John Dowling BCSA

advertisement

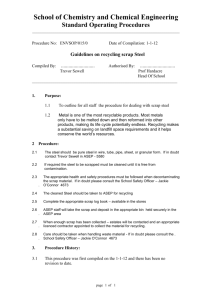

Resource efficiency, construction and the circular economy Alliance for Sustainable Building Products: 27th February 2013 John Dowling Sustainability Manager, British Constructional Steelwork Association Mineral reserves We know very little about real reserves and there is much to be discovered This gives an indication of the reserves of discovered iron ore at current consumption Latest best estimates indicate 500 years supply of iron ore The steel cycle in construction Product manufacture Raw materials acquisition Steel manufacture Intermediate processing Construction Disposal Demolition In use Steel production worldwide • Steel can be manufactured using 100% scrap or from a mixture of scrap and iron ore • World steel production is approximately 1500 million tonnes. • Of this, approximately a third is from recycled scrap. • The scrap capture infrastructure works at over 80% efficiency. • Thicker, heavier products are more likely to be made from the scrap route and light gauge material is more likely to be made from the iron ore route. WARNING Never specify metals on the basis of recycled content. It will not improve recycling rates and may be counterproductive Recycling and reuse rates for steel in construction Structural Sections Purlins & rails Cladding Decking Rebar Internal Non-structural Steel Recycling % 86 89 79 79 91 85 Reuse % 13 10 15 6 1 2 Landfill % 1 1 6 15 8 13 There is nothing new about reusing structural steel Honda in Swindon: dismantled, stored and rebuilt Prologis Park, Heathrow • Design for disassembly and re-use • Clear identification of each piece • Result: 80% re-usable There is nothing technically difficult about reusing structural steel. • So why isn’t it done more often? • Difficulty in guaranteeing properties? • Who will take responsibility? • Difficulty in dismantling structures (time)? • The nature of the demolition industry? • Lack of critical mass? Implications of reuse • Potential move away from composite construction in some cases. • Changes in deconstruction/demolition practice. • Bolted rather than welded assemblies. The onus is on the construction sector to provide buildings in a manner which: • • • • Minimises resource use Minimises lifetime cost and resource burdens Minimises energy use Guarantees long and useful life. Features of buildings of the future • Low operational energy. • Flexible and adaptable to maximise life span and future proof the building. • Design for easy refurbishment and renovation. • Use materials which can be easily recovered and which have high recycling and reuse potential. • Design for recovery, re-use and demountability at end of life. • Maximise the amount of work done off-site. • Use construction materials and methods which minimise waste. National Trust HQ, Swindon • • • • • • • • • • BREEAM excellent Brownfield development Naturally ventilated Quick construction Long-span flexibility Shallow structural zones Lighter foundations Thermal mass Heat recovery Photovoltaics Manchester Civil Justice Centre • • • • BREEAM excellent Natural ventilated Naturally lit Environmental veil and light shelves • Double-skin facade • Borehole cooling Building longevity The value of a building can be maximised by considering flexibility and adaptability in design. Long spans construction is one possible solution. It allow the space to be arranged to suit open floor plans, different layouts of cellular offices and variations in layout throughout the height of the building. Building longevity • This is an example of modern building life extension • The existing roof / wall coverings were completely removed and replaced with composite panels. • The U value and air-tightness of the building were immediately improved. • The portal frame was raised by 3m and an office block added Building longevity Can we measure flexibility and adaptability? • Not a lot of work has been done on this. • A PhD thesis at the University of Delft has resulted in the development of a simplified assessment method. • This looks at six parameters and their effect on the Estimated Service Life (ESL) of the building. • An ESL<1 means a reduced service life and an ESL>1 means an extended service life. • Low score= 0,9*0,7*0,8*0,85*0,9*0,8 = 0,3 (reduce ESL -70%) • High score =1,1*1,4*1,2*1*1,3*1,2= 2,9 (increase ESL +190%) • So, the difference between the impact of best and worst practice in design for building longevity is almost a factor of 3. The DUTCH version of BREEAM recognises the importance of this 2 credits Social and ethical considerations So, where are the problems? • The following comments reflect my personal opinion and not necessarily those of my employer. • The construction industry remains cost driven. • It is difficult to change practice. • The cost of carbon remains low. • Each building is a one-off. There is no standardisation. • We have failed to match many of the aspirations of the Egan Report (for example) Independent: 20th February 2013 Thanks for listening