A Review of IC Fabrication Technology - People

advertisement

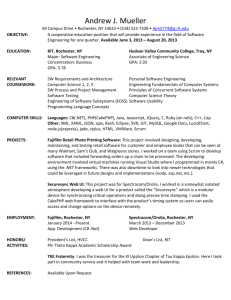

Review of IC Fabrication Technology

MICROELECTRONIC ENGINEERING

ROCHESTER INSTITUTE OF TECHNOLOGY

A Review of IC Fabrication Technology

Dr. Lynn Fuller

Webpage: http://people.rit.edu/lffeee

Microelectronic Engineering

Rochester Institute of Technology

82 Lomb Memorial Drive

Rochester, NY 14623-5604

Tel (585) 475-2035

Email: Lynn.Fuller@rit.edu

Department webpage: http://www.microe.rit.edu

Rochester Institute of Technology

Microelectronic Engineering

© March 3, 2009 Dr. Lynn Fuller, Professor

3-3-2009 Technology.ppt

Page 1

Review of IC Fabrication Technology

OUTLINE

§

§

§

§

§

§

§

§

Oxide Growth

Diffusion

Resistivity, Sheet Resistance, Resistance

Mobility

pn Junction

MOSFET Vt

Ion Implantation

Conclusion

Rochester Institute of Technology

Microelectronic Engineering

© March 3, 2009 Dr. Lynn Fuller, Professor

Page 2

Review of IC Fabrication Technology

OXIDE GROWTH

Oxide Thickness

Xox

Original Silicon

Surface

Silicon Consumed

0.46 Xox

PLAY

Rochester Institute of Technology

Microelectronic Engineering

© March 3, 2009 Dr. Lynn Fuller, Professor

Page 3

Review of IC Fabrication Technology

WET OXIDE GROWTH CHART

10

1

Xox ,(um)

10-1

C

0

0

3

1

0

120

0

110

0

0

0

1

900

10-2

1

10

Rochester Institute of Technology

Microelectronic Engineering

t, Time, (min)

100

PLAY

© March 3, 2009 Dr. Lynn Fuller, Professor

Page 4

Review of IC Fabrication Technology

DRY OXIDE GROWTH CHART

10

1

xox ,(um)

10-1

10-2

10

C

0

0

3

1

0

120

0

110

0

0

0

1

900

100

1,000

t, Time, (min)

Rochester Institute of Technology

Microelectronic Engineering

© March 3, 2009 Dr. Lynn Fuller, Professor

PLAY

Page 5

Review of IC Fabrication Technology

OXIDE GROWTH CALCULATOR

ROCHESTER INSTITUTE OF TECHNOLOGY

MICROELECTRONIC ENGINEERING

OXIDE.XLS

7/28/98

CALCULATION OF OXIDE THICKNESS

LYNN FULLER

ZIP

To use this spreadsheed change the values in the white boxes. The rest of the sheet is

protected and should not be changed unless you are sure of the consequences. The

calculated results are shown in the purple boxes.

CONSTANTS

K

1.38E-23 J/K

(Bo/Ao) dry

5760000 µm/hr

Ea (dry)

2 eV

(Bo/Ao) wet

71000000 µm/hr

Ea (wet)

1.96 eV

Bo dry

9.40E+02 µm2/hr

Ea (dry)

1.24 eV

Bo wet

250 µm2/hr

Ea (wet)

0.74 eV

VARIABLES

Temp=

time=

Xint=

1100 °C

48 min

wet

dry

<100>

<111>

500 Å

CHOICES

1=yes, 0=no

1

0

CALCULATIONS:

Xox (Oxide thickness)=(A/2){[1+(t+Tau)4B/A^2]^0.5 -1} =

B = Bo exp (-Ea/KTemp)

B/A = (Bo/Ao) exp (-Ea/KTemp)

A

Tau = (Xi2+AXi)/B

Xox

0.484600523

4.64E+00

0.104407971

0.01593147

µm2/hr

µm/hr

µm

hr

Oxide SiO2

Rochester Institute ofSilicon

Technology

Microelectronic Engineering

5788 Å

Origional Silicon

Surface Prior to

Oxide Growth

0.46 Xox (silicon consumed)

© March 3, 2009 Dr. Lynn Fuller, Professor

Page 6

Review of IC Fabrication Technology

OXIDE GROWTH EXAMPLES

1. Estimate the oxide thickness resulting from 50 min.

soak at 1100 °C in wet oxygen.

2. If 1000 Å of oxide exists to start with, what is

resulting oxide thickness after an additional 50 min.

soak at 1100 °C in dry oxygen.

Rochester Institute of Technology

Microelectronic Engineering

© March 3, 2009 Dr. Lynn Fuller, Professor

Page 7

Review of IC Fabrication Technology

DIFFUSION FROM A CONSTANT SOURCE

PLAY STOP

N(x,t) = No erfc (x/2

Dt )

N(x,t)

Solid

Solubility

Limit, No

p-type

n-type

Wafer Background Concentration, NBC

Xj

Rochester Institute of Technology

Microelectronic Engineering

© March 3, 2009 Dr. Lynn Fuller, Professor

Page 8

x

into wafer

Review of IC Fabrication Technology

Concentration/Surface Concentration = N/No

ERFC FUNCTION

10-0

10-1

10-2

10-3

10-4

10-5

10-6

10-7

10-8

10-9

10-10

10-11

0.0

Rochester Institute of Technology

Microelectronic Engineering

1.0

2.0

3.0

4.0

PLAY

© March 3, 2009 Dr. Lynn Fuller, Professor

Page 9

α=x/

4Dt

Review of IC Fabrication Technology

DIFFUSION CONSTANTS AND SOLID SOLUBILITY

DIFFUSION CONSTANTS

BORON

PHOSPHOROUS PHOSPHOROUS

TEMP

DRIVE-IN

PRE

900 °C

950

1000

1050

1100

1150

1200

1250

1.07E-15 cm2/s 2.09e-14 cm2/s

4.32E-15

6.11E-14

1.57E-14

1.65E-13

5.15E-14

4.11E-13

1.55E-13

9.61E-13

4.34E-13

2.12E-12

1.13E-12

4.42E-12

2.76E-12

8.78E-12

BORON

DRIVE-IN

SOLID

SOLUBILITY

NOB

7.49E-16 cm2/s 4.75E20 cm-3

3.29E-15

4.65E20

1.28E-14

4.825E20

4.52E-14

5.000E20

1.46E-13

5.175E20

4.31E-13

5.350E20

1.19E-12

5.525E20

3.65E-12

5.700E20

PLAY

Rochester Institute of Technology

Microelectronic Engineering

© March 3, 2009 Dr. Lynn Fuller, Professor

Page 10

PHOSPHOROUS

SOLID

SOLUBILITY

NOP

6.75E20 cm-3

7.97E20

9.200E20

1.043E21

1.165E21

1.288E21

1.410E21

1.533E21

Review of IC Fabrication Technology

TEMPERATURE DEPENDENCE OF DIFFUSION

CONSTANTS

PLAY

Temperature Dependence:

D = D0 Exp (-EA/kT) cm2/sec

Boron

D0 = 0.76

EA = 3.46

k = 8.625E-5

eV/°K

T in Kelvins

Phosphorous D0 = 3.85

EA = 3.66

Temperature Dependence of the Solid Solubility of

Boron and Phosphorous in Silicon

NOB = 3.5E17T + 1.325E20 cm-3

NOP = 2.45E18T - 1.53E21 cm-3

T in Celsius

T in Celsius

Rochester Institute of Technology

Microelectronic Engineering

© March 3, 2009 Dr. Lynn Fuller, Professor

Page 11

Review of IC Fabrication Technology

DIFFUSION FROM A LIMITED SOURCE

N(x,t) = Q’A(tp) Exp (- x2/4Dt)

π Dt

for erfc predeposit

Q’A (tp) = QA(tp)/Area = 2 No

PLAY

for ion implant predeposit

Q’A(tp) = Dose

PLAY

(Dptp) / π = Dose

Where D is the diffusion constant

at the drive in temperature and t is

the drive in diffusion time, Dp is

the diffusion constant at the

predeposit temperature and tp is the

predeposit time

Rochester Institute of Technology

Microelectronic Engineering

© March 3, 2009 Dr. Lynn Fuller, Professor

Page 12

Review of IC Fabrication Technology

DIFFUSION MASKING CALCULATOR

Select

Boron or Phosphorous

Enter

Temperature and Time

Rochester Institute of Technology

Microelectronic Engineering

© March 3, 2009 Dr. Lynn Fuller, Professor

Page 13

Review of IC Fabrication Technology

DIFFUSION MASKING

From: Hamilton and Howard

Rochester Institute of Technology

Microelectronic Engineering

© March 3, 2009 Dr. Lynn Fuller, Professor

Page 14

Review of IC Fabrication Technology

DIFFUSION AND DRIVE IN CALCULATIONS

Starting Wafer Resistivity

Starting Wafer Type

Rho =

n-type = 1

p-type = 1

Pre Deposition Temperature

Pre Deposition Time

Drive-in Temperature

Drive-in Time

CALCULATE

Solid Solubility at Temperature of Pre Deposition

Diffusion Constant at Temperature of Pre Deposition

Diffusion Constant at Temperature of Drive-in

10

1

0

950

15

1100

480

VALUE

4.65E+20

3.93E-15

1.43E-13

ohm-cm

1 or 0

1 or 0

°C

min

°C

min

UNITS

cm-3

cm/sec

cm/sec

CALCULATION OF DIFFUSION CONSTANTS

D0 (cm2/s)

Boron

Phosphorous

NOB = 3.5E17 (T) + 1.325E20

NOP = 2.45E18(T) - 1.53E21

0.76

3.85

EA (eV)

3.46

3.66

CALCULATIONS

Substrate Doping = 1 / (q µmax Rho)

Ratio of Nsub/Ns =

Approximate inverse erfc from erfc(u)~=e

VALUE

UNITS

4.42E+14 cm-3

9.51E-07

-u2

/(u(pi)^0.5)

RESULTS

xj after pre deposition =( (4Dp tp)^05)*(inv_erfc(Nsub/Ns))

Pre deposition Dose, QA= 2No (Dp tp/ π)^0.5

xj after drive-in = ((4 Dd td/QA) ln (Nsub (πDdtd)^0.5))^0.5

average doping Nave = Dose/xj

mobility (µ)

at Doping

equal to Nave

Rochester

Institute

of Technology

Sheet

Resistance

=

1/(q

(µ(Nave))Dose)

Microelectronic Engineering

Surface Concentration After Drive-in = Dose/ (pDt)^0.5

© March 3, 2009 Dr. Lynn Fuller, Professor

3.47

VALUE

0.13

9.87E+14

4.03

2.45E+18

109

58

8.68E+18

UNITS

µm

atoms/cm2

µm

atoms/cm3

cm2/V-s

ohms

cm-3

Page 15

Review of IC Fabrication Technology

DIFFUSION FROM A LIMITED SOURCE

GIVEN

Starting Wafer Resistivity

Starting Wafer Type

VALUE

Rho =

n-type = 1

p-type = 1

Pre Deposition Ion Implant Dose

UNITS

10 ohm-cm

1 1 or 0

0 1 or 0

4.00E+15 ions/cm2

Drive-in Temperature

Drive-in Time

1000 °C

360 min

CALCULATE

Diffusion Constant at Temperature of Drive-in

VALUE

UNITS

1.43E-14 cm/sec

CALCULATION OF DIFFUSION CONSTANTS

D0 (cm2/s) EA (eV)

0.76

3.46

3.85

3.66

Boron

Phosphorous

CALCULATIONS

Substrate Doping = 1 / (q µmax Rho)

VALUE

UNITS

4.42E+14 cm-3

RESULTS

Pre deposition Dose

xj after drive-in = ((4 Dd td/QA) ln (Nsub (π Ddtd)^0.5))^0.5

average doping Nave = Dose/xj

mobility (µ) at Doping equal to Nave

Sheet Resistance = 1/(q (µ(Nave))Dose)

Surface Concentration = Dose/ (pDt)^0.5

VALUE

UNITS

4.00E+15 atoms/cm2

1.25 µm

3.21E+19 atoms/cm3

57 cm2/V-s

27.6 ohms

1.28E+20 cm-3

Rochester Institute of Technology

Microelectronic Engineering

© March 3, 2009 Dr. Lynn Fuller, Professor

Page 16

Review of IC Fabrication Technology

DIFFUSION EXAMPLES

1. A predeposit from a p-type spin-on dopant into a 1E15 cm-3

wafer is done at 1000°C for 10 min. Calculate the resulting

junction depth and dose.

2. The spin-on dopant is removed and the Boron is driven in

for 4 hours at 1100 °C. What is the new junction depth?

Rochester Institute of Technology

Microelectronic Engineering

© March 3, 2009 Dr. Lynn Fuller, Professor

Page 17

Review of IC Fabrication Technology

RESISTANCE, RESISTIVITY, SHEET RESISTANCE

Resistance = R = ρ L/Area = ρs L/w

Resistivity = ρ = 1/( qµnn + qµpp)

ohms

ohm-cm

PLAY

Sheet Resistance = ρs = 1/ ( q µ(N) N(x) dx) ~ 1/( qµ Dose) ohms/square

PLAY

ρs = ρ / t

I

q = 1.6E-19 coul

L

slope = 1/R

Area

w

t

V

R

Rochester Institute of Technology

Microelectronic Engineering

© March 3, 2009 Dr. Lynn Fuller, Professor

Page 18

Review of IC Fabrication Technology

EXACT CALCULATION OF CARRIER CONCENTRATIONS

B

h

εo

εr

ni

Nc/T^3/2

Nv/T^3/2

1.11E+03

6.63E-34 Jsec

8.85E-14 F/cm

11.7

1.45E+10 cm-3

5.43E+15

2.02E+15

Nd =

Ed=

Na =

Ea=

Temp=

3.00E+16 cm-3

0.049 eV below Ec

8.00E+15 cm-3

0.045 eV above Ev

Donor Concentration

Acceptor Concentration

300 °K

Donor and Acceptor Levels (eV above or below Ev or Ec)

Boron

0.044

Phosphorous

0.045

Arsenic

0.049

CALCULATIONS: (this program makes a guess at the value of the fermi level and trys to minimize

the charge balance)

KT/q

0.026 Volts

Eg=Ego-(aT^2/(T+B))

1.115 eV

Nc

2.82E+19 cm-3

Nv

1.34E+01 cm-3

Fermi Level, Ef

0.9295 eV above Ev

free electrons, n = Nc exp(-q(Ec-Ef)KT)

2.17E+16 cm-3

Ionized donors, Nd+ = Nd*(1+2*exp(q(Ef-Ed)/KT))^(-1)

2.97E+16 cm-3

holes, p = Nv exp(-q(Ef-Ev)KT)

3.43E-15 cm-3

Ionized acceptors, Na- = Na*(1+2*exp(q(Ea-Ef)/KT))^(-1)

8.00E+15 cm-3

Charge Balance = p + Nd+ - n - Na3.22E+12 cm-3

Rochester Institute of Technology

Microelectronic Engineering

Click on Button to do Calculation

Button

Button

© March 3, 2009 Dr. Lynn Fuller, Professor

Page 19

Review of IC Fabrication Technology

RESISTIVITY OF SILICON VS DOPING

Impurity Concentration, N, cm-3

1021

ρ = 1/(qµ(N)N)

1020

1019

Because µ is a function of N

and N is the doping, the

relationship between resistivity

ρ and N is given in the figure

shown, or calculated from

equations for µ(N)

1018

Boron

1017

1016

Phosphorous

1015

1014

1013

10-4

10-3

10-2

10-1 100

Rochester Institute of Technology

Microelectronic Engineering

101

102

103

104

PLAY

Resistivity, ohm-cm

© March 3, 2009 Dr. Lynn Fuller, Professor

Page 20

Review of IC Fabrication Technology

1600

1400

1200

1000

800

600

400

200

0

PLAY

electrons

holes

10

^1

3

10

^1

4

10

^1

5

10

^1

6

10

^1

7

10

^1

8

10

^1

9

10

^2

0

Mobility (cm2/ V sec)

ELECTRON AND HOLE MOBILITY

Electron and hole mobilities

in silicon

at 300 K as

Arsenic

functions

Boron

of the total dopant

Phosphorus

concentration

(N). The

values plotted are the results

of the curve fitting

measurements from several

sources. The mobility curves

can be generated using the

equation below with the

parameters shown:

Total Impurity Concentration (cm-3)

(µmax-µmin)

PLAY

µ(N) = µ mi+

{1 + (N/Nref)α}

From Muller and Kamins, 3rd Ed., pg 33

Rochester Institute of Technology

Microelectronic Engineering

Parameter

µmin

µmax

Nref

α

© March 3, 2009 Dr. Lynn Fuller, Professor

Arsenic

52.2

1417

9.68X10^16

0.680

Page 21

Phosphorous

68.5

1414

9.20X10^16

0.711

Boron

44.9

470.5

2.23X10^17

0.719

Review of IC Fabrication Technology

TEMPERATURE EFFECTS ON MOBILITY

Derived empirically for silicon for T in K between 250 and 500 °K and for

N (total dopant concentration) up to 1 E20 cm-3

µn (T,N) = 88 Tn-0.57 +

1250 Tn-2.33

1 + [ N / (1.26E17 Tn 2.4 )] ^0.88 Tn -0.146

PLAY

µp (T,N) = 54.3

Tn-0.57

Rochester Institute of Technology

Microelectronic Engineering

407 Tn -2.33

+

1 + [ N / (2.35E17 Tn 2.4 )]^ 0.88 Tn -0.146

Where Tn = T/300

From Muller and Kamins, 3rd Ed., pg 33

© March 3, 2009 Dr. Lynn Fuller, Professor

Page 22

Review of IC Fabrication Technology

EXCELL WORKSHEET TO CALCULATE MOBILITY

MICROELECTRONIC ENGINEERING

3/13/2005

CALCULATION OF MOBILITY

Dr. Lynn Fuller

To use this spreadsheed change the values in the white boxes. The rest of the sheet is

protected and should not be changed unless you are sure of the consequences. The

calculated results are shown in the purple boxes.

CONSTANTS

Tn = T/300 = 1.22

VARIABLES

Temp=

N total

365 °K

1.00E+18 cm-3

n-type

p-type

<100>

CHOICES

1=yes, 0=no

1

0

Kamins, Muller and Chan; 3rd Ed., 2003, pg 33

mobility=

163 cm2/(V-sec)

Rochester Institute of Technology

Microelectronic Engineering

© March 3, 2009 Dr. Lynn Fuller, Professor

Page 23

Review of IC Fabrication Technology

EXCELL WORKSHEET TO CALCULATE RESISTANCE

Rochester Institute of Technology

Microelectronic Engineering

© March 3, 2009 Dr. Lynn Fuller, Professor

Page 24

Review of IC Fabrication Technology

ION IMPLANT EQUATIONS

Gaussian Implant Profile

N’

-(X-Rp)2

N(x) =

exp [

]

2π ∆Rp

2∆Rp2

Rp = Range

∆Rp = Straggle

N’ = Dose =

} From Curves

I

mqA dt

concentration cm-3

after implant

after anneal at

950 C, 15 min

Ni

Approximation

used in Vt

calculations

After Anneal

x

N’

-(X-Rp)2

N(x) = 2π ∆Rp2 + 2Dt exp [ 2(∆Rp2+Dt) ]

xi

where D is diffusion constant at the anneal temperature

t is time of anneal

Rochester Institute of Technology

Microelectronic Engineering

PLAY

© March 3, 2009 Dr. Lynn Fuller, Professor

Page 25

Approximation

N’ = Ni xi

Review of IC Fabrication Technology

ION IMPLANT RANGE

Projected Range, Rp ,(um)

1

As

10-1

B

P

Sb

10-2

10

100

Implantation Energy (KeV)

Rochester Institute of Technology

Microelectronic Engineering

© March 3, 2009 Dr. Lynn Fuller, Professor

1,000

PLAY

Page 26

Review of IC Fabrication Technology

Standard Deviation, ∆Rp ,(um)

ION IMPLANT STANDARD DEVIATION

0.1

B

0.01

P

As

Sb

0.001

10

Rochester Institute of Technology

Microelectronic Engineering

100

Implantation Energy (KeV)

© March 3, 2009 Dr. Lynn Fuller, Professor

1,000

PLAY

Page 27

Review of IC Fabrication Technology

ION IMPLANT MASKING CALCULATOR

Rochester Institute of Technology

Microelectronic Engineering

11/20/2004

IMPLANT MASK CALCULATOR

DOPANT SPECIES

B11

1

BF2

0

P31

0

Lance Barron

Dr. Lynn Fuller

Enter 1 - Yes

MASK TYPE

Resist

Poly

Oxide

Nitride

0 - No in white boxes

ENERGY

60

0

1

0

0

Thickness to Mask >1E15/cm3 Surface Concentration

KeV

4073.011 Angstroms

This calculator is based on Silvaco Suprem simulations using the Dual Pearson model.

In powerpoint click on spread sheet to change settings for a new calculation

Rochester Institute of Technology

Microelectronic Engineering

Lance Baron, Fall 2004

© March 3, 2009 Dr. Lynn Fuller, Professor

Page 28

Review of IC Fabrication Technology

REFERENCES

1. Basic Integrated Circuit Engineering, Douglas J. Hamilton, William

G. Howard, McGraw Hill Book Co., 1975.

2. Micro Electronics Processing and Device Design, Roy a. Colclaser,

John Wiley & Sons., 1980.

3. Device Electronics for Integrated Circuits, Richard S. Muller,

Theodore I. Kamins, Mansun Chan, John Wiley & Sons.,3rd Ed., 2003.

4. VLSI Technology, Edited by S.M. Sze, McGraw-Hill Book

Company, 1983.

5. Silicon Processing for the VLSI Era, Vol. 1., Stanley Wolf, Richard

Tauber, Lattice Press, 1986.

6. The Science and Engineering of Microelectronic Fabrication, Stephen

A. Campbell, Oxford University Press, 1996.

Rochester Institute of Technology

Microelectronic Engineering

© March 3, 2009 Dr. Lynn Fuller, Professor

Page 29

Review of IC Fabrication Technology

HOMEWORK - REVIEW OF IC TECHNOLOGY

1. If a window is etched in 5000 Å of oxide and the wafer is oxidized again for 50 min in wet

O2 at 1050 °C what is the new thickness (where it was 5000 Å), the thickness in the etch

window, and the step height in the silicon if all the oxide is etched off the wafer. Draw a

picture showing original Si surface.

2. A Boron diffusion is done into 5 ohm-cm n-type wafer involving two steps. First a short

predeposit at 950 C for 30 min., followed by removal of the diffusion source and a drive in at

1100 C for 2 hours. Calculate the junction depth and the sheet resistance of the diffused layers.

Estimate the oxide thickness needed to mask this diffusion.

3. For a pn junction with the p side doping of 1E17 and the n side at 1E15 calculate, width of

space charge layer, width on p side, on n side, capacitance per unit area, max electric field.

4. Calculate the threshold voltage for an aluminum gate PMOSFET fabricated on an n-type

wafer with doping of 5E15, a surface state density of 7E10, and gate oxide thickness of 150 Å.

What is the threshold voltage if the surface state density is 3E11?

5. Calculate the ion implant dose needed to shift the threshold voltage found in the problem

above to -1 Volts.

Rochester Institute of Technology

Microelectronic Engineering

PLAY

© March 3, 2009 Dr. Lynn Fuller, Professor

Page 30

Review of IC Fabrication Technology

HOMEWORK - EXACT CALCULATION OF SHEET

RESISTANCE FOR A DIFFUSED LAYER

1. A Boron p-type layer is diffused into an n-type silicon wafer

(1E15 cm-3) at 1100 °C for 1 hour. Calculate the exact value of the

sheet resistance and compare to the approximate value.

Sheet Resistance = ρs = 1/ ( q µ(N) N(x) dx) ~ 1/( qµ Dose) ohms/square

(µmax-µmin)

µ(N) = µ min +

α}

{1

+

(N/N

)

ref

for Boron

µmin

µmax

Nref

α

44.9

470.5

2.23X10^17

0.719

Let Q’ A(tp) = 5.633E15 cm-2

D= 1.55E-13 cm2/s

t = 1 hour

N(x,t) = Q’A(tp) Exp (- x2/4Dt)

Rochester Institute of Technology

Microelectronic Engineering

© March 3, 2009 Dr. Lynn Fuller, Professor

π Dt

Page 31

Review of IC Fabrication Technology

HW SOLUTION - EXACT CALCULATION OF SHEET

RESISTANCE FOR A DIFFUSED LAYER

Divide the diffused layer up into 100 slices and for each slice find

the doping and exact mobility. Calculate the sheet resistance from

the reciprocal of the sum of the conductance of each slice.

N(x)

NBC

x

xj

Rochester Institute of Technology

Microelectronic Engineering

© March 3, 2009 Dr. Lynn Fuller, Professor

Page 32