Cadbury & Carbon Foot-printing

advertisement

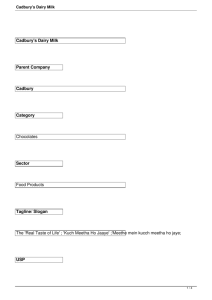

Cadbury & Carbon Foot-printing By Ian Walsh Cadbury like many others is on a carbon footprinting journey. • • • • Our ultimate destination is to footprint the entire supply chain • Identify areas for focus • Capture joint benefits We haven’t got there just yet. We’ve tried various routes Our progress is accelerating rapidly As we move towards carbon foot-printing we face many challenges • • • There is a balance between credibility and practicality. This is not a zero cost exercise The journey cannot be undertaken in isolation Complex supply chains have potential for major road blocks • • • • • Flexible manufacturing asset base Seasonal production Global sourcing Vast product range Complex recipes • • • Data integrity Data availability Excessive costs Developing a standard approach will get us to where we want to be. • • • Increased credibility Easy benchmarking Increased understanding CSplc reports it’s in house emissions and direct transport emissions. • GRI groups 1 & 2 • Carbon disclosure project top 60 We measure fuel use at site level and calculate carbon emissions. • • • Gas used for steam raising Oil used as standby fuel Power from the grid • • Need to know generating mix Also account for on site generation. We have adopted and developed a web based M&T system We are introducing line level monitoring at key sites. We record the mileage of vehicles and calculate emissions • • • Type and age of vehicle Total mileage Mpg Published conversion factors are used to calculate emissions. • Avoids confusion • Easier verification. • UK government and IPCC figures used We have struggled to get reliable data from suppliers using generic mail-shots. • • • • • We have 100’s of suppliers on our database. Many smaller suppliers do not measure the required data. The request is too general Superfluous questions No clear importance or purpose. We have started to develop footprints for individual brands • • • • Complimentary to the overall company footprint reported Allows the scope of the footprint to be extended along the supply chain. Allows for closer definition In line with the move towards product labelling. Cadbury suppliers customers Brand X Plant A Plant B We are beginning with CDM and Green & Blacks • • • • Cadbury has 100’s of product lines globally. Green & Blacks obvious choice Cadbury Dairy Milk is the flagship brand We have further the scope to single product lines. We are working with the carbon trust using their methodology. • • • • We have used consultants to help pull together some information. The carbon trust are independent and commercially neutral Other companies have already worked with the methodology The Carbon Trust have credibility with stakeholders Not all plants have enough sub-metering • Clip on ammeter – for monitoring current draw and calculating power • Bucket test – physically breaking steam mains after the trap to measure flow. • Ultrasonic flow meters – measuring water flows in hot and cold services • Infra red temperature sensors – flow and return temperatures in services. We have approached key suppliers for information >98% We have used short concise questionnaires tailored to the supplier • • • • Need to collect sufficient information Easy to complete Not excessively time consuming. Need to tread carefully around the issue of commercial sensitivity. We intend to repeat the exercise for a number of our leading UK brands • As lines are completed a live database will be developed. We are working to create a reproducible methodology. • • • We are actively working with the carbon trust Having an agreed methodology will enable future benchmarking The method must be credible and practical We are keen to liaise with retailers, manufacturers and others.