KSA College Graduate E

advertisement

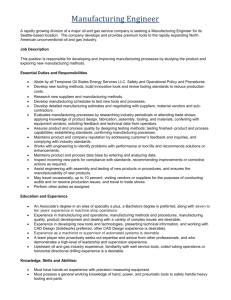

APRIL 2014 Attention KSA Engineering Students! Kingdom of Saudi Arabia Engineering Fellowship Program The Boeing Company is the world’s largest aerospace company and leading manufacturer of commercial jetliners and defense, space, and security systems. KSA Engineering Fellowship Program Overview Candidates must meet program requirements: The KSA Engineering Fellowship Program provides an opportunity of a lifetime for individuals who have received a United States education. This program provides an opportunity to train in the United States then be given the opportunity to work for Boeing in KSA. Selected individuals will receive U.S. training which includes: Boeing work experience, practical on-the-job training, and engineering/platformspecific classroom experiences for approximately 9-12 months in the United States. Available positions will be a part of a world-class engineering organization working for the Boeing Defense, Space & Security (BDS) business. The training statement of work will support the F-15 SA platform at the BDS headquarters in Saint Louis, Missouri. Positions available for 2014*: Manufacturing Engineer (3) Tooling Engineer (2) Industrial Engineer (3) Electrical Engineer (2) • Recent U.S. university graduate (within 12 months prior to the program start date) * Position description on following page • Bachelors or advanced degree in an accredited course of study: Engineering Management, Industrial, Mechanical, Manufacturing, Electrical or Aero Engineering • High academic achievement (3.0 GPA minimum) • Excellent English communication skills (verbal and written) • Leadership, interpersonal, and teamwork skills • Available and authorized to work full-time in U.S. (e.g., under an F-1 visa) for the 9-12 month duration of the program • Desire to return to and work in KSA; future positions will be available working for a local Boeing entity in KSA (multiple locations within the Kingdom) upon completion of the U.S. program • Must also be authorized to work in KSA • Qualify for a U.S. export license for the duration of the program (sponsorship is company responsibility) • Candidates will travel to KSA for a business trip in the first month of assignment • Candidates must satisfy all contingences for these positions How to apply: Submit your resume (in a .docx format) to KSACollegeGraduateProgram@Boeing.com. Please include your graduation date (or anticipated) and position(s) you are applying for. Opportunities are a paid internship with relocation, housing assistance and benefits. Deadline to submit resume is May 9, 2014. APRIL 2014 Position Descriptions Manufacturing and Tooling Engineering (Mechanical, Manufacturing, or Aero Engineering degrees) VOL 1 ISSUE 1 Program Engineers in the discipline of Define/Operations-Integration are primarily assigned to develop and coordinate Manufacturing and Tooling Plans and implement Supply Chain considerations. They are usually assigned these tasks early in the concept definition phase of a program. They bring their knowledge and skills to the an Integrated Product Team (IPT) to influence the design such that it is compatible with current manufacturing technologies/capabilities and can be manufactured with a minimum of engineering changes and achieve an optimum level of quality. Manufacturing Engineers work alongside IPT team members applying their education, manufacturing process knowledge, and experience to influence decisions regarding materials, material properties, and early concept definition. They accomplish this by initiating and analyzing conceptual design and build process options, completing producibility and variation analysis, and introducing pertinent engineering data that needs to be considered as product definition matures. A major responsibility of Manufacturing Engineers is creation, coordination, and optimization of the program architecture for build (manufacturing & tooling plans). Additional job duties include creating & updating Work Instructions (2D & 3D) for Production, coordinating changes, etc. Tool Engineers work alongside IPT team members applying their education, tooling & manufacturing process knowledge and experience to influence decisions regarding materials, material properties, and early concept definition. They accomplish this by initiating conceptual tool designs that support build process options, by participating in or completing producibility and variation analysis, as well as introducing pertinent engineering data that needs to be considered as product definition matures. A major responsibility of Tool Engineers is creation, coordination, and optimization of the Special Tooling that supports the production build requirements of the manufacturing & tooling plans. Electrical Engineering (Electrical Engineering Degree) Diagnostic Engineering is a unique skill set of Electrical / Electronic Engineering where the engineer performs multiple tasks in order to determine the operational status of various types of electronic equipment. In this position, the engineer will analyze maintenance/diagnostic data produced by either the Built In Test (BIT) of the avionics itself or the maintenance data produced by the maintainer while troubleshooting and maintaining avionic equipment. As part of this process, the Diagnostic Engineer will determine if the diagnostic system is performing as designed or if improvements are required. Test Equipment Engineering is an Electrical / Electronic skill set whereby the engineer employs their knowledge of circuit theory and methodologies on how to test that circuit in order to verify the operational status of the avionic design. In this position, the engineer will work with automatic test equipment and develop test routines to meet fault detection and component isolation requirements. These positions require proactive individuals to participate on multi-disciplined teams supporting multiple weapon systems. The job responsibilities include: assist senior engineering in providing the expertise necessary to specify the requirements and analysis of new and modified weapon systems for supportability, BIT effectiveness, and Design for Testability. Other responsibilities include: assist senior engineering in enforcement of diagnostic design, support & testing requirements and customer/supplier design specifications as required for the subsystem, box, and circuit card levels. Industrial Engineering (Industrial Engineering, Engineering Management or Mechanical Engineering degrees) Applies basic Industrial Engineering concepts, techniques, analysis and decision tools to promote and implement changes in manufacturing, engineering and service operations. Develops models, data bases and spreadsheets to analyze data (e.g., statistics, operations research, engineering economics), and provide summary analysis and metrics as directed by higher level employees for consultation to customers (e.g., management, departments, suppliers). Applies basic industrial engineering techniques and concepts to product and process design teams throughout all phases of product lifecycle, resulting in a robust product design and work statement that meets program requirements. Researches, designs, develops, improves and implements processes as directed to enhance schedule performance, lower cost and improve quality, through the application of Lean and other Industrial Engineering concepts for large-scale systems integration and asset utilization. Utilizes engineering methods (e.g., mathematical models, simulation, statistics) to assist in developing optimal process designs and efficient utilization of resources (e.g., facilities, personnel, materials, equipment) in the creation and validation of products. Analyzes and supports the design of the value stream, including capability, capacity (e.g., make/buy, supplier selection, risk analysis, supplier performance), throughput, work flow and logistics (e.g., critical path, lead time, transportation, factory layout).