SIMATIC PCS 7 Process Control System Product Brief

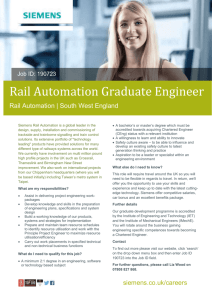

advertisement