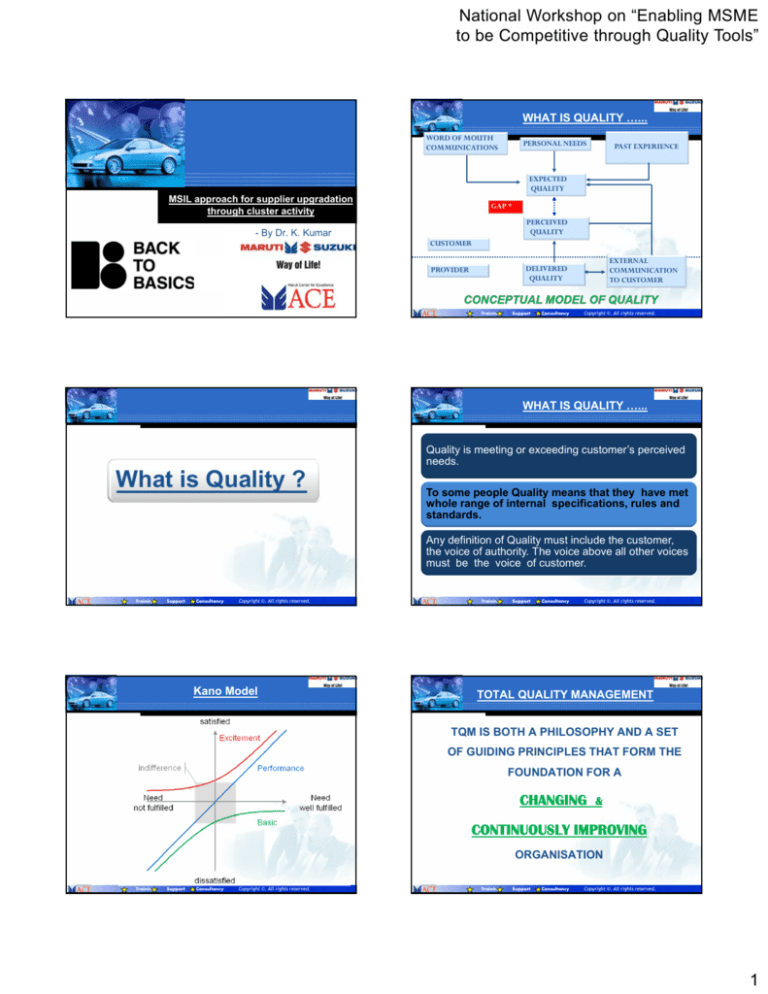

National Workshop on “Enabling MSME

to be Competitive through Quality Tools”

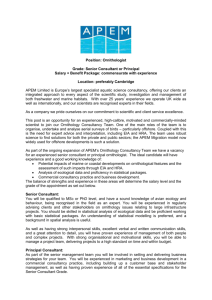

WHAT IS QUALITY …...

WORD OF MOUTH

COMMUNICATIONS

PERSONAL NEEDS

PAST EXPERIENCE

EXPECTED

QUALITY

MSIL approach for supplier upgradation

through cluster activity

GAP *

PERCEIVED

QUALITY

- By Dr. K. Kumar

CUSTOMER

EXTERNAL

COMMUNICATION

TO CUSTOMER

DELIVERED

QUALITY

PROVIDER

Training

Support

Consultancy

Copyright ©. All rights reserved.

WHAT IS QUALITY …...

Quality is meeting or exceeding customer’s perceived

needs.

What is Quality ?

To some people Quality means that they have met

whole range of internal specifications, rules and

standards.

Any definition of Quality must include the customer,

the voice of authority. The voice above all other voices

must be the voice of customer.

Training

Support

Consultancy

Copyright ©. All rights reserved.

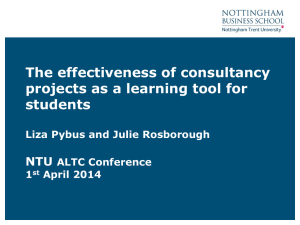

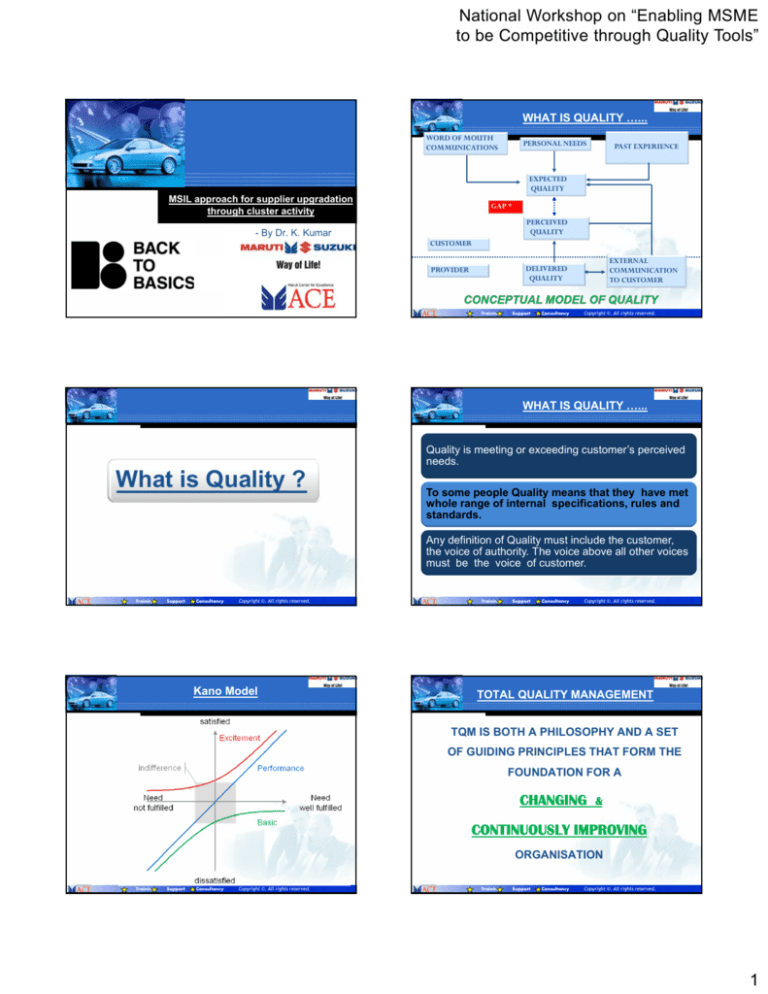

Kano Model

Training

Support

Consultancy

Copyright ©. All rights reserved.

TOTAL QUALITY MANAGEMENT

TQM IS BOTH A PHILOSOPHY AND A SET

OF GUIDING PRINCIPLES THAT FORM THE

FOUNDATION FOR A

CHANGING

&

CONTINUOUSLY IMPROVING

ORGANISATION

6

Training

Support

Consultancy

Copyright ©. All rights reserved.

Training

Support

Consultancy

Copyright ©. All rights reserved.

1

National Workshop on “Enabling MSME

to be Competitive through Quality Tools”

Principle of total quality

ELEMENTS OF CUSTOMER SATISFACTION

Principle 1

• Proactively and systematically understand current and

PRODUCT DESIGN

QUALITY

CONFORMANCE

COST EFFECTIVE

COST

WORLD CLASS

QUALITY FOR

CORPORATE

SURVIVAL

PRICE EFFECTIVE

RIGHT PLACE

RIGHT TIME

DELIVERY

RIGHT AMOUNT

ASSURANCE OF QUALITY

SERVICE

FULL

CUSTOMER

SATISFACTION

/ DELIGHT

Proactively Companies must anticipate

customer’s needs.

•

IN USE

SAFETY

future customer needs (External and Internal)

• Customer complaints analysis is critical, it can only be

done after the complaint is resolved.

IN PRODUCTION

MORALE

EVERYONE CARES

10

Living Our CI Values

Principle 2

My input

My

Supplier

I Am

Responsible

for

Quality

As a

Good Customer

Requirement

And

feedback

I will

2)

3)

Agree on and

document my

requirements with

my supplier

Return defective

inputs to my supplier

promptly and

tactfully

Feed back input

quality data to my

supplier

My output

My

Customer

As a

Good Process

Owner or User

As a

Good Supplier

I Will:

1)

1)

Systematically it must be ensured that the process

used to resolve the

complaints is valid, objective

and statistically reliable.

2)

3)

Learn and apply

the tools of

quality and

teach others.

Continuously

improve my

process-reduce

defects, cycle

time and know

benchmarks

Document and

display my

process, defect

levels, and CI

projects

I Will:

1)

2)

3)

Requirement

And

feedback

Proactively and systematically measure the customer’s

perception of how well your organization and your direct

competitors satisfy these needs.

Robert Galvin, former chairman and CEO of Motorola

cited,

“Only by measuring something it can be truly known.”

In order to be useful, customer satisfaction measurements

must be both objective and reliable.

To ensure objectivity, a number of companies use a third

party to assess customer satisfaction.

Reliability means that for any situation the measurement

process will yield the same, or nearly the same result.

Understand my

customer

requirements and

agree on

and

document my

deliverables

Reduce defects

and variations in

my output

Measure my

output quality

from my

customer’s

perspective

11

Principle 3

Focus efforts on improving the processes or methods that

satisfy customer needs. Better financial results such as cost

reduction and higher profits are the outcome of process

improvements.

Total Quality approach would be to improve the process by

streamlining it, reducing errors, shortening process, cycle time

and eliminating activities that don’t affect Customer

Satisfaction.

To improve quality, reduce process variation.

Variation is present in all activities and processes. Although

they might be made or delivered according to the same design,

there will be differences in parts, products and services. In

many instances, variation is within an acceptable tolerance

band.

Principles of Quality

9

12

2

National Workshop on “Enabling MSME

to be Competitive through Quality Tools”

Principle 5

Variation

•Develop robust design for products and processes.

•Robust design are not sensitive to variations of

production processes, components, raw materials,

and customer usage.

•The traditional engineering approach is to design a

target (target value, target function, target region)

then reduce variation around the target.

•The new approach developed by Genichi Taguchi,

is to design for robust function, then adjust the

target.

13

16

Taguchi Loss Function

Principle 4

causes of process variation are

ever present and vary randomly within some

statistical distribution. Process is stable when

common causes are present.

•Special causes of variation are those outside

the common causes that are ever present. The

variation is due to specific assignable causes

that are non random occurrences. Special

causes are sporadic and not predictable.

LSL

USL

A

L = k (y – T)2

0

y

T-

L

Loss ($)

•Common

Loss ($)

L

T

Step function

T+

USL

LSL

T = Target

k = Quality Loss Function

y

T-

A stable process in control (Natural or common cause)

Upper

process

limit

Customer

Satisfaction

T

T+

Quadratic function

17

Principle 6

Variation

Mean

Lower

process

limit

Time

An unstable process out of control(Special Cause)

Upper

process

limit

Customer

Satisfaction

y = Performance Characteristic

A

0

14

L = Cost Incurred as quality

Deviates from the target

Mean

Lower

process

limit

•Use the scientific method for solving problems

and improving processes.

•This means that organizations must manage by

fact and not by assertion. Dr. W. Edwards Deming

has said

“In God we trust, but from all others we demand

data.”

•Managing by fact really means applying the

scientific process, which is described very clearly

by the Plan-Do-Check-Act (PDCA) Cycle

Time

18

3

National Workshop on “Enabling MSME

to be Competitive through Quality Tools”

PDCA Cycle

Objective

Data

Cont.

Inside & Outside

Company

Never pass on known or suspected bad quality

Abroad

Method

the next person in the process.

Education

Follow 3-NAI activity

Implementation

to

Do not receive

Consumer

Do not make

Checking

Do not send defects to the next process

Corrective

action

Product

19

22

Principle 7

When there are problems, and expectations haven’t been

met, look to the system. Don’t blame people.

Instead of finger pointing, management should focus on

the system. Instead of asking “Who did it?” or “Who didn’t do

it.?” Management should ask “What is wrong with the

system?”

Paradoxically the whole system is controlled by

management and not by people who work inside the system.

Emphasize prevention instead of detection. Inspection does

not add value and it doesn’t improve quality. It only helps to

ensure that what goes to the customers is okay.

Biggest Challenge

•How to Maintain the Market Share & How many varieties of products are

introduced in the Market every Year?

•To improve the Quality of the Products in terms of Quality, Cost &

Delivery.

For improving Quality what should we do?

20

Training

Principle 8

Support

Consultancy

Copyright ©. All rights reserved.

QC 7 Step Solving approach

The ultimate way to ensure quality, however, is to

design processes so that regardless of variation of

process control parameters the output is optimal or nearly

optimal. Such processes are said to be robust designs. A

related concept is the principle of Fool Proofing, or

poka - yoke in Japanese.

QC 7 steps Procedure is the basic procedure for solving

problems scientifically, rationally & effectively.

It is the fundamental Problem solving strategy which

allows to solve the problems rationally & scientifically.

If we want to achieve EFFECTIVE improvement we have

Put Quality ahead of quantity.

to know the rules of the game i.e. QC 7 Steps

It means:- Consistent Quality standards

Procedure.

The secret of our problem solving is to know the

21

Procedure & act in accordance with it.

Training

Support

Consultancy

Copyright ©. All rights reserved.

4

National Workshop on “Enabling MSME

to be Competitive through Quality Tools”

QC 7 Step Problem Solving Formula

QC 7 Step Formulae

The conventional method is based on trial & error.

Figure‐1

a.

b.

Table‐1 Cont.

Step

No.

Basic Steps

Action Item

Expose Problem

Expose Problem

•Grasp Problem

•Set Target

•Identify

gap

between existing

situation & Target

Experience, Intuition,

nerve, Inspiration

Analyze Causes

•Investigate Causes

6

Check Results

•Check results of Countermeasures

•Compare results with Target

•Identify Tangible & Intangible benefits

Implement CounterMeasure

•Plan

Countermeasures

•Implement

Countermeasure

•Institutionalize

7

Implement CounterMeasure

Standardize & Establish

Control

Standardize

•Establish new standards & revise old ones.

•Decide methods of control

Establish Control

•Familiarize relevant people with the methods.

•Educate those responsible.

•Verify that benefits are being maintained.

Conventional Problem Solving approach

Training

QC Problem Solving approach

Support

5

Consider & Implement

Countermeasures

Consider Countermeasures

•Propose the ideas for Countermeasures

•Discuss how put Countermeasures into effect.

•Check details of the Countermeasures

Implement Countermeasures

•Plan how to implement Counter Measures

•Implement Countermeasures

Copyright ©. All rights reserved.

Consultancy

Training

Support

Consultancy

Copyright ©. All rights reserved.

Procedure for Problem Solving

QC Problem Solving approach Figure‐2

In the QC Seven Step Procedure the following points are

important:

1.

Problem

arises

Identify its

Causes

Act against

the Causes

Understand the situation & set targets: This

would mean analyzing data on the existing & past

situation & then decide the target. Fig. 3 shows the

procedure to calculate the targets

Figure‐3

Symptom

Disappears

Problem

Solved

In case of QC Problem Solving approach, the problem really has been Solved; this

is true Problem Solving

Training

Support

Consultancy

Copyright ©. All rights reserved.

Baseline

117642

Entitlement

86013

Difference

31629

70% of Diff.

22140

Target @70% of

Entitlement

95502

Training

QC 7 Step Problem Solving Formula

Support

Consultancy

Copyright ©. All rights reserved.

Procedure for Problem Solving

Table‐1

Step

No.

2.

Basic Steps

Analysis of the causes : Late Dr. Kaoru Ishikawa,

Action Item

the father of Japanese Quality Control, wanted it to

1

Select Topic

•Identify Problem

•Decide Topic

2

Understand the

situation & Select

Target.

Understanding Situation

•Collect Data

•Decide characteristic to attack

•Decide Target

3

Plan Activities.

•Decide what to do

•Decide Schedule, division of responsibility etc.

4

Analyze Causes

•Check present values of Characteristic

•List Possible Causes

•Analyze Causes

•Decide items to tackle.

Training

Support

Consultancy

be renamed as “analyze the process”. But ultimately

Copyright ©. All rights reserved.

in JUSE 7 step procedure analyze the causes was

retained & is widely used.

3.

Countermeasures: After the analysis of the Causes,

the team proceeds to take the countermeasures to

prevent the occurrence of the defects.

Cont…

Training

Support

Consultancy

Copyright ©. All rights reserved.

5

National Workshop on “Enabling MSME

to be Competitive through Quality Tools”

Procedure for Problem Solving

Basic 7 QC Tools

Checksheet

Run Chart

Pareto Chart

4. Standardize & Establish the Control : In the Past

this step was known as “Apply the Brakes” i.e.

prevent any back sliding & establish the permanent

Countermeasure. Failing to check the effect of

Control Chart

Countermeasure is like omitting the touch up after

Histogram

Painting. This would need establishing the new

standards or revising the old standards. Familiarize

Scatter Plot

Fishbone Diagram

people with the new standards & verify that the

benefits are being maintained.

Training

Support

Consultancy

Copyright ©. All rights reserved.

Training

Figure‐4

Consultancy

Copyright ©. All rights reserved.

Why-Why Analysis

Procedure for Problem Solving

5. Target Control: While fixing the targets & the time

limits for the achievements following key points are

important.

What control Characteristic are to be taken up for

study.

By When the study will be completed.

By How much such as reduce the defect at the

Quality gate by 30%.

Support

Originally developed by Sakichi Toyoda.

Later

used

within

Toyota

Motor

Corporation during the evolution of their

manufacturing methodologies.

The architect of the Toyota Production

System, Taiichi Ohno, described the 5

whys method as "the basis of Toyota's

scientific approach by repeating why five

Taiichi Ohno

times, the nature of the problem as well as

its solution becomes clear

Training

Support

Consultancy

Copyright ©. All rights reserved.

Training

Support

Consultancy

Copyright ©. All rights reserved.

Problem Solving: 5 Whys

TOOLS & TECHNIQUES

USED FOR PROBLEM

SOLVING

AT

MACE

This method of

problem

solving

simply

involves

asking “Why” a

number of times

(typically five times

is enough) until the

root cause of a

problem

is

determined .

36

Training

Support

Consultancy

Copyright ©. All rights reserved.

Training

Support

Consultancy

Copyright ©. All rights reserved.

6

National Workshop on “Enabling MSME

to be Competitive through Quality Tools”

Shainin Techniques for Problem

Solving

Why -Why Analysis at Toyota

Why 2?

Why 3?

Why 4?

Why 5?

Why there is a puddle of oil on the Shop Floor?

• Because Machine is Leaking Oil

Product Process Search

Why the Machine is Leaking oil?

• Because Gasket has deteriorated

Why Gasket has deteriorated?

• Because we bought the Gasket made of inferior

Material.

Why did we buy a Gasket of Inferior Material?

Because we got a Fair deal on those Gaskets

Support

Snorkel Position

Disassembly/Asse

mbly

X-BOB

X-WOW

Parameter Range

0to 1/2"

Initial

113

86

Bag no.

1

2

3

1/2 B

1/2 B

1/2 B

Ist

115

84

4

5

6

7

8

9

10

11

1/2 B

1/2 B

1/4 B

1/4 B

1/4 B

0G

0G

0G

12

13

14

0G

0G

0G

15

16

End Counts

0G

0G

8+ 8 = 16

Support

Range

4

2

D( Diff of Medians

= ( 113 -85 ) = 28

d ( Avg. of

Ranges )

= ( 4+2 )/2 = 3

219

217

C

212

210

-40

-30

-20

-10

0

Sequence

Support

Consultancy

Copyright ©. All rights reserved.

Attributes for World Class

Dorian Shainin

Copyright ©. All rights reserved.

Consultancy

85

-50

Training

S.NO.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

Training

85

113

223

20

Shainin Techniques for Problem

Solving

Dorian Shainin (September 26, 1914 –

January 7, 2000) was an influential

American quality consultant, aeronautics

engineer, author

Known for his contributions in the fields

of industrial problem solving, product

reliability, and quality engineering,

particularly the creation and

development of the “Red X” concept

111

225

B

10

Copyright ©. All rights reserved.

Consultancy

IInd

Median

B Vs C

Component Search

Why we purchased the Material at Fair Price when the

Quality of the Gasket was not Good ?

a) Because the Purchasing agent gets evaluated on

short term Cost Savings

Training

Modified Component Search

Process Parameter

Temp

Why 1?

ITEM

Safety :

5 S – Score

Quality :

Supply to Customer

Customer Line Stops

Inventory Turns:

Change over time

OEE (Overall Equipment Efficiency)

VA to Employee cost

VSM : Value stream mapping

Cost

Absenteeism (Unauthorized)

Direct to Indirect manpower

Kaizens / employee

New Product Development

Training Hours / Emp / Year

Training

Support

Consultancy

TARGET

Zero Accidents

90% min.

3.4 ppm

2 hourly basis

Zero

Min 50

< 10 min.

85 - 90 %

5

25%

50% less

0%

60 : 40

24/emp/year

At 50% less time and

Cost

> 5 % of working hrs

Copyright ©. All rights reserved.

Shainin Techniques for Problem

Solving

Component Search

Disassembly/Asse

mbly

X-BOB

X-WOW

Initial

113

86

Paired Comparison

S.No.

Surface Finish

Status Of the

Pump

1

65

Bad

Ist

115

84

2

64

Bad

IInd

111

85

3

61

Bad

Median

113

85

4

58

Bad

4

2

Range

D( Diff of Medians

d ( Avg. of

Ranges )

5

51

Bad

= ( 113 -85 ) = 28

6

48

Bad

= ( 4+2 )/2 = 3

7

47

Bad

8

45

Bad

Component Search

-50

-40

9

32

Good

10

32

Good

11

28

Good

12

24

Good

13

22

Good

14

22

Good

15

21

Good

16

19

Good

CLUSTER APPROACH

AT

MACE

-30

Temp

-20

-10

0

Sequence

10

20

Training

Support

Consultancy

Copyright ©. All rights reserved.

Training

Support

Consultancy

Copyright ©. All rights reserved.

7

National Workshop on “Enabling MSME

to be Competitive through Quality Tools”

•TPM Cluster

•Certified Quality Engineer

•Six Sigma Black Belts.

•Benchmarking Visits.

•Horizontal Deployment of Cluster Activity

through Tier-2.

MODEL

F

R

WORLD CLASS

•Complete 5-S

•Up-gradation through advance Quality Tools

•Hoshin-Kanri (MFO).

•Autonomous Maintenance; OEE

•Yield Improvement

•Implementation of 8 Pillars Check sheet

•Training on advance tools like DOE, DMAIC &

OEE

Phase 3

•TEI through SSQC activities.

•Single Piece Flow using Model Line; identifying

Lean Manufacturing Projects (MPS) based on

Customer Requirements.

•Inventory Turns Ratio Management

•Energy Consumption Management

•Cost of Poor Quality

•Initial Supply Control

•Value added per employee cost (VAPCO)

•Training on SSQC, MPS, EMS, QMS, NPD.

•Capturing Customer Voice

•1-S,2-S and Visualization

•Customer Concern (QCD) through why-why

Analysis.

•Red Bin Analysis using basic QC Tools

•Daily Work Management for Target Monitoring.

•Monthly Performance Review at Gemba &

Collaborative Learning

•5 New Kaizen/month/vendor.

•Training on 5S, VUD, 7 QC tools, CAPA

Phase 4

PHASE 2

CLUSTER MEETING IN PROGRESS

PHASE 1

Training

undergo a common training session and get hand held

experience.

Individual attention is given to all cluster members & all

queries during the session are answered.

Training

Support

Consultancy

Consultancy

Copyright ©. All rights reserved.

EXACTNESS

Concept of Cluster

A group of 5 to 10 vendors ( non-competing) get together to

Support

The first step in the improvement journey is Exactness. This

involves three parameters:

Exactness of Process: The vendor must ensure that the

process is being followed exactly as per the standards, as

per written down instructions. To achieve this the vendor

must employ check points in Daily Work management.

Copyright ©. All rights reserved.

Training

Advantages of Cluster

Support

Consultancy

Copyright ©. All rights reserved.

EXACTNESS

Exactness of Measurement:

This image cannot currently be display ed.

Lower Cost.

Group discussions & sharing of ideas.

Competitiveness.

Learning from one another.

Exposure to best practices.

Learning in a team.

Exposure to benchmarking.

Improved motivation.

Training

Support

Consultancy

Copyright ©. All rights reserved.

Any process is as good as its measurement. The vendor

must ensure that there is a control plan for all the

instruments & measuring gauges; periodic calibrations

are carried out as per the plan & all instruments /gauges

are kept in good working condition.

Training

Support

Consultancy

Copyright ©. All rights reserved.

8

National Workshop on “Enabling MSME

to be Competitive through Quality Tools”

Practical Problem Solving Process

TEAM ORIENTED PROBLEM SOLVING [ TOPS ]

Kaizen Competition at CII – Confederation of Indian

Industries

1. Initial Problem Perception

(Large , Vague, Complicated Problem)

2. Clarify the Problem

Grasp the

Situation

3. The “ Real “ Problem

Basic Cause and Effect

Investigation

4. POC

Direct Cause

Cause

Cause

Cause

Cause

Why ?

Why ?

5 Why ?Investigation

Of Root Cause

Funnel

Approach

Why ?

Why ?

Why ?

Root Cause

5. Countermeasure

6. Evaluate

Training

Support

Consultancy

7. Standardize

Copyright ©. All rights reserved.

Training

Manufacturing activities .

Every Year a competition amongst the Tier – 2 vendors is

held at MSIL where each vendors make a presentation

about the QC & Lean Manufacturing activities [ MPS ].

In order to motivate the vendors, awards are given through

MSIL, the parent organization .

We also encourage our Tier – 2 vendors to participate in

National Competitions to understand the best practices.

Training

Support

Consultancy

Copyright ©. All rights reserved.

Support

Consultancy

Copyright ©. All rights reserved.

Copyright ©. All rights reserved.

Total no. of Tier 2 clusters

Total no. of Tier 2 vendors covered

:

:

19

150

Measure

2004 - 05

2010 - 11

2011 – 12

Improvement

Rejection

ppm

10933

2695

1617

85 %

No. of defects

per month

432

263

159

63 %

Training

Support

Consultancy

Copyright ©. All rights reserved.

MPS for Tier-2 vendors

Implementation status

TEAM ORIENTED PROBLEM SOLVING [ TOPS ]

Quality Circle Competition in progress

Training

Consultancy

Result of Cluster approach

initiated by MACE

TEAM ORIENTED PROBLEM SOLVING

[ TOPS ]

We encourage Tier – 2 vendors in Quality Circle & Lean

Support

Training

Support

Consultancy

Copyright ©. All rights reserved.

9

National Workshop on “Enabling MSME

to be Competitive through Quality Tools”

QC Activity for Tier-2 vendors

MACE Quality Circle Convention

QC Projects completed in 2011-12 till Oct’11

As a part of Quality month celebration,Tier-2 Quality circle competition was

organized at MACE on 26th Nov’11.

Each of the cluster member held the competition at their end to select the best QC

Circle at their end for Competition in MACE.

A Total of 12 Quality Circles from 12 Tier-2 Clusters participated in this

competition.

The results of competition were as follow:

Winner

Training

Support

Consultancy

Copyright ©. All rights reserved.

: Superfine

: Lumax Cluster

1st runner up : Aar Aar Industries

: Pricol Cluster

2nd runner up :

: Subros Cluster

NRB Bearing

Training

Support

Consultancy

Copyright ©. All rights reserved.

MACE Kaizen Meet

MACE conducted Kaizen Meet for MSIL Vendors. Total of 200 Tier-1 & 400 Tier-2

vendors participated in this competition.

The results were as follow:

Tier-1

AWARD

VENDOR NAME

Winner

M/s KML Seat-1

Mr. Prateek Mandal

1st Runner Up

M/s Bright Autoplast

Mr. Himnashu Sharma

2nd Runner Up

M/s Tenneco

Mr. Sagar Vashisht

Tier-2

AWARD

VENDOR NAME

Winner

M/s Premier Pin

COUNSELLOR

CLUSTER

COUNSELLOR

Minda Cluster Mr. Amit

Chauhan

Mr. O.P.Uttareja

1st Runner Up M/s Bhamra Fabricators Subros

Cluster

Sona Cluster Mr. R.P.Bhatti

2nd Runner Up M/s Lakhani

Training

Support

Consultancy

Copyright ©. All rights reserved.

M/S Bhambra Fabricator receiving the Best Kaizen Award in T-2 Category

Training

Support

Consultancy

Copyright ©. All rights reserved.

Lumax T-2- Superfine receiving the winner Award of Quality Circle Competition

Training

Support

Consultancy

Copyright ©. All rights reserved.

M/S Precision Pin, Tier-2 of Minda receiving the Zero ppm Certificate

Training

Support

Consultancy

Copyright ©. All rights reserved.

10

National Workshop on “Enabling MSME

to be Competitive through Quality Tools”

M/S Subros receiving the Trophy for Best VSA Score in 2011-12

Training

Support

Copyright ©. All rights reserved.

Consultancy

Training

Support

Consultancy

Copyright ©. All rights reserved.

CII conducts annual Cluster summit in month of September in which various

clusters working with CII, ACMA & MACE are invited to participate by giving

their Kaizens & Case Studies on Problem Solving using 7 QC tools, Why-Why

analysis & Six Sigma.

In year 2011-12, 47 vendors of MSIL participated in this event where the best

Kaizen & the Case studies were adjudged by the Jury consisting of eminent

people from the industry.

A total of 285 Kaizens & 120 Case studies were received by CII for evaluation.

We are happy to inform that the following awards out of the total awards were

bagged by MSIL’s Tier-1 & 2 vendors:

Training

Support

Copyright ©. All rights reserved.

Consultancy

CII Cluster Championship Award Winners

Stream

MSME

Manufacturing

Excellence

Cost

Competitiveness

Energy Efficiency

Total Employee

Involvement

Vox Populi

Name of Company

Award

Auto Décor Pvt. Ltd.

1st

Horizon Industrial Products

Pvt. Ltd.

Shivai Enterprises Pvt. Ltd.

2nd

Bhambra Fabricators

1st

3rd

USV Ltd.

1st

Promed Export Pvt. Ltd.

2nd

Eastman Cast & Forge Ltd.

1st

Rakheja Engineers Pvt. Ltd.

2nd

Large

Award

Godrej & Boyce Mfg. Co. Ltd.

Mohali

Minda Industries Limited

1st

Sona Koyo Stering Systems

Ltd.

Godrej & Boyce Mfg. Co. Ltd.

Shirwal

Mahindra & Mahindra

Godrej & Boyce Mfg. Co. Ltd.

Shirwal

Mahindra & Mahindra

Tata Motors Ltd.

Godrej & Boyce Mfg. Co. Ltd.

Mohali

2nd

3rd

1st

1st

1st

2nd

3rd

1st

Godrej & Boyce. Mohali for Manufacturing Excellence

CII Kaizen Award Winners

Award

1st Award

2nd Award

3rd Award

Company

Suman Auto Parts Ltd.

Raunaq Automotive Components Ltd.

Krishna Maruti Limited

MSIL Vendors. The Case studies were based on completed MPS Projects.

11