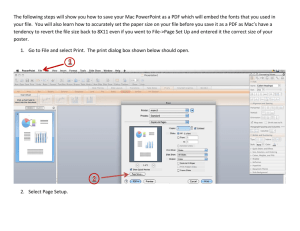

3. A tutorial: Using additional techniques to create and analyze a

advertisement