

Chiang Mai

39

Amomum sp.17a

Kaewsri-134

Nan

40

Amomum sp.17b

Kaewsri-138

Nan

41

Alpinia nigra

Cultivated at KU

42

Elettaria cardamomum

Tak

43

Etlingera littoralis

Kanchanaburi

44

Etlingera pavieana

Chanthaburi

45

Geostachys sp.

Nakhon Nayok

The number 1, 2, 3 or 4 of each species = Amomum’s specimens that were collected from different places.

216

Kasetsart J. (Nat. Sci.) 41(2)

min at 56°C, and 24 cycles of 1 min at 72°C,

followed by an extension of 5 min at 72°C.

Amplification products were diluted in 100 µl

deionized H2O and 2 µl were used for selective

amplification in a total volume of 10 µl containing

1 µmol/L of 10X PCR Buffer, 5 µmol/L of Especific primer extended by 3 selective

neucleotides (Table 2), 5 µmol/L of M-specific

primer extended by 3 selective nucleotides (Table

2), 1 U of Taq DNA polymerase (Fermentas,

Lithuania) and 1 µmol/L of each dNTPs. PCR was

performed using a touchdown protocol with initial

denaturation of a cycle of 30 s at 94°C, 30 s at 65°

C (decreasing the temperature by 1°C after each

cycle until 57°C) and 1 min at 72°C, followed by

30 cycles of 30 s at 94°C, 30 s at 56°C and 1 min

at 72°C with a final extension of 4 min at 72°C.

Following amplification, 10 µl of formamide

loading dye was added to the PCR products. The

products were electrophoresed on 8% nondenaturing polyacrylamide gel. The bands were

visualized using silver stain.

Data analysis

Each accession was scored (1) for

presence and (0) for absence of each polymorphic

band. AFLP bands within accessions were scored

as missing if they were poorly resolved on the gel

or if the template DNA did not amplify well.

Similarity coefficient was calculated on the basis

of Dice similarity coefficients (Dice, 1945) and is

written as

Cjk = 2a/(2a+b+c)

In which Cjk is similarity coefficient, a

is number of AFLP markers present in both j and

k accessions, b is number of AFLP markers present

only in j accessions and c is number of AFLP

markers present only in k accessions. The

similarity matrix was subjected to cluster analysis

by the unweighted pair-group method with

arithmetic mean (UPGMA) and a dendrogram was

created using the NTSYS-pc version 2.01d

program (Rohlf, 1997).

RESULTS

Five informative AFLP primer

combinations generated a total of 364 reproducible

amplification fragments across all species of

Amomum, among which 122 bands were

polymorphic (Table 2). The number of amplified

AFLP bands per primer pair varied from 66 to 81

with an average of 72.8 bands. The average

number of polymorphic bands detected was 24.4

per primer combination. The fragment sizes were

determined by comparing each one with the

standard DNA ladder, ranging from about 140 to

726 base pairs (bp). Two primer combinations (EAGG, M-CAA (Figure 2) and E-ACC, M-CAA)

produced 30 polymorphic bands, a relatively

higher numbers of polymorphisms compared to

the other primers used in this study.

Table 2 AFLP primer pairs and their number of amplified and polymorphic bands for phylogenetic

study of Thai Amomum.

Primer combinations

Amplified bands

No. of polymorphic bands

(EcoRI+3/MseI+3)

E-AGG, M-CAA

81

30

E-ACC, M-CTA

73

17

E-ACC, M-CAA

66

30

E-AGC, M-CTC

74

25

E-AGG, M-CTC

70

20

Total

364

122

Mean

72.8

24.4

Kasetsart J. (Nat. Sci.) 41(2)

Cluster analysis

Cluster analysis using UPGMA

(unweighted pair group method with arithmetic

mean) was performed to examine genetic

relationships among Thai Amomum species. A

dendrogram was produced from the UPGMA

cluster analysis of genetic similarity (GS) matrix

for 45 accessions, 40 accessions of Amomum

species and 5 accessions of out taxa, based on

AFLP markers varied from 43% to 88% with a

total average genetic similarity of 74.5% (Table

3). Two main clusters (A and B) were separated

at 57% GS. The A cluster was separated into 2

groups: C and D, at 58% genetic similarity. The D

group is subdivided into 2 subgroups (I and II) at

59% GS while the B Cluster generated 2 groups

(E and F) at 59% GS (Figure 3).

The A cluster is characterized by spiny

fruit (rarely smooth fruit). The C group contains

Amomum koenigii 1, A. koenigii 2, A.uliginosum

1, Amomum sp.9, Etlingera littoralis, A.

aculeatum, Amomum sp.12 and Geostachys sp.

while D group is divided into two subgroups (I

and II). Subgroup (I) consists of A. testaceum 1,

A. testaceum 2, A. testaceum 3 and Amomum cf.

testaceum. Subgroup (II) consists of A. testaceum

4, A. cf. villosum2, Amomum sp.5, Amomum sp.7,

A. uliginosum2, A. cf. villosum1, A. rivale1, A.

micranthum, A. rivale2, A. cf.rivale, Amomum sp.

8, Amomum sp.4, A. biflorum and Amomum sp.13.

The B cluster is characterized by smooth, ridged

or wing fruit (rarely spiny fruit). This cluster

contains E and F groups. The E group consists

Amomum sp.16, Amomum sp.3, Amomum sp.2,

Amomum sp.17a, A. siamense, Amomum sp.6b,

Amomum sp.6a, Elettaria cardamomum, Amomum

sp.17b, A.dealbatum, Amomum sp.15, Amomum

sp.10 and Alpinia nigra. The F group contains

Amomum sp.1, Amomum sp.14, A. repoense, and

Etlingera pavieana. Regarding the out group taxa;

Alpinia nigra, Elettaria cardamomum and

Etlingera pavieana were inserted in B group while

Etlingera littoralis and Geostachys sp. were placed

in A group.

217

DISCUSSION

In this study, 40 accessions of Thai

Amomum species were fingerprinted including 5

outgroup taxa. One hundred twenty two

polymorphic AFLP markers were produced from

five primer combinations. UPGMA cluster

analysis (Rohlf, 1997) with genetic similarity of

57% separated Amomum into 2 main clusters: A

consists of C and D groups and B consists of E

and F groups (Figure 1).

Regarding the C group, A. koenigii 1 and

A.koenigii 2 were collected from Kanchanaburi

and Nakhon Nayok provinces, respectively. It is

clear that both collections are closely related

(74%), even though the peduncular lengths vary

greatly. The plants from Nakhon Nayok have a

much shorter peduncle than those found in

Kanchanaburi. The variation in phenotype could

be caused by differences in their respective

habitats. The placement of this species is similar

to morphological analysis that placed it in spiny

fruit group. This result is confirmation of the

paraphyletic relationship between A.koenigii and

the spiny fruit species (A. uliginosum and A.

aculeatum). A.aculeatum and Amomum sp.12 are

placed together at 90% GS. These closely related

species are similar in leafy stem but differ in

peduncular length, colour and size of labellum.

From the results, the species Amomum sp.12

should be established as a new variety. However,

this is difficult to decide from only a single plant.

More collections are needed to solve this problem.

D group is divided into two subgroups (I

and II). Subgroup D (I) consists of A. testaceum

1, A. testaceum 2, A. testaceum 3 and Amomum

cf. testaceum. Regarding A. testaceum species

complex, the dendrogram suggests that this species

can be separated into at least three varieties;

especially A. testaceum 4 which was isolated from

the group. The placement of A. testaceum is rather

close to the spiny fruit species (Amomum sp.1 and

Amomum sp.14). This result does agree with Xia

et al. (2004) whose work was based on ITS and

218

Kasetsart J. (Nat. Sci.) 41(2)

MatK genes. They placed A.testaceum among the

spiny fruit species of A.villosum group. A possible

explanation for this was a paraphyletic origin of

A. testaceum complex. Although its morphological

characteristics are different, its genotype is close

Figure 1 Some species of Amomum

A. A. aculeatum Roxb.

D. A.koenigii Gmelin.

G. A. testaceum Ridl.

to spiny fruit species. The Amomum cf. testaceum

that was collected from Chumphon is also placed

in this group. Its leafy stem is similar to A.

testaceum but dif fers in its hairiness on the lower

surface of leaves.

used in AFLP study.

B. A. biflorum Jack

E. A. repoense Pierre ex Gagnep.

H. A. uliginosum K?nig ex Retz.

C. A. dealbatum Roxb.

F. A. rivale Ridl.

I. A. siamense Craib

Figure 2 AFLP fingerprint of Thai Amomum species and out-groups using E-AGG, M-CAA primer pair. 1. A. koenigii1 , 2. A. koenigii 2, 3. Amomum

sp.16, 4. A. testaceum1, 5. A. testaceum 2, 6. A. testaceum 3, 7. A. testaceum 4, 8. Amomum sp.1, 9. A. aculeatum Roxb., 10. Amomum sp.12,

11. A. rivale1, 12. A. rivale2, 13. A.cf. villosum1, 14. A. cf. villosum2, 15. Amomum sp.4, 16. Amomum sp.5, 17. Amomum sp.7, 18. A.

uliginosum1, 19. A. uliginosum2, 20. A. uliginosum3, 21. A Amomum cf. rivale., 22. Amomum sp.17a, 23. Amomum sp.8, 24. Amomum sp.10,

25. A. biflorum Jack , 26. A. micranthum Ridl., 27. Amomum sp.11, 28. Amomum sp.13, 29. none use, 30. none use, 31. A. siamense Craib,32.

.Amomum sp.3, 33. Amomum sp.2, 34. Amomum sp.6b, 35. A. uliginosum4, 36. Amomum sp.17b, 37. A. repoense Gagnep., 38. Amomum sp.6a,

39. none use, 40. Amomum sp.14, 41. Amomum sp.15, 42. A. dealbatum Roxb., 43. Elettaria cardamomum, 44. Etlingera littoralis, 45.

Etlingera pavieana, 46. Alpinia nigra, 47. Geostachys sp., 48.Amomum cf. testaceum and M=φXHinfI

Kasetsart J. (Nat. Sci.) 41(2)

219

A. uliginosum 3

Amomum cf.rivale

A.momum sp.17a

20

21

22

A. uliginosum 1

A. uliginosum 2

18

19

Amomum sp. 5

Amomum sp. 7

16

17

A. cf. villosum 2

Amomum sp. 4

14

15

A. rivale 2

A. cf. villosum 1

12

13

Amomum sp. 12

A. rivale 1

10

11

Amomum sp. 1

A. aculeatum

8

9

A. testaceum 3

A. testaceum 4

6

7

A. testaceum 1

A. testaceum 2

4

5

A. koenigii 2

Amomum sp. 16

2

3

A. koenigii 1

1

0.53

0.55

0.53

0.53

0.67

0.53

0.57

0.61

0.50

0.54

0.57

0.63

0.58

0.59

0.64

0.50

0.57

0.56

0.56

0.58

0.71

1.00

1

0.52

0.57

0.52

0.57

0.83

0.55

0.60

0.63

0.53

0.56

0.59

0.63

0.63

0.65

0.60

0.55

0.57

0.51

0.54

0.57

1.00

2

0.58

0.69

0.57

0.47

0.61

0.52

0.53

0.58

0.43

0.51

0.65

0.61

0.57

0.60

0.60

0.47

0.51

0.47

0.45

1.00

3

0.53

0.59

0.57

0.65

0.57

0.62

0.60

0.68

0.53

0.57

0.57

0.65

0.64

0.66

0.50

0.59

0.78

0.78

1.00

4

0.51

0.57

0.56

0.68

0.56

0.68

0.58

0.68

0.53

0.52

0.55

0.67

0.62

0.63

0.53

0.62

0.88

1.00

5

0.48

0.62

0.54

0.65

0.59

0.64

0.60

0.71

0.53

0.52

0.63

0.68

0.60

0.64

0.57

0.64

1.00

6

0.53

0.63

0.63

0.69

0.53

0.69

0.65

0.64

0.73

0.64

0.65

0.61

0.60

0.56

0.60

1.00

7

0.56

0.64

0.62

0.57

0.60

0.59

0.57

0.60

0.53

0.52

0.67

0.68

0.64

0.61

1.00

8

0.60

0.62

0.56

0.62

0.68

0.60

0.66

0.67

0.58

0.61

0.60

0.65

0.90

1.00

9

0.60

0.58

0.58

0.64

0.64

0.66

0.65

0.64

0.59

0.57

0.59

0.61

1.00

10

0.63

0.72

0.67

0.64

0.63

0.67

0.64

0.80

0.56

0.65

0.76

1.00

11

0.56

0.85

0.64

0.67

0.60

0.67

0.67

0.74

0.64

0.60

1.00

12

0.60

0.62

0.67

0.71

0.60

0.65

0.77

0.71

0.75

1.00

13

0.48

0.64

0.64

0.74

0.51

0.70

0.83

0.62

1.00

14

0.60

0.78

0.69

0.77

0.63

0.75

0.68

1.00

15

0.53

0.68

0.65

0.74

0.64

0.71

1.00

16

0.60

0.66

0.75

0.94

0.55

1.00

17

Table 3 Dice’s coefficient of similarity matrix from AFLP fingerprints of 40 accessions of Amomom and 5 outgroup taxa.

0.50

0.61

0.58

0.58

1.00

18

0.57

0.67

0.74

1.00

19

0.58

0.67

1.00

20

0.60

1.00

21

1.00

22

220

Kasetsart J. (Nat. Sci.) 41(2)

Alpinia nigra

Geostachys sp.

Amomum cf. testaceum

43

44

45

Etlingera littoralis

Etlingera pavieana

41

42

A. dealbatum Roxb.

Elettaria cardamomum

Amomum sp. 15

38

39

Amomum sp. 14

37

40

A. repoense Gagnep.

Amomum sp. 6a

35

36

A. uliginosum 4

Amomum sp.17b

33

34

Amomum sp. 2

Amomum sp. 6b

31

32

A. siamense Craib

Amomum sp. 3

29

30

Amomum sp. 11

Amomum sp. 13

27

28

A. biflorum Jack

A. micranthum Ridl.

25

26

Amomum sp. 8

Amomum sp. 10

23

24

Table 3 (Continued)

0.53

0.57

0.52

0.58

0.69

0.65

0.61

0.57

0.53

0.59

0.53

0.57

0.59

0.58

0.50

0.52

0.54

0.54

0.50

0.53

0.58

0.55

0.55

1

0.49

0.60

0.55

0.58

0.63

0.56

0.64

0.54

0.53

0.54

0.52

0.56

0.67

0.60

0.53

0.53

0.62

0.67

0.54

0.54

0.58

0.50

0.57

2

0.61

0.59

0.55

0.57

0.64

0.60

0.57

0.56

0.57

0.60

0.58

0.60

0.65

0.58

0.66

0.61

0.57

0.65

0.51

0.62

0.61

0.63

0.66

3

0.70

0.55

0.53

0.54

0.56

0.44

0.56

0.57

0.55

0.50

0.50

0.57

0.58

0.54

0.51

0.53

0.58

0.67

0.64

0.61

0.65

0.54

0.57

4

0.70

0.57

0.53

0.57

0.56

0.52

0.57

0.58

0.57

0.47

0.54

0.63

0.58

0.53

0.51

0.51

0.60

0.61

0.69

0.60

0.65

0.53

0.57

5

0.68

0.53

0.50

0.54

0.59

0.53

0.62

0.55

0.53

0.47

0.54

0.58

0.58

0.51

0.50

0.53

0.57

0.63

0.64

0.63

0.68

0.48

0.59

6

0.58

0.60

0.60

0.57

0.52

0.51

0.52

0.56

0.64

0.45

0.55

0.62

0.60

0.53

0.57

0.55

0.54

0.60

0.71

0.71

0.61

0.57

0.61

7

0.57

0.64

0.56

0.71

0.60

0.74

0.70

0.57

0.67

0.55

0.70

0.69

0.57

0.60

0.67

0.64

0.55

0.60

0.60

0.63

0.65

0.59

0.62

8

0.60

0.69

0.56

0.64

0.59

0.57

0.60

0.61

0.57

0.60

0.56

0.63

0.63

0.57

0.51

0.56

0.60

0.66

0.55

0.63

0.60

0.57

0.59

9

0.60

0.65

0.50

0.63

0.60

0.62

0.53

0.57

0.60

0.57

0.52

0.60

0.62

0.58

0.49

0.52

0.64

0.64

0.57

0.62

0.61

0.58

0.55

10

0.63

0.64

0.61

0.67

0.60

0.62

0.63

0.70

0.65

0.59

0.58

0.68

0.65

0.67

0.60

0.63

0.70

0.73

0.62

0.73

0.71

0.60

0.77

11

0.67

0.57

0.50

0.54

0.62

0.58

0.60

0.66

0.66

0.53

0.59

0.64

0.64

0.60

0.56

0.51

0.57

0.75

0.67

0.75

0.71

0.57

0.85

12

0.47

0.61

0.62

0.51

0.60

0.53

0.64

0.66

0.57

0.50

0.57

0.63

0.60

0.57

0.48

0.51

0.58

0.60

0.61

0.63

0.59

0.60

0.65

13

0.53

0.58

0.56

0.47

0.57

0.50

0.54

0.55

0.61

0.43

0.54

0.52

0.58

0.60

0.47

0.48

0.55

0.60

0.67

0.63

0.56

0.53

0.62

14

0.63

0.65

0.61

0.61

0.60

0.51

0.67

0.65

0.57

0.53

0.57

0.65

0.67

0.63

0.57

0.60

0.62

0.71

0.68

0.64

0.69

0.60

0.77

15

0.56

0.61

0.56

0.50

0.64

0.50

0.57

0.58

0.61

0.49

0.51

0.60

0.64

0.60

0.43

0.47

0.58

0.61

0.71

0.61

0.64

0.51

0.67

16

0.53

0.59

0.55

0.58

0.58

0.56

0.55

0.54

0.59

0.56

0.52

0.60

0.62

0.60

0.53

0.57

0.59

0.68

0.81

0.64

0.67

0.53

0.63

17

0.49

0.67

0.52

0.55

0.71

0.57

0.64

0.54

0.56

0.51

0.52

0.62

0.74

0.57

0.53

0.55

0.64

0.64

0.59

0.57

0.64

0.58

0.61

18

0.53

0.62

0.60

0.58

0.58

0.54

0.60

0.59

0.57

0.54

0.55

0.62

0.62

0.58

0.50

0.55

0.59

0.68

0.81

0.64

0.67

0.58

0.66

19

0.55

0.65

0.58

0.61

0.60

0.59

0.60

0.62

0.60

0.51

0.63

0.59

0.62

0.64

0.58

0.61

0.64

0.70

0.73

0.67

0.67

0.61

0.69

20

0.67

0.65

0.55

0.55

0.63

0.53

0.66

0.67

0.64

0.54

0.63

0.64

0.68

0.63

0.57

0.53

0.60

0.78

0.70

0.76

0.71

0.63

0.92

21

0.57

0.60

0.49

0.61

0.57

0.62

0.60

0.68

0.48

0.60

0.64

0.64

0.57

0.64

0.50

0.52

0.60

0.56

0.53

0.56

0.55

0.61

0.60

22

0.66

0.62

0.58

0.53

0.64

0.56

0.67

0.70

0.62

0.54

0.63

0.67

0.67

0.64

0.55

0.57

0.65

0.78

0.65

0.74

0.71

0.66

1.00

23

Kasetsart J. (Nat. Sci.) 41(2)

221

Etlingera pavieana

Alpinia nigra

Geostachys sp.

Amomum cf. testaceum

42

43

44

45

Elettaria cardamomum

Etlingera littoralis

40

41

Amomum sp. 15

A. dealbatum Roxb.

38

39

Amomum sp. 6a

Amomum sp. 14

36

37

Amomum sp. 17b

A. repoense Gagnep.

34

35

Amomum sp. 6b

A. uliginosum 4

32

33

Amomum sp. 3

Amomum sp. 2

30

31

Amomum sp. 13

A. siamense Craib

28

29

A. micranthum Ridl.

Amomum sp. 11

26

27

Amomum sp. 10

A. biflorum Jack

24

25

Table 3 (Continued)

0.60

0.70

0.67

0.64

0.55

0.60

0.64

0.67

0.54

0.62

0.71

0.70

0.59

0.69

0.66

0.69

0.65

0.64

0.57

0.62

0.60

1.00

24

0.64

0.64

0.55

0.63

0.67

0.57

0.63

0.65

0.70

0.56

0.61

0.70

0.65

0.55

0.58

0.58

0.57

0.74

0.73

0.67

1.00

25

0.65

0.64

0.56

0.59

0.54

0.63

0.54

0.67

0.66

0.57

0.68

0.58

0.66

0.60

0.57

0.57

0.58

0.75

0.63

1.00

26

0.62

0.57

0.54

0.56

0.57

0.49

0.56

0.57

0.61

0.52

0.57

0.67

0.57

0.53

0.53

0.51

0.57

0.64

1.00

27

0.65

0.64

0.59

0.59

0.59

0.53

0.59

0.64

0.64

0.60

0.60

0.63

0.74

0.65

0.60

0.64

0.64

1.00

28

0.51

0.67

0.56

0.60

0.62

0.66

0.59

0.60

0.52

0.67

0.54

0.63

0.64

0.82

0.57

0.60

1.00

29

0.53

0.65

0.61

0.63

0.55

0.59

0.61

0.54

0.60

0.57

0.61

0.62

0.60

0.63

0.88

1.00

30

0.60

0.62

0.57

0.63

0.57

0.59

0.63

0.53

0.64

0.57

0.58

0.64

0.57

0.58

1.00

31

0.55

0.70

0.58

0.57

0.60

0.68

0.64

0.65

0.47

0.71

0.60

0.65

0.62

1.00

32

0.54

0.63

0.54

0.54

0.71

0.55

0.59

0.58

0.61

0.52

0.54

0.52

1.00

33

0.59

0.71

0.54

0.67

0.62

0.61

0.74

0.72

0.60

0.66

0.62

1.00

34

0.63

0.62

0.61

0.69

0.58

0.67

0.66

0.64

0.59

0.56

1.00

35

0.53

0.57

0.54

0.59

0.53

0.69

0.60

0.69

0.43

1.00

36

0.54

0.60

0.54

0.64

0.60

0.53

0.57

0.55

1.00

37

0.65

0.64

0.53

0.60

0.53

0.61

0.70

1.00

38

0.57

0.62

0.60

0.63

0.69

0.59

1.00

39

0.53

0.64

0.51

0.57

0.60

1.00

40

0.55

0.54

0.49

0.52

1.00

41

0.57

0.64

0.64

1.00

42

0.44

0.57

1.00

43

0.54

1.00

44

1.00

45

222

Kasetsart J. (Nat. Sci.) 41(2)

Kasetsart J. (Nat. Sci.) 41(2)

223

Figure 3 Dendrogram depicting the genetic relationship of 45 accessions of Amomum based on AFLP

fingerprint, using similarity coefficient by DICE, clustering with UPGMA.

224

Kasetsart J. (Nat. Sci.) 41(2)

Subgroup D (II) consists of A. testaceum

4, A. cf. villosum, Amomum sp.5, Amomum sp.7,

A. uliginosum 2, Amomum sp.11, A. uliginosum 3,

A. villosum 1, A. rivale 1, A. micranthum, A. rivale

2, A. cf. rivale, Amomum sp.8, Amomum sp.4 and

Amomum sp.13. All members have spiny fruit and

leafy stem less than 1.50 m tall. Regarding

uliginosum 2 and 3 which were collected from Tak

province, they were separated from A. uliginosum

1 and 4 (from Nakhon Nayok and Ranong

provinces, respectively). Their morphological

characteristics differ from the ones in C group in

its shorter leafy stem and smaller inflorescence.

A possible explanation for this is that their

morphological characteristics were the result of

long time adaptation in the surrounding habitats

which resulted in two ecotypes of A. uliginosum.

B cluster consists of E and F groups. It

is characterized by smooth, ridged or winged fruit

(rarely spiny fruit).

E and F groups include Amomum sp.16,

Amomum sp.3, Amomum sp.2, Amomum sp.17a,

A. siamense, Amomum sp.6b, Amomum sp.6a,

Amomum sp. 17b, A. dealbatum, Amomum sp. 15,

Amomum sp. 10, Elettaria cardamomum, Alpinia

nigra, Amomum sp. 1, Amomum sp.14, A. repoense

and Etlingera pavieana.

The dendrogram suggests the placement

of smooth fruit (Amomum sp.16) between spiny

and winged fruit. Similar to the result of Amomum

sp.1 and 10 both of which are spiny fruit but were

placed among winged fruit species. Amomum

sp.17a and 17b from Nan province are similar in

their morphology but were placed in different

clusters. More study is needed to properly identify

the position of these species. A.siamense with fruit

longitudinally ridged is also placed in this group.

This species should be closely related to winged

fruit species. Although the cluster is not completely

separated from the others, all winged fruit species

are clearly placed. Therefore, the results have the

tendency to be consistent with the A.maximum

group of Xia et al. (2004).

The outgroup taxa (Alpinia, Elettaria,

Etlingera and Geostachys) are placed among

Amomum species. The result indicates a closer

relationship among them and the spiny fruit species

of Amomum. This result is similar to Xia et al.

(2004) who found that Etlingera littoralis was

placed in the clade of A.villosum group. The results