Programme ACHEMA 2015

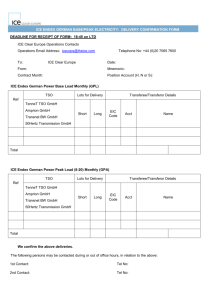

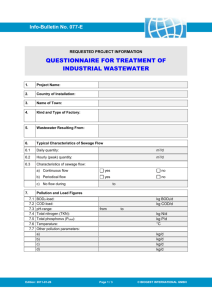

advertisement