Works Visits

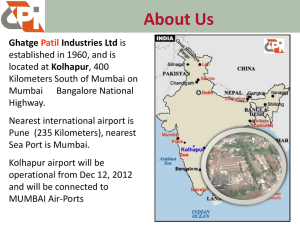

advertisement