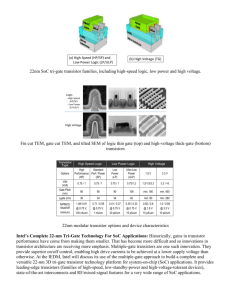

Physical limits of silicon transistors and circuits

advertisement