Designing VLSI Circuits and Systems with Nano Electro

advertisement

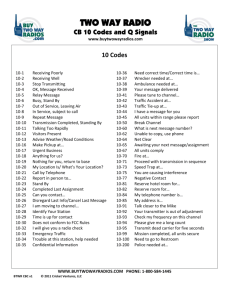

CMOS ET Workshop 2011 Designing VLSI Circuits and Systems with Nano Electro-Mechanical Relays Vladimir Stojanović (MIT) in collaboration with Tsu-Jae King Liu, Elad Alon (UC Berkeley) Dejan Marković (UCLA) June 16, 2011 Subthreshold Leakage: Game Over for CMOS 20 15 10 Etotal Edynamic 5 Eleakage 0.1 Normalized Energy/op Normalized Energy/op 25 0.2 0.3 0.4 VDD (V) 0.5 11 More parallelism does not help 10 1x 9 8x 2x 8 0 1 2 3 4 1/throughput 5 6 Leakage and sub-threshold slope define minimum energy/op for CMOS Parallelism cannot reduce power/throughput if already operating at minimum energy 2 NEM Relays to the Rescue Measured MEM Relay I-V Curve MEM Relay Energy vs. VDD Etotal=Edynamic NEM relays show zero leakage & sharp sub-threshold slope Could potentially enable reduced E/op with scaling Emin set by contact bond energy ~2aJ/switch (50x better than 90nm CMOS) R. Nathanael et al., “4-Terminal Relay Technology for Complementary 3 Logic,” IEDM 2009 3 NEM Relay Structure and Operation Tungsten Body Tungsten Channel Poly-SiGe Gate Poly-SiGe Anchor Poly-SiGe Beam /Flexure Tungsten Source/Drain OFF Relay: |Vgb| < Vpo (pull-out voltage) ON Relay: |Vgb| > Vpi (pull-in voltage) 4 Power-gating CMOS with NEM Relays B G 6 G 85μm 55μm 7 DVG = 2V VG (V) 8 S D VDD (V) 5 1.2 G 0.8 G 0.4 VEXT,R SyncCMOS (V) VH 0 3 A R OSC 2 1 0 -0.1 -0.05 0.05 0 0.1 R1 C1 R2 C2 0.15 VG Vb Time (s) 3% Duty Cycle 8 COSC External pulse gen Self-driven pulse generator VDD Power gate to CMOS logic Voltage (V) 6 H. Fariborzi et al. CICC 2010 4 Power-gating input (VOSC) 2 Gated CMOS VDD 0 0 0.5 1 1.5 2 Time (s) 2.5 3 3.5 5 Energy Gain Over CMOS Limited to Large Toff 8 10 VEXT,M 7 VEXT,R 10 sleep VG sleep VIO 6 10 CM T off (s) 5 CR VDD γCM 10 VEXT,M CMOS LOGIC Energy gain , p ,f ,CL 4 10 VDD CMOS LOGIC βCL , p ,f ,CL eCR βCL 1 3 10 (a) 2 10 2 5 10 (b) VIO=VNOM VIO=VEXT,M 1 10 32 45 65 90 130 180 Technology node (nm) 250 EM kRon, M I off Toff GG Energy gain ER VDD Ton Large Toff Switching overhead negligible 6 Area Savings More Significant 2 10 1 10 0 10 90nm CMOS Scaled Relay Peak Current density Ion [A/mm 2 ] -1 10 Current Relay -2 10 Ton overhead MOS 10s MOS 1ms MOS 10s MOS 1ms -3 10 1% 1% 10% 10% -4 10 Ton Ron,R Relay 10s 10k Relay 1ms 10k Relay 10s 1k Relay 1ms 1k -5 10 -6 10 -2 10 -1 0 1 10 10 10 MOS technology node and relay device pitch [ m] 2 10 Relays fabricated in metal backend - no area overhead Today: 1 mA/mm2 (ready for low-power apps) Scaled: 10-100 mA/mm2 (ready for high-power apps) 7 NEM Relay as a Logic Element Anchor Spring k Mechanical Model Damper b Mass m G Cgc S D Rs Cgb Rcs Simple model B Mechanical – spring, mass, damper Electrical – RC 4-terminal relay mimics MOSFET switch Rd Cdb Csb Rcd Electrostatic actuation is ambipolar Non-inverting logic is possible Actuation independent of source/drain voltages 8 Digital Circuit Design with NEM Relays NEMS: 12 switches CMOS: delay set by electrical time constant Quadratic delay penalty for stacking devices Buffer & distribute logical/electrical effort over many stages NEMS: delay dominated by mechanical movement Can stack ~100-200 devices before td,elec ≈ td,mech So, want all to switch simultaneously Implement logic as a single complex gate 9 Need to Compare at Block Level NEMS: 12 relays 4 gate delays 1 mechanical delay Delay Comparison vs. CMOS Single mechanical delay vs. several electrical gate delays For reasonable load, NEMS delay unaffected by fan-out/fan-in Area Comparison vs. CMOS Larger individual devices But often need fewer devices to implement same function F. Chen et al., “Integrated Circuit Design with NEM Relays,” ICCAD 2008 10 Example: 32-bit NEMS Adder Ripple carry configuration Cascade full adder cells to create larger complex gate Stack 32 NEMS, but still single mechanical delay 11 Scaled NEMS vs. CMOS Adders Energy/op vs. Delay/op across Vdd Compare vs Sklansky CMOS adder* 9x 10x 30x less capacitance Lower device Cg, Cd Fewer devices 2.4x lower Vdd 90nm technology No leakage energy For similar area: >9x lower E/op, >10x greater delay Patil et. al., “Robust Energy-Efficient Adder Topologies,” in Proc. 18th IEEE Symp. on Computer Arithmetic (ARITH'07). *D. 12 Parallelism: Trade Area for Performance Energy/op vs. Delay/op across Vdd & CL Can extend energy benefit up to GOP/s throughput As long as parallelism is available Area overhead bounded CMOS needs to be parallelized at some point too 13 Contact Resistance Energy/op vs. Delay/op across Vdd & CL Low contact R not critical Good news for reliability… Relays with W contacts lived through 65 B cycles 14 NEM Relay Circuit Technology Platform ISSCC 2010 – TD Award F. Chen et al, ISSCC2010 M. Spencer et al, JSSC Jan’11 15 NEMS VLSI design infrastructure P-cell Spectre Verilog-A Verilog-A Model Schematic Vout Device A A B Layout Verilog B Logic Synthesis Synthesis Place & Route Place Route LVS DRC Verilog-A model and Logic Synthesis created for NEMS technology The flow supports multiple device designs and foundries 16 Toward full systems - NEM Relay scaling 1um litho Relay size 120um x 150um 0.25um litho Scaled Relay size 20um x 20um Sematech 17 Conclusions NEMS unique features enable energy scaling beyond-CMOS Nearly ideal Ion/Ioff Switching delay largely independent of electrical Need to adapt circuit design style Reliability improving Circuit level insights critical (contact R) Demonstrated simple circuits Started building more complex and scaled systems Potentially order of magnitude lower E/op than CMOS Next steps: Large scale demonstration >10k relay uC block with scaled relays 18 Acknowledgements Circuit design Fred Chen, Hossein Fariborzi Matthew Spencer, Abhinav Gupta Cheng Wang, Kevin Dwan Device design Hei Kam, Rhesa Nathanael, Vincent Pott, Jaeseok Jeon Sponsors DARPA NEMS program FCRP (C2S2, MSD) MIT CICS Berkeley Wireless Research Center NSF 19 Contact Reliability Experiments Contact resistance [Ω] 1.E+06 100k specification 1.E+05 1.E+04 1.E+03 L=25m Measured in ambient 1.E+02 1.E+0 1.E+3 1.E+6 1.E+9 No. of on/off cycles Higher contact R, hard contact (W) improves reliability Limits power dissipation, material flow Current endurance record: 65 billion cycles Theory/experiments predict >1015 cycles @ 1V VDD H. Kam et al., “Design and Reliability of a Micro-Relay Technology…,” IEDM 2009 H. Kam et al., “A Predictive Contact Reliability Model for MEM Logic Switches,” IEDM 2010 20