11Sep_Harvey - Calhoun: The NPS Institutional Archive

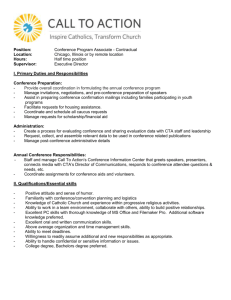

advertisement