Supporting Information

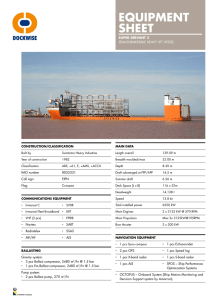

advertisement

Supporting Information Tailoring of porous structure in macro-meso-microporous SiC ultrathin fibers via electrospinning combined with polymer-derived ceramics route Bing Wanga, Yingde Wang*a, Yongpeng Lei*b,c, Nan Wua, Yanzi Goua, Cheng Hana, a Science and Technology on Advanced Ceramic Fibers and Composites Laboratory, National University of Defense Technology, Changsha 410073, P. R. China b College of Basic Education, National University of Defense Technology, Changsha 410073, P. R. China c State Key Laboratory of Materials-Oriented Chemical Engineering, Nanjing University of Technology, Nanjing 210009, P. R. China. *Corresponding author email: wyd502@163.com (Y. Wang); lypkd@163.com (Y. Lei) Fig.S1 Solution viscosity of the spinning solution as a function of the PCS concentration, implying the solution viscosity is proportional to the PCS concentration. Thus the solution viscosity can be expressed by a more intuitionistic parameter, PCS concentration. Fig.S2 Digital photos of the PCS ultrathin fibers synthesized with the PCS concentration of (a) 0.85 g ml-1 and (b) 0.95 g ml-1. Fig. S3. The TPD-MS profiles of cured PCS fibers: (a) survey profile at the temperature of 50~1600 °C and (b) closer view in the temperature range of 1000~1600 °C. The inset in (a) is the magnified image in the range of 500~900 °C; the inset in (b) is the magnified image for m/z: 2 H2, m/z: 16 CH4, m/z: 30 C2H6 and m/z: 44 CO2.