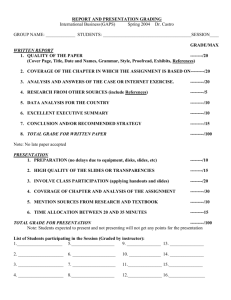

delay to projects – cause, effect and measures to reduce / eliminate

advertisement