Biochemistry of cheese ripening

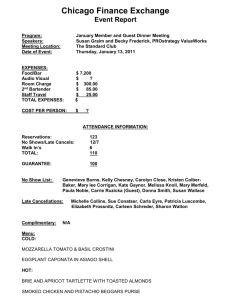

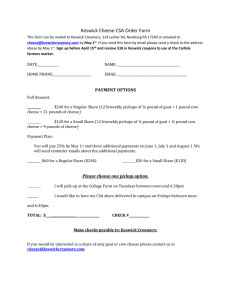

advertisement