Experimental study on R-134a refrigeration system

advertisement

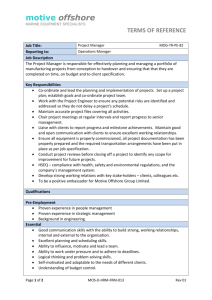

Experimental study on R-134a refrigeration system using a two-phase ejector as an expansion device Praitoon Chaiwongsa, Somchai Wongwises * Fluid Mechanics, Thermal Engineering and Multiphase Flow Research Laboratory (FUTURE), Department of Mechanical Engineering, King Mongkut’s University of Technology Thonburi, Bangmod, Bangkok 10140, Thailand Received 8 May 2006; accepted 14 May 2007 Available online 2 June 2007 Abstract This paper is a continuation of the authors previous work. In the present paper, the performance of the refrigeration cycle using a two-phase ejector as an expansion device is experimentally investigated. Refrigerant R-134a is used as working fluid. Motive nozzles having three different outlet diameters are tested. New experimental data that have never been seen before are presented on the effects of the external parameters i.e. heat sink and heat source temperatures on the coefficient of performance and various relevant parameters i.e. primary mass flow rate of the refrigerant, secondary mass flow rate of the refrigerant, recirculation ratio, average evaporator pressure, compressor ratio, discharge temperature and cooling capacity. The effects of size of the motive nozzle outlet on the system performance are also discussed. Ó 2007 Published by Elsevier Ltd. Keywords: Two-phase ejector; Refrigeration; Liquid-recirculation; Coefficient of Performance; Motive nozzle; Expansion device 1. Introduction In vapor refrigeration cycle, in order to accommodate the low temperature evaporation process, a saturated or sub-cooled liquid produced from condensation at high temperature must be expanded through an expansion device to low-pressure. Throttling process or isenthalpic process is the process occurring through an expansion device. This process produces the thermodynamic losses and causes a larger amount of the refrigerant to flash into a vapor than in the isentropic process. In order to reduce the thermodynamic loss in the expansion process, various researchers have attempted to look for other appropriate devices. Due to the low cost, no moving parts and ability to handle two-phase flow without damage, an ejector is considered as an attractive expansion device in the refrigeration system. * Corresponding author. Tel.: +662 470 9115; fax: +662 470 9111. E-mail address: somchai.won@kmutt.ac.th (S. Wongwises). 1359-4311/$ - see front matter Ó 2007 Published by Elsevier Ltd. doi:10.1016/j.applthermaleng.2007.05.005 To the best of the authors’ knowledge, information on the application of an ejector as an expansion device in a refrigeration cycle is still limited. Kornhauser [1] investigated the thermodynamic performance of the ejector expansion refrigeration cycle by using R-12 as a refrigerant under standard conditions, 15 °C and 30 °C for evaporator and condensor temperatures, respectively. A theoretical COP improvement of up to 21% over the standard cycle was found. This result was based on ideal cycle and constant mixing pressure in the ejector. Harrell et al. [2] used a R-134a two-phase ejector and the test rig to estimate the COP of the refrigeration cycle. It was found that the COP improvement ranged from 3.9% to 7.6%. Menegay et al. [3] developed a bubbly flow tube to reduce the thermodynamic non-equilibrium in the motive nozzle with R-12 as the refrigerant. This device was installed upstream of the motive nozzle. The COP of the system using the bubbly flow tube can be improved up to 3.8% over the conventional cycle under standard conditions. However, they reported that the result was not as good as was expected and study of the ejector expansion Nomenclature COP cp,hw Dni Dnt Dne Lni Lnc Lnd m_ p m_ s m_ e m_ hw coefficient of performance specific heat at constant pressure of the hot water (kJ/kg k) inlet diameter of motive nozzle (mm) throat diameter of motive nozzle (mm) outlet diameter of motive nozzle (mm) inlet length of motive nozzle (mm) convergent length of motive nozzle (mm) divergent length of motive nozzle (mm) primary mass flow rate of refrigerant (kg/s) secondary mass flow rate of refrigerant (kg/s) flow rate of the vaporized refrigerant (kg/s) mass flow rate of hot water (kg/s) refrigeration cycle should be extended. Domanski [4] concluded that the ejector efficiency was very sensitive to the theoretical COP of the ejector expansion refrigeration cycle. Nakagawa et al. [5] showed that the longer divergent part provided a longer period of time for the two-phase flow to achieve equilibrium. He concluded that the longer the length of the divergent part of the motive nozzle, the higher the motive nozzle efficiency could be obtained. The papers mentioned above focused on operating with a dry-expansion evaporator by installing an expansion valve downstream of the liquid-vapor separator. However, the purpose of the ejector is to replace the throttling valve. With this consequence, any throttling device in the system should be avoided. Up to now, there have been only two papers, published by Disawas and Wongwises [6] and Wongwises and Disawas [7], dealing with this issue. In their experimental apparatus, the evaporator was flooded with refrigerant and became a liquid-recirculation system, in which, in addition to serving as an expansion device, the ejector also acted as a refrigerant pump for the low-pressure side of the system. Although, some information is currently available on the refrigeration cycle using a two-phase ejector as an expansion device, the detailed investigation is still lacking. Especially, it can be noted that no attention has been paid to the effects of geometric parameters on the performance of the refrigeration system. This paper is the third in a series and is a continuation of the authors’ previous work. The main concern of the present study is to experimentally investigate the effect of the external parameter i.e. heat sink temperature and heat source temperature, the effect of relevant geometric parameters of the ejector on the performance of the refrigeration cycle using a two-phase ejector as an expansion device. Moreover, the effect of the outlet diameter of the motive nozzle on the performance of the refrigeration system, which has never before appeared in the open literature, is presented. me ne Qevap se Tsink Tsource Thw,in Thw,out Wcomp mixing chamber exit motive nozzle exit heat transfer rate at evaporator (kW) suction nozzle exit heat sink temperature (°C) heat source temperature (°C) hot water temperature at the inlet of the evaporator (°C) hot water temperature at the outlet of the evaporator (°C) electrical power supplied to the compressor (kW) 2. Experimental apparatus and procedure Fig. 1 shows the schematic diagram of the experimental apparatus. A commercial R-134a is used as the working fluid. The refrigerant loop consists of the vapor compression cycle components: compressor, condenser, expansion valve and evaporator, and other accessory parts – the oil separator, liquid receiver, filter/drier, sight glass and the accumulator. The operating conditions of the apparatus are similar to those of a typical air-conditioning application. The principal modifications from the standard refrigeration system are the addition of a two-phase ejector and a liquid–vapor separator. Refrigerant is discharged by a two-cylinder single stage reciprocating unit, driven by an electric motor. The speed of the motor is varied by an inverter to regulate the refrigerant flowing through the motive nozzle. Compact plate heat exchangers are used for the condenser and evaporators. The evaporator referred to in this paper is the main evaporator as shown in Fig. 1. A filter/drier, placed downstream of the receiver, is provided to keep the circulating refrigerant free from harmful substances: moisture and foreign particles that might remain in the system. An oil separator is used to keep the oil content in the refrigerant to a minimum. The motive and the suction mass flow rates are measured by volumetric flow meters located downstream of the sight glass and of the liquid-vapor separator, respectively. All flow meters are specially calibrated for R-134a from the manufacturer. The total capacity of all refrigerant flow meters is 0.3 to 3.3 LPM. The manufacturer’s listed accuracy is 0.1% of the full scale. The temperatures are measured by T-type thermocouples having accuracy of 0.1 °C. All the temperature-measuring devices are well calibrated in a controlled temperature bath using standard precision mercury glass thermometers. Bourdon gauges, calibrated against the dead weight test, are used to measure the pressures. All static pressure taps are mounted flush in Oil Separator Condenser 2′ Stirrer RTD By-Pass Valve CDU Electrical Heater Condensing Unit . mp 1 Inverter Sight Glass Cold-Water Pump Cold-Water Tank 2 3 Flow Meter Compressor Motor Filter-Drier Receiver Sight Glass Primary Flow Meter . mp OC/CE OE/CC . . m p+ ms Ejector OE/CC 3′ 4 LiquidVapor Separator OE/CC . ms Accumulator OC/CE 6 . ms Expansion Valve Main Evaporator Secondary Flow Meter OE/CC 5 Sight Glass Sub-Evaporator Flow Meter Stirrer RT By-Pass Valve Hot-Water Pump Electrical Heater P T Condenser Liquid-Vapor Separator 4 . mp . . m p + ms 1 ne se me Ejector . ms 6 : Pressure Gauge (High/Low) : Thermocouple (T-Type) 2′ 3 3′ Hot-Water Tank OE/CC : Open for Ejector Mode, Closed for Conventional Mode OC/CE : Open for Conventional Mode, Closed for Ejector Mode Evaporator 2 Compressor 5 Fig. 1. Schematic diagram of experimental apparatus. the tube wall. Please note that the sub-evaporator shown in Fig. 1 was not used in the present study. It was prepared for the experiment with high cooling load. The main evaporator has enough capacity for the cooling load used in the present study. In order to collect data at various conditions, the heat load to the evaporator is supplied by using the hot water loop. The water in the tank is heated with a 4.5 kW electric heater and supplied through the evaporator by the circulating pump. The condenser rejects heat to the water coming from a cold water tank. The water is cooled by a separated refrigeration system using R-22 as refrigerant. The separated refrigeration system consists of a condensing unit with a capacity of approximately 2.6 tons of refrigeration, Mixing Chamber Motive Nozzle Diffuser Mixed Refrigerant Primary Refrigerant Suction Chamber Secondary Refrigerant Nozzle Rod O-Rings φ22.0 Mixing Chamber and Diffuser φ10.0 Motive Nozzle φ30.0 Locking Nut Suction Chamber 30.0 110.0 90.0 Fig. 2. Ejector assembly. a capillary tube, filter/drier, sight glass and a helical copper tube coil immersed in water being cooled in an insulated tank. The test runs are done at the cooling load ranging between 1.8 and 3.0 kW. The schematic diagram of the two-phase ejector as shown in Fig. 2, is designed in three main parts: the motive nozzle, the suction chamber, and the mixing chamber with diffuser. The motive nozzle throat area is designed according to the Henry and Fauske model [8]. This model is used because it considers the metastable effect of the expansion of saturated liquid into the liquid–vapor mixture region. The remaining cross-sectional areas of the ejector are designed according to the homogeneous equilibrium model (HEM) (Kornhauser [1], Sherif et al. [9]). HEM is based on the assumption that vapor and liquid are in thermal and mechanical equilibrium. Furthermore, the mixing process is assumed to occur at constant pressure. The other dimensions, including the lengths of each section and the convergent and divergent angles, are based on recommendations from the ASHRAE Handbook [10] and from Nakagawa and Takeuchi [5]. Brass is used as material for the ejector. The three main parts of the ejector are connected by fine screws. Three o-rings, as shown in Fig. 2, are used to prevent refrigerant leakage. The detail drawing of the tested motive nozzle is shown in Fig. 3. In the present study, three motive nozzles having different outlet diameter (Dne) of 2.0, 2.5 and 3.0 mm are investigated. The inlet diameter (Dni), inlet length (Lni), convergent length (Lnc), throat diameter (Dnt) and diver- gent length (Lnd) of all three motive nozzles are 6, 32, 6, 0.9, 20 mm, respectively. Usually, a comparison of the cycle performance can be made by two approaches. The first one is based on internal parameters i.e. evaporating and condensing temperatures. This method requires the different modes to be compared at the same evaporating and condensing temperatures. The second one is based on external parameters such as the inlet temperature and the flow rate of the heat transfer fluid (HTF) (Hoegberg et al. [11], Giuliani et al. [12]). This method allows each mode of operation to operate under the same external conditions. In this paper, the comparison is based on the second method. This method is selected because it is more likely in real life. Water is used as the heat transfer fluid. Hot water acts as a heat source of the evaporator and heat source temperature means temperature of hot water. While cold water acts as a heat sink of the condenser and heat sink temperature means temperature of cold water. According to the experimental conditions, the test runs are done at heat source temperatures ranging between 8 °C and 16 °C while the volume flow rate of hot water is kept constant at 12 LPM. Each value of heat source temperature is tested at varying heat sink temperatures of 26.5, 29.5, 32.5, 35.5 and 38.5 °C. The volume flow rate of cold water is fixed at 14 LPM. These volumetric flow rates of cold water and hot water are employed to prevent water from freezing on the surface of the equipment. The compressor speed is maintained at 450 rpm by controlling the inverter frequency. It should be noted that this speed Dnt Dne Dni Lni Lnc Lnd Fig. 3. Motive nozzle. is appropriate for this experimental set up. This speed is employed after problems were encountered at several different speeds used in previous experiments. It has been found that if compressor speeds of over 450 rpm are used, the pressure in the liquid–vapor separator decreases. This enables the liquid in the separator to become increasingly vaporized and finally result in the increase of the vapor temperature. This high temperature vapor probably causes the compressor to become damaged. Also if compressor speeds of lower than 450 rpm are used, the amount of liquid in the separator gradually increases. Finally, the liquid refrigerant floods the outlet of the separator and flows to the compressor. This results in compressor failure. The water temperatures are kept constant at the required values in both the hot and the cold water tanks. They are then circulated through the condenser and evaporator at constant temperatures and constant volume flow rates by the circulating pumps. 3. Results and discussion Fig. 4 shows a pressure-enthalpy diagram of the two-phase ejector refrigeration cycle for Dne = 2.5 mm, at Tsource = 8 °C and Tsink = 26.50 °C. Fig. 4 is only an example, however the experimental results from other experimental conditions give the same tendency. The cycle is separated into two loops; primary refrigerant loop and secondary refrigerant loop. In the primary refrigerant loop, vapor from the liquid–vapor separator is drawn in the compressor cylinder during its suction stroke and is compressed to pressure p2 and temperature T2 during the compression stroke and delivered out from the compressor at condition 2 passes on to condenser at 2 0 in which cooling water is supplied to remove heat from the vapor. Vapor is therefore first cooled to the saturated temperature at pressure p2 and further removal of heat. Condensation at the high temperature produces a sub-cooled liquid refrigerant at point 3. The high pressure liquid is now further expanded through motive nozzle at point 3 0 . The primary refrigerant will be mixed with the secondary refrigerant at mixing chamber. The mixture will be compressed through diffuser and flow to point 4 and to the liquid–vapor separator. In the secondary refrigerant loop, since high pressure primary refrigerant is supplied to the nozzle inlet and is expanded in the mixing chamber, refrigerant vapor originating from the evaporator at point 6, is entrained with the high velocity refrigerant jet and compressed through mixing chamber into the diffuser at point 4. Vapor refrigerant from the liquid–vapor separator is sucked by compressor while sub-cooled liquid passes on to the inlet of the evaporator at point 5 and absorbs heat from hot water supplied to the evaporator. The outlet of the evaporator appears a point 6. The cycle continues on and on. Motive nozzles used in the present study have different sizes of outlet diameter. This different outlet diameter directly affects the shape of the divergent angle of the motive nozzle. The following results are gained from experimental conditions in which the refrigerant at the entries of the motive nozzle and the evaporator are sub-cooled with temperatures of 0.1–3.5 °C and 0.1–1.1 °C, respectively, while the refrigerant at the inlet of the compressor is superheated with the temperature of 2.0–4.5 °C. The experiment yields similar variations of most variables affecting the performance of the cycle, with significant differences in certain conditions. However, the variations of variables tested with this range of outlet diameter are not favorably obvious. Fig. 5 shows the variation of the primary mass flow rate with heat sink temperature from using the various sizes of motive nozzle for the different heat source temperatures of 8, 12 and 16 °C. The graph indicates that an increase or decrease of the heat source temperature does not affect the primary mass flow rate, even though it has direct effect on the increase or decrease of temperature and pressure in the evaporator. This varying pressure has very little effect on the pressure difference between the inlet and the discharge of the motive nozzle. Therefore, the variation of the heat source temperature has no significant effect on the primary mass flow rate. Concerning the variation of the primary mass flow rate with heat sink temperature at heat source temperatures of 8, 12 and 16 °C, as shown in Fig. 5, it is found that the primary mass flow rate tends to increase when the heat sink temperature increases. This is because the temperature and pressure of the condenser increase with increasing heat sink temperature. This higher condenser pressure results in the increase of the pressure at the inlet of the motive nozzle. As a result, the pressure difference between the inlet and the outlet of the motive nozzle also increases which, in turn, 10.0 10.0 Motive Nozzle Dne = 2.5mm. TSource = 8oC Pressure (MPa) TSink = 26.5oC 1.0 2 3 1.0 2' 3' 4 5 1 6 Ideal Actual ne me se 0.1 0.1 150 200 250 300 350 400 450 500 Enthalpy (kJ/kg) Fig. 4. Pressure–enthalpy diagram of the two-phase ejector refrigeration cycle in the present study. Primary Mass Flow Rate (kg/s) .04 .03 Motive Nozzle : Dne = 3.0 mm. Dne = 2.5 mm. Dne = 2.0 mm. TSource = 8 oC TSource =12 oC TSource =16 oC Subcooling at the Inlet : - Motive Nozzle : 0.1-3.5 oC - Evaporator : 0.1-1.1 oC .02 .01 0.00 24 26 28 30 32 34 36 38 40 Heat Sink Temperature (οC) Fig. 5. Comparison of primary mass flow rates of refrigerant at heat source temperatures of 8, 12 and 16 °C. increases the primary mass flow rate. When comparing the primary mass flow rate gained from the three motive nozzles, it is found that all motive nozzles give similar primary mass flow rate. Fig. 6 shows the comparison of the secondary mass flow rate gained from using various sizes of motive nozzle at the heat source temperatures of 8 and 16 °C. The graph shows that the change of the heat source temperature has a small Secondary Mass Flow Rate (kg/s) .04 Subcooling at the Inlet : - Motive Nozzle : 0.1-3.5 oC - Evaporator : 0.1-1.1 oC .03 .02 .01 24 Motive Nozzle : Dne = 3.0 mm. Dne = 2.5 mm. Dne = 2.0 mm. 26 28 30 32 TSource = 8 oC TSource =16 oC 34 36 38 40 Heat Sink Temperature (οC) Fig. 6. Comparison of secondary mass flow rates of refrigerant at heat source temperatures of 8 and 16 °C. effect on the secondary mass flow rate. In addition, the results suggested that the secondary mass flow rate depends mainly on the primary mass flow rate and the pressure at the outlet of the motive nozzle. The comparison of the secondary mass flow rates at Tsource = 8 °C, reveals that motive nozzle having Dne = 3.0 mm produced a slightly higher secondary mass flow rate than the other nozzles, as more clearly evident at high heat sink temperatures. Concerning the changes in the secondary mass flow rate and heat sink temperature when using 3 different sizes of motive nozzle, it is found that the secondary mass flow rate increases when the heat sink temperature increases. This is because the higher heat sink temperature makes the pressure difference between the inlet and the outlet of motive nozzle higher, resulting in a higher velocity of the primary mass flow rate that causes the pressure to drop at the outlet of the motive nozzle. This pressure drop at the outlet of the motive nozzle increases the pressure difference between the outlet of the motive nozzle and the outlet of the evaporator. Hence, the secondary mass flow rate increases accordingly. The recirculation ratio is defined as the ratio between the refrigerant mass flow rate delivered to the evaporator ðm_ s Þ and flow rate of the vaporized refrigerant ðm_ e Þ. Fig. 7 shows the variation of the recirculation ratio with heat sink temperature from using the various sizes of motive nozzle at heat source temperatures of 8 and 16 °C. The result shows that the recirculation ratio decreases with an increase in heat source temperature. This is because the heat source temperature increases with increasing rate of heat transfer at the evaporator, which results in the increasing vaporized mass flow rate, while the secondary mass flow rate changes slightly. Ultimately, the recirculation ratio also increases. The comparison of the recirculation ratio when using motive nozzles at heat source temperatures of 8 and 16 °C as shown in Fig. 7, indicates that motive nozzle having Dne = 3.0 mm produces the higher recirculation ratio than the others. This is because the recirculation ratio is the ratio of the secondary mass flow rate and vaporized mass flow rate in the evaporator obtained from the calculation. The calculation result indicates that the vaporized mass flow rate is lowest when using motive having Dne = 3.0 mm. Considering the change in the recirculation ratio and heat sink temperature gained from the three different sizes of motive nozzle, it is found that the recirculation ratio tends to increase when the heat sink temperature increases. This is due to the ejector behavior. That is because the secondary mass flow rate increases with increasing heat sink temperature, while the vaporized mass flow rate drops. The higher heat sink temperature causes the heat transfer at the evaporator to drop. Fig. 8 shows the variation in the average evaporator pressure as the heat sink temperature changes, from using the various sizes of motive nozzle at heat source temperatures of 8, 12 and 16 °C. The graph indicates that the higher heat source temperature gives higher average evaporator pressure. This is because the change in the heat source temperature directly affects the changes of temperature and pressure in the evaporator. The changes in the average evaporator pressure and heat sink temperature as shown in Fig. 8, indicate that when the heat sink temperature increases, the average evaporator pressure will also increase slightly – even though the increase or decrease of the heat sink temperature does not have a direct effect on the change of pressure in the evaporator. The increase of the average evaporator pressure may result from other causes, such as, the heat transfer 5.0 Recirculation Ratio 4.0 Subcooling at the Inlet : - Motive Nozzle : 0.1-3.5 oC - Evaporator : 0.1-1.1 oC 3.0 2.0 Motive Nozzle : Dne = 3.0 mm. Dne = 2.5 mm. Dne = 2.0 mm. 1.0 0.0 24 26 28 30 32 TSource = 8 oC TSource =16 oC 34 36 38 40 Heat Sink Temperature (οC) Fig. 7. Comparison of recirculation ratio at heat source temperatures of 8 and 16 °C. 0.6 Average Evaporator Pressure (MPa) Superheating at the Compressor Inlet : 2.0-4.5 oC 0.5 0.4 0.3 Motive Nozzle : Dne = 3.0 mm. Dne = 2.5 mm. Dne = 2.0 mm. 0.2 0.1 24 26 28 30 32 TSource = 8 oC TSource =12 oC TSource =16 oC 34 36 38 40 Heat Sink Temperature (οC) Fig. 8. Comparison of average evaporator pressure at heat source temperatures of 8, 12 and 16 °C. from surrounding into the system. When comparing the average evaporator pressures gained from the three different sizes of motive nozzle, it is found that all motive nozzles produce almost the same average evaporator pressure. Fig. 9 shows the relation between the compressor pressure ratio and the heat source temperature from using the various sizes of motive nozzle at the heat sink temperatures of 26.5, 32.5 and 38.5 °C. It is clear that the compressor pressure ratio increases with increasing heat sink tempera- ture. This is because the heat sink temperature has a direct effect on the temperature and pressure in the condenser. When the condenser pressure increases, the pressure at the condenser outlet also increases. This results in the increase of the compressor pressure ratio. The compressor pressure ratio for specific heat source and heat sink temperatures obtained from all motive nozzles is similar. Fig. 10 shows the discharge temperature plotted against heat source temperature for the various sizes of motive nozzle at heat sink temperatures of 26.5, 32.5 and 5.0 Superheating at the Compressor Inlet : 2.0-4.5 oC Compressor Pressure Ratio 4.0 3.0 2.0 Motive Nozzle : Dne = 3.0 mm. Dne = 2.5 mm. Dne = 2.0 mm. 1.0 TSink = 26.5 oC TSink = 32.5 oC TSink = 38.5 oC 0.0 8.0 10.0 12.0 14.0 16.0 ο Heat Source Temperature ( C) Fig. 9. Comparison of compressor pressure ratio at heat sink temperatures of 26.5, 32.5 and 38.5 °C. 80 Superheating at the Compressor Inlet : 2.0-4.5 oC Discharge Temperature (oC) 70 60 50 40 Motive Nozzle : Dne = 3.0 mm. Dne = 2.5 mm. Dne = 2.0 mm. 30 TSink = 26.5 oC TSink = 32.5 oC TSink = 38.5 oC 20 8.0 10.0 12.0 14.0 16.0 ο Heat Source Temperature ( C) Fig. 10. Comparison of discharge temperature at heat sink temperatures of 26.5, 32.5 and 38.5 °C. 38.5 °C. The plot shows that the increase of heat sink temperature makes the discharge temperature rise accordingly. This is because when the heat sink temperature increases, the compressor pressure ratio will also increase and, consequently, the compressor temperature ratio defined as the ratio between the temperature at the compressor outlet and the temperature at the compressor inlet, will increase accordingly. The result from this figure indicates that the discharge temperature tends to decrease when the heat source temperature increases. The discharge temperatures gained from all motive nozzles for specific heat source and heat sink temperatures are similar. The cooling capacity can be calculated according to the following equation: Qevap ¼ m_ hw cp;hw ðT hw;in T hw;out Þ where m_ hw is the mass flow rate of hot water (kg/s), cp, hw is the specific heat at constant pressure of the hot water (kJ/ kg k), Thw, in is the hot water temperature at the inlet of the evaporator (°C), Thw, out is the hot water temperature at the outlet of the evaporator (°C). 4.0 Superheating at the Compressor Inlet : 2.0-4.5 oC Cooling Capacity (kW) 3.0 2.0 Motive Nozzle : Dne = 3.0 mm. Dne = 2.5 mm. Dne = 2.0 mm. 1.0 TSink = 26.5 oC TSink = 38.5 oC 0.0 8.0 10.0 12.0 14.0 16.0 Heat Source Temperature (οC) Fig. 11. Comparison of cooling capacity at heat sink temperatures of 26.5 and 38.5 °C. Fig. 11 shows comparison of the cooling capacity obtained from all motive nozzles at heat sink temperatures of 26.5 and 38.5 °C. It can be clearly seen that the cooling capacity decreases with increasing heat sink temperature. As a consequence of ejector operation, the higher heat sink temperature causes the temperature difference between the cold water from the heat sink and the refrigerant from the condenser to decrease. As a result, the heat transfer rate of the condenser decreases accordingly. Considering the energy conservation, it is found that when the heat transfer rate of the condenser decreases, the heat transfer rate of the evaporator will also decrease accordingly. The changes in the cooling capacity and heat source temperature as shown in Fig. 11, indicate that the cooling capacity increases as the heat source temperature increases. The change of the heat source temperature is similar to the change in the cooling load of the system. When the temperature of the hot water from the heat source increases, the heat absorption of the refrigerant in the evaporator also increases. The amount of heat absorbed by the refrigerant is actually the average heat transfer rate of the evaporator, which equals the cooling capacity of the system. The comparison of the cooling capacity gained from using the 3 different outlet diameter of motive nozzle 7.0 Superheating at the Compressor Inlet : 2.0-4.5 oC Coefficient of Performance (COP) 6.0 5.0 4.0 3.0 Motive Nozzle : Dne = 3.0 mm. Dne = 2.5 mm. Dne = 2.0 mm. 2.0 1.0 TSink = 26.5 oC TSink = 32.5 oC TSink = 38.5 oC 0.0 8.0 10.0 12.0 14.0 16.0 Heat Source Temperature (οC) Fig. 12. Comparison of coefficient of performance at heat sink temperatures of 26.5, 32.5 and 38.5 °C. reveals that there is no significant effect on the cooling capacity. The system COP is defined as the ratio between the cooling capacity and the electrical power supplied to the compressor and can be written as COP ¼ Qevap W comp where Wcomp is the electrical power supplied to the compressor (kW). This electrical power is directly obtained from the buit-in function of the inverter. Fig. 12 shows the variation of the system’s COP versus heat source temperature from using the various sizes of motive nozzle at heat sink temperatures of 26.5, 32.5 and 38.5 °C. It can be clearly seen that the COP decreases as the heat sink temperature increases. This is because when the heat sink temperature increases, the cooling capacity of the system decreases, while the compressor pressure ratio increases, resulting in an increase of electrical power input of the compressor. Ultimately, this results in the decrease of the COP of the system. Comparison of the system’s COP, at heat sink temperature of 26.5, 32.5 and 38.5 °C, all motive nozzles tend to give similar COP. 4. Conclusions Variables affecting performance and varying directly with the heat sink temperature include the primary mass flow rate, secondary mass flow rate, recirculation ratio, compressor pressure ratio, and discharge temperature. On the other hand, the cooling capacity varies inversely with the heat sink temperature while the average evaporator pressure varies only a little and tends to vary directly. Concerning the effect of the heat source temperature on the variation of variables affecting performance, the results are found to be contrary with the effect of the heat sink temperature, with the exception of the average evaporator pressure which varies directly. On the other hand, the primary mass flow rate and the secondary mass flow rate tend to be slightly increased as the heat source temperature increases. The use of motive nozzles having different outlet diameters in the range of 2.0–3.0 mm yields insignificant effects on the system performance. However, although the ejector cycle has higher performance over the standard cycle, some disadvantage should be considered e.g. high refrigerant charge, high refrigerant flow, piping insulation and installation cost. Acknowledgements The authors would like to express their appreciation to the Thailand Research Fund (TRF) for providing financial support in this study. References [1] A.A. Kornhauser, The use of an ejector as a refrigerant expander, in: Proceedings of the 1990 USNC/IIR-Purdue Refrigeration Conference, 1990; 10–19. [2] G.S. Harrell, A.A. Kornhauser, Performance tests of a two-phase ejector, in: Proceedings of the 30th Intersociety Energy Conversion Engineering Conference, Orlando, FL, 1995; 49–53. [3] P. Menegay A.A. Kornhauser, Improvements to the ejector expansion refrigeration cycle, in: Proceedings of the 31th Intersociety Energy Conversion Engineering Conference, Washington DC, 1996; 702-6. [4] P.A. Domanski, Theoretical evaluation of the vapor compression cycle with a liquid-line/suction-line heat exchanger, economizer, and ejector. Nistir-5606, National Institute of Standards and Technology, March, 1995. [5] M. Nakagawa, H. Takeuchi, Performance of two-phase ejector in refrigeration cycle, in: Proceedings of the Third International Conference on Multiphase Flow. Lyon. France, Jun. 8–12, 1998; 1-8. [6] S. Disawas, S. Wongwises, Experimental investigation on the performance of the refrigeration cycle using a two-phase ejector as an expansion device, Int. J. Refrigeration 27 (6) (2004) 587–594. [7] S. Wongwises, S. Disawas, Performance of the two-phase ejector expansion refrigeration cycle, Int. J. Heat Mass Transf. 48 (2005) 4282–4286. [8] R.E. Henry, H.K. Fauske, The two-phase critical flow of onecomponent mixtures in nozzles, orifices, and short tubes. ASME Trans. J. Heat Transf. May, 1971; 179–87. [9] S.A. Sherif, W.E. Lear, J.M. Steadham, P.L. Hunt, J.B. Holladay, Analysis and modeling of a two-phase jet pump of a thermal management system for aerospace applications, Int. J. Mech. Sci. 42 (2000) 185–198. [10] ASHRAE, ASHRAE Handbook – Guide and Data Book. American Society of Heating, Refrigerating and Air Conditioning Engineering. 1969; Chapter 13, 151–58. [11] M. Hoegberg, L. Vamling, T. Berntsson, Calculation methods for comparing the performance of pure and mixed working fluids in heat pump applications, Int. J. Refrigeration 16 (6) (1993) 403–413. [12] G. Giuliani, N.J. Hewitt, F. Marchesi Donati, F. Polonara, Composition shift in liquid-recirculation refrigeration systems: an experimental investigation for the pure fluid R134a and the mixture R32/ 134a, Int. J. Refrigeration 22 (6) (1999) 486–498.