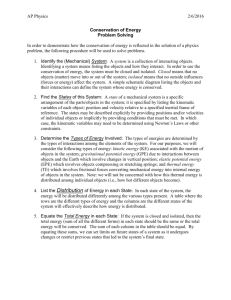

Workplace Risk Assessment

advertisement