Read Article

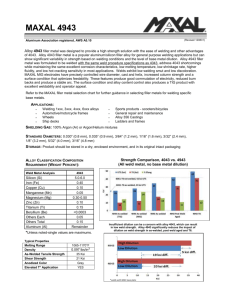

advertisement

e h t n e h W g oing H G U O T S T GE Jon S. Lee and Tom J. Landon, CB&I, USA, discuss how to improve the toughness of high heat input welded vertical joints. reprinted from HydrocarbonEngineering June2007 www.hydrocarbonengineering.com W hen it comes to welding the vertical joints of atmospheric flat bottom storage tanks, it is common practice to use a high heat input electrogas welding (EGW) process to achieve maximum productivity while maintaining acceptable quality. The EGW process can be used to weld joints up to 1 in. (25 mm) thick in a single pass, and takes about 1.2 hours to weld an 8 ft (2438 mm) vertical seam. Compared with the 5.3 hours it takes to weld the same seam using a conventional flux cored arc welding (FCAW) process, this represents a 400% improvement in productivity. The trade off for using the EGW process, however, is a reduction in notch toughness, which is a result of the high welding heat input. Traditional industry practice shows that the EGW process is capable of achieving adequate joint toughness down to 0 ˚F (-18 ˚C). At test temperatures below this point, typical joint details and welding consumables may not consistently provide code minimum toughness, particularly in the weld metal. In an effort to expand process utilisation, CB&I, a global engineering, procurement and construction contractor, has developed and field tested a new EGW technique, based on lower joint volume and better welding materials, that improves weld metal and heat affected zone toughness at temperatures down to -40 ˚F (-40 ˚C). The new technique is based on electrogas welding equipment that CB&I specifically developed for API-650 storage tanks in cold weather environments (Figure 1). The unit includes a mobile power supply that can be moved with the EGW delivery platform from one vertical seam to the next on each ring of the tank. This combination of power supply and mechanised delivery results in a safe and efficient means of implementing mobile ment with ip the EGW process while u q e W EG Figure 1. nk. eliminating the constraint of pply on ta u s r e w po welding cables going to the bottom of the tank. In developing the new EGW technique, an evaluation of various joint designs and welding consumables was conducted to ensure adequate joint toughness at -40 ˚F (-40 ˚C). Joint details and welding techniques were likewise evaluated to reduce joint volume and heat input. Welding consumable formulations were studied to identify the optimum chemistry and weld metal microstructure. Based on these evaluations and the subsequent results, it was concluded that the toughness in the weld metal and heat affected zone (HAZ) can be improved using lower heat input welding techniques and properly selected welding consumables. Joint detail The most critical factor in improving toughness in the weld metal and HAZ is reducing the joint volume, which is Figure 2. Joint detail. Conventional EGW process. 1 in. (25 mm) thick especially critical for plate material. thicknesses nearing 1 in. (25 mm). As the joint is being welded in a single pass, a small joint volume results in significantly lower welding heat input. Table 1 provides a comparison of typical welding parameters between conventional electrogas welding using a standard joint configuration and Figure 3. Joint detail. 'Narrow groove' EGW process. 1 in. (25 mm) thick material. electrogas welding www.hydrocarbonengineering.com reprinted from June2007 HydrocarbonEngineering Table 1. Welding parameters and heat input Process Bevel angle (˚) AWS electrode class Electrode diameter, in. (mm) Current (amps) Voltage Travel speed, in./min (mm/min) Heat input, KJ/in (KJ/cm) EGW conventional EGW narrow groove 55 EG72T-1 3/32 (2.4) 560 47 3.7 (94) 425 (1080) 25 EG72T-G 1/16 (1.6) 440 44 3.8 (97) 308 (782) Table 2. CVN toughness of HAZ. CSA G40.21 Grade 38WT (as rolled) steel. 1 in. (25 mm) thick Process CSA G40.21 Gr.38WT Notch location Test temperature, ˚F (˚C) CVN Spec, 1 ft-lbs (joules) CVN Spec, 2 ft-lbs (joules) CVN Spec, 3 ft-lbs (joules) CVN AVG, ft-lbs (joules) Base metal -20 (-29) 73 (99) 15 (20) 16 (22) 35 (47) EGW conventional HAZ 0 (-18) 93 (126) 115 (156) 89 (121) 99 (134) EGW conventional HAZ -10 (-23) 23 (31) 19 (26) 17 (23) 20 (27) 20 (27) RGW conventional HAZ -20 (-29) 7 (9) 39 (53) 13 (18) CSA G40.21 Gr.38WT Base metal -40 (-40) 21 (28) 10 (14) 33 (45) 21 (28) EGW - narrow groove HAZ -20 (-29) 95 (129) 75 (102) 90 (122) 87 (118) EGW - narrow groove HAZ -40 (-40) 24 (33) 34 (46) 37 (50) 32 (43) EGW - narrow groove HAZ -40 (-40) 54 (73) 97 (132) 78 (106) 76 (103) EGW - narrow groove HAZ -60 (-51) 55 (75) 72 (98) 65 (88) 64 (87) 1. All specimens taken within 1/16 in. surface of first side (bevel side) of test plate 2. All specimens taken longitudinal direction to plate primary rolling direction (PRD) 3. All CVN specimens per ASTM A370 (V-notch) of 10 x 10 mm size Table 3. CVN toughness of welds. CSA G40.21 grade 38WT (as-rolled) steel 1 in. (25 mm) thick Process Notch location Test temp, ˚F (˚C) CVN spec 1, ft-lbs (joules) CVN spec 2, ft-lbs (joules) CVN spec 3, ft-lbs (joules) CVN AVG, ft-lbs (joules) EGW conventional Weld metal -20 (-29) 20 (27) 21 (28) 21 (28) 21 (28) EGW conventional Weld metal -30 (-34) 19 (26) 19 (26) 19 (26) 19 (26) EGW conventional Weld metal -40 (-40) 19 (26) 21 (28) 25 (34) 22 (30) EGW - narrow groove Weld metal -20 (-29) 86 (117) 94 (127) 90 (122) 90 (122) EGW - narrow groove Weld metal -40 (-40) 44 (60) 38 (52) 47 (64) 43 (58) EGW - narrow groove Weld metal -40 (-40) 65 (88) 69 (94) 69 (94) 68 (92) EGW - narrow groove Weld metal -60 (-51) 62 (84) 56 (76) 55 (75) 58 (79) reprinted from HydrocarbonEngineering June2007 Conversely, the ‘narrow groove’ EGW process utilises both a smaller diameter (1/16 in. or 1.6 mm) electrode and an oscillating system to achieve full joint fusion in the reduced volume detail. Oscillating the electrode enables the EGW process to achieve full fusion and provides the added benefit of stirring the molten weld puddle, which results in a measure of grain refinement. As with joint volume, optimum oscillation is a key component for improving toughness in high heat input EGW welds. CB&I experimented with different oscillation characteristics during the development of the process and found that the oscillation range, or stroke length with respect to the midpoint of the joint thickness, has a significant influence on the front and backside weld profiles. In addition, the speed of oscillation, measured in cycles per minute, has a substantial impact on the weld metal grain structure due to the stirring effect. Materials It was important that CB&I improve joint toughness EGW - narrow groove Weld metal -80 (-62) 42 (57) 49 (66) 59 (80) 50 (68) (as measured by Charpy 1. All specimens taken within 1/16 in. (1.6 mm) from the surface of first side (bevel side) of test plate V-Notch Impact Testing) 2. All welding completed in CSA G40.21 Gr.38 WT Plate 1 in. (25 mm) thickness down to -40 ˚F (-40 ˚C) so 3. All CVN specimens per ASTM A370 (V-notch) of 10 x 10 mm size that the EGW process could be used on API-650 storage tanks in Canada. Use of with a joint configuration for narrow groove (low volume) the process in Canada is driven not only by the improved welding (basic joint details are provided in Figures 2 and 3 productivity that can be obtained, but also by the need to find and resulting weld cross-sections in Figures 4 and 5). When alternative welding resources. properly executed, the ‘narrow groove’ EGW process reduces As with much of the world, Canada is experiencing a the welding heat input in a 1 in. (25 mm) thick joint by significant increase in the demand for qualified welding approximately 27%. personnel; however, available resources are currently strained. The opportunity to use the EGW process in an area Oscillation where it was not previously qualified for use can provide The EGW process used for both conventional and ‘narrow some relief on these demands. Understanding this driver was groove’ weld details uses a solid copper backup bar on the instrumental in determining the materials to be specified for back side of the joint and a sliding water cooled copper the welding applications. shoe on the front side of the joint, allowing the weld metal Improving the toughness capabilities of the EGW process to essentially be cast in place. In the conventional EGW requires that both the weld metal and HAZ toughness application, the electrode is held in a fixed position in the meet code or contract acceptance criteria. To meet these centre of the joint without any oscillation. When using this requirements in the HAZ, material selection and heat input technique, a relatively large diameter electrode (3/32 in. or reduction are both important factors to consider. The material 2.4 mm) and an increased bevel angle is required to achieve of choice for storage tanks in Canada with a minimum design complete fusion with adequate buildup on both plate surfaces. metal temperature of -40 ˚F (-40 ˚C) is CSA G40.21 Grade 38WT www.hydrocarbonengineering.com Figure 4. Weld bead profile on cross-section. Conventional EGW process. 1 in. (25 mm) thick material. fusion line between the weld metal and base material, where minimal grain refinement from the heat of welding had taken place. To evaluate the most critical zone, the HAZ notch was machined in the coarse grain region near the edge of the fusion line, as shown in Figure 6. Electrode Figure 5. Weld bead profile on cross-section. 'Narrow groove' EGW process. 1 in. (25 mm) thick material. Figure 6. Typical notch location for HAZ impact specimen. carbon steel, typically furnished in ‘as rolled’ condition. This material is very similar to ASTM A36 carbon steel. When the EGW process is anticipated, the tank material must be controlled by additional purchasing specifications, including restrictions on maximum carbon content, minimum manganese content and the maximum amount of low melting point elements such as sulfur and phosphorus. Table 2 provides typical data on HAZ toughness for joints welded with the EGW process using a single pass. The data compares HAZ impact results for both the conventional process and the ‘narrow groove’ welding process. For comparison purposes, the required toughness for this material, as specified in API-650, is an average of 15 ft-lbs (20 joules) for three specimens, with one specimen allowed to be below the average, but no less than 10 ft-lbs (14 joules). HAZ specimens were machined in accordance with API-650 requirements, with the notch positioned to include as much of the HAZ material as possible in the fracture zone. Fracture initiation was deemed to be most critical at the www.hydrocarbonengineering.com Meeting toughness requirements at the design metal temperatures necessary for the storage of petroleum products in low temperature environments is also a challenge for the deposited weld metal. Most commercially available welding consumables used in the EGW process are classified as AWS EG72T-1 electrodes and are designed to meet Charpy V-Notch impacts of 20 ft-lbs (27 joules) average at -20 ˚F (-29 ˚C) per AWS specification A5.26/A5.26M-97. To achieve acceptable weld metal toughness at lower test temperatures, CB&I turned to Devasco International of Houston, Texas. Devasco is a manufacturer of custom made and proprietary welding consumables that have special mechanical properties. A number of test electrodes were manufactured by Devasco and shipped to CB&I’s welding laboratory for welding and mechanical testing. Chemistry modifications and batch testing progressed until an EG72T-1­ electrode formulation was derived that would consistently meet needed impact properties at -40 ˚F (-40 ˚C). From this initial formulation, additional variations have been developed that are able to achieve both good low temperature toughness and weld metal hardness below 225 BHN. The electrode and its variations are produced exclusively for CB&I as an AWS EG72T-G classification. Using the ‘narrow groove’ EGW process, the Devasco electrode will produce weld metal Charpy V-notch impacts exceeding 20 ft-lbs (27 joules) average at -40 ˚F (-40 ˚C). Table 3 provides information on weld metal toughness, comparing results for the EG72T-1 electrodes using the conventional EGW process with proprietary EG72T-G electrodes using the ‘narrow groove’ EGW process. It should be noted that the base material has a significant influence on impact properties because dilution of the base metal accounts for 30 - 40% of the weld metal composition in single-pass EGW welding. EGW consumables are formulated to account for this dilution, but welding on different grades of carbon steel materials can produce significantly different weld metal toughness results. The improvement in weld metal toughness is also aided by the reduction in heat input, which is a result of the narrow groove and smaller weld volume. And finally, the electrode oscillation also results in better weld metal toughness, compared with no oscillation in conventional EGW welding, by facilitating a more rapid solidification of the weld nugget and finer grains in the weld deposit. Conclusion Based on this study, CB&I has concluded that by using enhanced techniques and materials, the weld metal and HAZ toughness of vertical welds in carbon steel flat bottom storage tanks made with the EGW process can be significantly improved. The narrow groove low volume weld detail, electrode oscillation, careful material selection and specially developed welding consumables are all instrumental in achieving acceptable impact results at test temperatures at or below -40 ˚F (-40 ˚C). reprinted from June2007 HydrocarbonEngineering