introduction to beams

advertisement

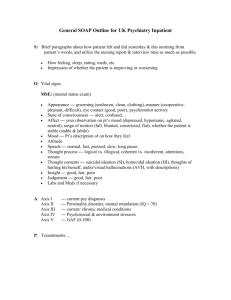

Unit 2: Engineering Science Unit code: L/601/1404 QCF Level: 4 Credit value: 15 OUTCOME 1 - TUTORIAL 1 STRESSES IN BEAMS DUE TO BENDING 1. Be able to determine the behavioural characteristics of elements of static engineering systems Simply supported beams: determination of shear force; bending moment and stress due to bending; radius of curvature in simply supported beams subjected to concentrated and uniformly distributed loads; eccentric loading of columns; stress distribution; middle third rule Beams and columns: elastic section modulus for beams; standard section tables for rolled steel beams; selection of standard sections e.g. slenderness ratio for compression member, standard section and allowable stress tables for rolled steel columns, selection of standard sections Torsion in circular shafts: theory of torsion and its assumptions e.g. determination of shear stress, shear strain, shear modulus; distribution of shear stress and angle of twist in solid and hollow circular section shafts You should judge your progress by completing the self assessment exercises. It is assumed that students doing this tutorial are already familiar with the following work at national level: The reaction forces in simply supported beams. Moments of force. First and second moments of area. Basic stress and strain (direct and shear) If you need to study this, you will find the material elsewhere on the web site. CONTENTS 1. INTRODUCTION 2. THE BENDING FORMULA 2.1 Neutral Axis 2.2 Radius of Curvature 2.3 Relationship between Strain and Radius of Curvature 2.4 Relationship between Stress and Bending Moment 2.5 Standard Sections © D.J.DUNN 1 1 INTRODUCTION A beam is a structure that is loaded laterally (sideways) to its length. These loads produce bending and bending is the most severe way of stressing a component. Suppose you were given a simple rod or a ruler and asked to break it. You would struggle to break it by stretching it or twisting it but it would be easy to break by bending it. A beam may have point loads or a uniformly distributed load (udl) such as might occur due to its weight or the weight of a wall built along it. We normally show the loads with simplified diagrams like this. There are other ways of supporting beams as shown below but you don’t need to study these. The loads produce shear force and bending moments that vary with position along the length. You should already know how to construct shear force and bending moment diagrams for simply supported beams. When a bending moment M is applied to a beam, one surface is compressed (negative stress) and the other is stretched (tensile positive stress). The stress varies across the section from a maximum negative to a maximum positive as shown. Somewhere in between there is a longitudinal layer that is not stressed (neutral) and this layer lays on the NEUTRAL AXIS. The neutral axis is through the centroid for pure bending and the centroid is at the middle of symmetrical sections. In addition the transverse forces produce shearing on a given section as indicated. The purpose of this tutorial is to enable you to calculate the stress due to the bending moment. We will derive the following three part equation known as the bending equation. M E I y R M is the bending moment at a given point along the length. I is the second moment of area of the sectional area about the neutral axis. σ is the stress due to bending at a distance y from the neutral axis. E is the modulus of elasticity. R is the radius of curvature. © D.J.DUNN 2 WORKED EXAMPLE No. 1 The free body diagram shown is for a simply supported beam with point loads. Calculate the reaction forces Ra and Rb. MOMENTS ΣM = 0 about any point so it is convenient here to use the left end at the point where R a acts. Since the reaction at that point cannot produce a moment, it is eliminated from the balance. (Remember clockwise is negative) (Rb x 5) - (60 x 4) - (20 x 2) = 0 (Rb x 5) = (60 x 4) + (20 x 2) Rb = 280/5 = 56 kN VERTICAL FORCES ΣFy = 0 (remember up is positive) Ra + Rb - 20 - 60 = 0 Ra + Rb = 80 kN Ra + 56 = 80 kN Ra = 80 - 56 = 24 kN UNIFORMLY DISTRIBUTED LOADS (u.d.l.) A uniform load is one which is evenly distributed along a length such as the weight of the beam or a wall built on top of a beam. It is depicted by a series of arrows as shown. We usually denote the loading as w Newtons per metre. We deal with uniform loads by replacing them with an equivalent point load. If the load extends over a length x metres then the total load is F = wx Newton. We replace the u.d.l. with a single point load at the middle a distance of x/2 metres from the end. WORKED EXAMPLE No. 2 A uniform load on a beam is shown below. It has a value of 2.5 kN per metre. Calculate the reaction forces. SOLUTION If the load is 2.5 kN for each metre of length then the total load is 4 x 2.5 = 10 kN This load is equivalent to a single point load at the middle of 10 kN. It should be apparent that in this case, the reactions must be equal to half the total load so are both 5 kN acting up. Let’s do the calculation anyway. Taking moments about Rb we have (10 x 2) - (Ra x 4 ) = 0 4Ra = 20 Ra = 5 kN Balancing vertical forces Ra + Rb - 10 = 0 5 + Rb - 10 = 0 Rb = 5 kN © D.J.DUNN 3 WORKED EXAMPLE No. 3 A beam 4 m long rests on simple supports and carries a uniform load of 2.5 kN/m over the first 1.5 m as shown. Calculate the reaction forces. The total load is now 1.5 x 2.5 = 3.75 kN This acts at the middle of the length 0.75 m from the end. Balancing moments about Ra we have (Rb x 4) - (3.75 x 0.75) = 0 Rb = 2.8125/4 = 0.703 kN Balancing vertical forces © D.J.DUNN Rb + Ra = 3.75 4 Ra = 3.75 - 0.703 = 3.05 Kn 2. 2.1 THE BENDING FORMULA NEUTRAL AXIS This is the axis along the length of the beam which remains unstressed, neither compressed nor stretched when it is bent. Normally the neutral axis passes through the centroid of the cross sectional area. For simple rectangular and circular sections, this is the axis along the centre line. Consider that the beam is bent into an arc of a circle through angle radians. AB is on the neutral axis and is the same length before and after bending. The radius of the neutral axis is R. Remember the length of an arc is radius x angle in radians 2.2 RADIUS OF CURVATURE Normally the beam does not bend into a circular arc. However, what ever shape the beam takes under the sideways loads; it will basically form a curve on an x – y graph. In maths, the radius of curvature at any point on a graph is the radius of a circle that just touches the graph and has the same tangent at that point. 2.3 RELATIONSHIP BETWEEN STRAIN AND RADIUS OF CURVATURE The length of AB AB = R Consider a layer of material distance y from the neutral axis as shown. This layer is stretched because it must become longer and the material has stress and strain in it in a lengthwise direction as a result. (If y was to the inside of the neutral axis it would be compressed and become shorter). The radius of the layer is R + y. The length of this layer is the line DC. DC = (R + y) = change in length/original length This layer is strained and strain () is defined as Substitute AB = R and DC = (R + y) R y R DC AB y AB R R The modulus of Elasticity (E) relates direct stress () and direct strain () for an elastic material and the definition is as follows. stress E strain y R E Substitute and E R y R y It follows that stress and strain vary along the length of the beam depending on the radius of curvature. We will now go on to show that the radius of curvature depends upon the bending moment M acting at any given point along the length of the beam. © D.J.DUNN 5 2.4 RELATIONSHIP BETWEEN STRESS AND BENDING MOMENT Consider a beam with a consistent shape along its length. An arbitrary oval shape is shown here. Think of the beam as being made of many thin layers of material running the length of the beam and held together by molecular forces. Consider one such elementary layer at a given point along the length at a distance y from the neutral axis. When the cross section is viewed end on it appears as an elementary strip width b and thickness y. The cross sectional area is A. The elementary strip is a small part of the total cross sectional Area and is denoted in calculus form as A. The strip may be regarded as a thin rectangle width b and height y so A = b y The stress on the strip is = Ey/R If the layer shown is stretched, then there is a small force F pulling normal to the section trying to slide the layer out of the material in a lengthwise direction. This force must be the product of the stress and the area and is a small part of the total force acting on the section F. Ey Ey δF δA Substitute and δF δA R R Consider that the whole beam s made up of many such layers. Some are being stretched and pull normal to the section and some are compressed and push. The total force acting on the section is the sum of all these small forces. Ey F δF δA R In the limit as y tends to zero, the number of strips to be summed tends to infinity. The small quantities y and A become the differential coefficient dy and dA. The total force is given by the integration top Ey E F dA R R bottom top y dA bottom top The expression y dA is by definition the first moment of area of the shape about the centroid. bottom Evaluating this expression would give zero since any first moment of area is zero about the centroid. The centroid in this case is on the neutral axis. The areas above and below the neutral axis are equal. Half the force is a compressive force pushing into the diagram, and half is tensile pulling out. They are equal and opposite so it follows that F = 0 which is sensible since cross sections along the length of a beam obviously are held I equilibrium. © D.J.DUNN 6 The diagram indicates that the two forces produce a turning moment about the neutral axis because half the section is in tension and half in compression. This moment must be produced by the external forces acting on the beam making it bend in the first place. This moment is called the bending moment M. Consider the moment produced by the force on the elementary strip F. It acts a distance y from the neutral axis so the moment produced is M = y F In the limit as y tends to zero the total moment is found by reverting to calculus again. M yδδ top ydF bottom M E R top bottom y Ey dA R top y 2 dA bottom top The expression y 2 dA is by definition the second moment of area about the neutral axis and this is not bottom top zero but has a definite value. In general it is denoted by the symbol I. I y 2 dA bottom We may now write the moment as M Combining E M E I and rearrange it to I R R E M E M E and we now have I R R y I y R This is called the bending equation and it has 3 parts. My Ey or This indicates I R that the stress in a beam depends on the bending moment and so the maximum stress will occur where the bending moment is a maximum along the length of the beam. It also indicates that stress is related to distance y from the neutral axis so it varies from zero to a maximum at the top or bottom of the section. One edge of the beam will be in maximum tension and the other in maximum compression. In beam problems, we must be able to deduce the position of greatest bending moment along the length. If the stress is required at a given point along the beam we use either © D.J.DUNN 7 2.5 STANDARD SECTIONS At this stage, don't have to worry about how M is found, it is covered later. For simple sections the value of I may be determined by mathematics. The good news is that for standard engineering sections, they may be looked up in tables. Steel and other products used in structural engineering are manufactured with standard cross sections and sizes and in the UK they are made to British Standard BS4. In this you will find Universal Beams, Universal Columns and much more with the sizes and sectional properties listed. You will find ‘I’ sections, ‘T’ sections, ‘U’ sections and more. You will find names like RSJ (Rolled Steel Joists) and RSC (Rolled Steel Columns) which refer to the method of manufacture. A sample of the table is attached for ‘I’ section beams. The areas and second moments of area are listed in the standards and since the distance y to the edge is also I known they list a property called the ELASTIC MODULUS and this is defined as z . The stress at the y edge of the beam is then found from the equation: My M . I Z For standard shapes the second moment of area can be calculated with the formulae shown. This is covered in the pre-requisite tutorial on moments of area. The following formulae apply to standard shapes. For more complex shapes such as TEE and U sections, you will need to study the pre-requisite level tutorial in order to solve the second moment of area. There are also many computer programmes for solving beam problems that contain the standard information or calculate the second moment of area when the dimensions are supplied. The Archon Engineering web site has many such programmes. You will currently (2005) find details of steel sections at www.roymech.co.uk © D.J.DUNN 8 WORKED EXAMPLE No.4 A beam has a rectangular cross section 80 mm wide and 120 mm deep. It is subjected to a bending moment of 15 kNm at a certain point along its length. It is made from metal with a modulus of elasticity of 180 GPa. Calculate the maximum stress on the section. SOLUTION B = 80 mm, D = 100 mm. It follows that the value of y that gives the maximum stress is 50 mm. Remember all quantities must be changed to metres in the final calculation. BD3 80 x 1003 I 6.667 x 10 6 mm 4 6.667 x 10 6 m 4 12 12 M I y My 15 x 103 x 0.05 112.5 x 10 6 N/m 2 6 I 6.667 x 10 WORKED EXAMPLE No.5 A beam has a hollow circular cross section 40 mm outer diameter and 30 mm inner diameter. It is made from metal with a modulus of elasticity of 205 GPa. The maximum tensile stress in the beam must not exceed 350 MPa. Calculate the following. (i) the maximum allowable bending moment. (ii) the radius of curvature. SOLUTION D = 40 mm, d = 30 mm I = (404 - 304)/64 = 85.9 x 103 mm4 or 85.9 x 10-9 m4. The maximum value of y is D/2 so y = 20 mm or 0.02 m M σ I y σI 350 x 10 6 x 85.9 x 10 -9 1503 Nm or 1.503 M Nm y 0.02 σ E y R M R Ey 205 x 10 9 x 0.02 11.71 m σ 350 x 10 6 © D.J.DUNN 9 WORKED EXAMPLE No.6 A beam is made from a universal column with an ‘I’ section to BS4. The size of the beam is 356 x 127 x 39. The modulus of elasticity of 205 GPa. The maximum tensile stress in the beam must not exceed 350 MPa. Calculate the following. (i) The maximum allowable bending moment. (ii) The radius of curvature. SOLUTION It is normal to arrange the ‘I’ section so that it bends about the x-x axis. From the table (at the end of the tutorial) the elastic modulus z is 576 cm3 (576 x 10-9 m3) The depth of the section is 353.4 mm so y = 176.7 mm M σ z M σ z 350 x 10 6 x 576 x 10 -9 201 Nm σ E y R R Ey 205 x 10 9 x 0.1767 103.4 m σ 350 x 10 6 SELF ASSESSMENT EXERCISE No.1 1. A beam has a bending moment (M) of 3 kNm applied to a section with a second moment of area (I) of 5 x 10-3 m4. The modulus of elasticity for the material (E) is 200 x 109 N/m2. Calculate the radius of curvature. (Answer 333.3 km). 2. The beam is Q1 has a distance from the neutral axis to the edge in tension of 60 mm. Calculate the stress on the edge. (Answer 36 kPa). 3. A beam under test has a measured radius of curvature of 300 m. The bending moment applied to it is 8 Nm. The second moment of area is 8000 mm 4. Calculate the modulus of elasticity for the material. (Answer 300 GPa). 4. An ‘I’ section universal beam made to BS4 had dimensions 610 x 305 x 238. Assuming the modulus of elasticity is 200 GPa, calculate the stress and radius of curvature when a bending moment of 500 kNm is applied about the x axis. (Answer 75.9 MPa and 838 m) 5. A beam must withstand a bending moment of 360 Nm. If the maximum stress must not exceed 250 MPa, determine the elastic modulus ‘z’ and select an appropriate ‘I’ section from the table for BS3 Universal Beams. (Answer z = 1440 cm3 so select 457 x 152 x 82) © D.J.DUNN 10 UNIVERSAL BEAMS ‘I’ SECTION Thickness of Designation Mass per m Depth of Section Width of Section Web Flange Root Radius Depth between Fillets Area of Section Second Moment Area Axis x-x Axis y-y Radius of Gyration Axis Axis x-x y-y Elastic Modulus Axis x-x Axis y-y Plastic Modulus Axis x-x Axis y-y M h b s t r d A Ix Iy rx ry Zx Zy Sx Sy kg/m mm mm mm mm mm mm cm2 cm4 cm4 cm cm Cm3 cm3 cm3 cm3 914x419x388 388 921 420.5 21.4 36.6 24.1 799.6 494 719635 45438 38.2 9.59 15627 2161 17665 3341 914x419x343 343.3 911.8 418.5 19.4 32 24.1 799.6 437 625780 39156 37.8 9.46 13726 1871 15477 2890 914x305x289 289.1 926.6 307.7 19.5 32 19.1 824.4 368 504187 15597 37 6.51 10883 1014 12570 1601 914x305x253 253.4 918.4 305.5 17.3 27.9 19.1 824.4 323 436305 13301 36.8 6.42 9501 871 10942 1371 914x305x224 224.2 910.4 304.1 15.9 23.9 19.1 824.4 286 376414 11236 36.3 6.27 8269 739 9535 1163 914x305x201 200.9 903 303.3 15.1 20.2 19.1 824.4 256 325254 9423 35.7 6.07 7204 621 8351 982 838x292x226 226.5 850.9 293.8 16.1 26.8 17.8 761.7 289 339704 11360 34.3 6.27 7985 773 9155 1212 838x292x194 193.8 840.7 292.4 14.7 21.7 17.8 761.7 247 279175 9066 33.6 6.06 6641 620 7640 974 838x292x176 175.9 834.9 291.7 14 18.8 17.8 761.7 224 246021 7799 33.1 5.9 5893 535 6808 842 762x267x197 196.8 769.8 268 15.6 25.4 16.5 686 251 239957 8175 30.9 5.71 6234 610 7167 959 762x267x173 173 762.2 266.7 14.3 21.6 16.5 686 220 205282 6850 30.5 5.58 5387 514 6198 807 762x267x147 146.9 754 265.2 12.8 17.5 16.5 686 187 168502 5455 30 5.4 4470 411 5156 647 762x267x134 133.9 750 264.4 12 15.5 16.5 686 171 150692 4788 29.7 5.3 4018 362 4644 570 686x254x170 170.2 692.9 255.8 14.5 23.7 15.2 615.1 217 170326 6630 28 5.53 4916 518 5631 811 686x254x152 152.4 687.5 254.5 13.2 21 15.2 615.1 194 150355 5784 27.8 5.46 4374 455 5000 710 686x254x140 140.1 683.5 253.7 12.4 19 15.2 615.1 178 136267 5183 27.6 5.39 3987 409 4558 638 686x254x125 125.2 677.9 253 11.7 16.2 15.2 615.1 159 117992 4383 27.2 5.24 3481 346 3994 542 610x305x238 238.1 635.8 311.4 18.4 31.4 16.5 540 303 209471 15837 26.3 7.23 6589 1017 7486 1574 Designation Mass per m Depth of Section Width of Section Thickness of Web Root Radius Depth between Fillets Area of Section Flange Second Moment Area Axis x-x Axis y-y Radius of Gyration Axis Axis x-x y-y Elastic Modulus Axis x-x Axis y-y Plastic Modulus Axis x-x Axis y-y M h b s t r d A Ix Iy rx ry Zx Zy Sx Sy kg/m mm mm mm mm mm mm cm2 cm4 cm4 cm cm cm3 cm3 cm3 cm3 610x305x179 179 620.2 307.1 14.1 23.6 16.5 540 228 153024 11408 25.9 7.07 4935 743 5547 1144 610x305x149 149.2 612.4 304.8 11.8 19.7 16.5 540 190 125876 9308 25.7 7 4111 611 4594 937 610x229x140 139.9 617.2 230.2 13.1 22.1 12.7 547.6 178 111777 4505 25 5.03 3622 391 4142 611 610x229x125 125.1 612.2 229 11.9 19.6 12.7 547.6 159 98610 3932 24.9 4.97 3221 343 3676 535 610x229x113 113 607.6 228.2 11.1 17.3 12.7 547.6 144 87318 3434 24.6 4.88 2874 301 3281 469 610x229x101 101.2 602.6 227.6 10.5 14.8 12.7 547.6 129 75780 2915 24.2 4.75 2515 256 2881 400 533x210x122 122 544.5 211.9 12.7 21.3 12.7 476.5 155 76043 3388 22.1 4.67 2793 320 3196 500 533x210x109 109 539.5 210.8 11.6 18.8 12.7 476.5 139 66822 2943 21.9 4.6 2477 279 2828 436 533x210x101 101 536.7 210 10.8 17.4 12.7 476.5 129 61519 2692 21.9 4.57 2292 256 2612 399 533x210x92 92.1 533.1 209.3 10.1 15.6 12.7 476.5 117 55227 2389 21.7 4.51 2072 228 2360 356 533x210x82 82.2 528.3 208.8 9.6 13.2 12.7 476.5 105 47539 2007 21.3 4.38 1800 192 2059 300 457x191x98 98.3 467.2 192.8 11.4 19.6 10.2 407.6 125 45727 2347 19.1 4.33 1957 243 2232 379 © D.J.DUNN 11 457x191x89 89.3 463.4 191.9 10.5 17.7 10.2 407.6 114 41015 2089 19 4.29 1770 218 2014 338 457x191x82 82 460 191.3 9.9 16 10.2 407.6 104 37051 1871 18.8 4.23 1611 196 1831 304 457x191x74 74.3 457 190.4 9 14.5 10.2 407.6 94.6 33319 1671 18.8 4.2 1458 176 1653 272 457x191x67 67.1 453.4 189.9 8.5 12.7 10.2 407.6 85.5 29380 1452 18.5 4.12 1296 153 1471 237 457x152x82 82.1 465.8 155.3 10.5 18.9 10.2 407.6 105 36589 1185 18.7 3.37 1571 153 1811 240 457x152x74 74.2 462 154.4 9.6 17 10.2 407.6 94.5 32674 1047 18.6 3.33 1414 136 1627 213 457x152x67 67.2 458 153.8 9 15 10.2 407.6 85.6 28927 913 18.4 3.27 1263 119 1453 187 457x152x60 59.8 454.6 152.9 8.1 13.3 10.2 407.6 76.2 25500 795 18.3 3.23 1122 104 1287 163 457x152x52 52.3 449.8 152.4 7.6 10.9 10.2 407.6 66.6 21369 645 17.9 3.11 950 84.6 1096 133 406x178x74 74.2 412.8 179.5 9.5 16 10.2 360.4 94.5 27310 1545 17 4.04 1323 172 1501 267 406x178x67 67.1 409.4 178.8 8.8 14.3 10.2 360.4 85.5 24331 1365 16.9 3.99 1189 153 1346 237 406x178x60 60.1 406.4 177.9 7.9 12.8 10.2 360.4 76.5 21596 1203 16.8 3.97 1063 135 1199 209 406x178x54 54.1 402.6 177.7 7.7 10.9 10.2 360.4 69 18722 1021 16.5 3.85 930 115 1055 178 406x140x46 46 403.2 142.2 6.8 11.2 10.2 360.4 58.6 15685 538 16.4 3.03 778 75.7 888 118 406x140x39 39 398 141.8 6.4 8.6 10.2 360.4 49.7 12508 410 15.9 2.87 629 57.8 724 90.8 356x171x67 67.1 363.4 173.2 9.1 15.7 10.2 311.6 85.5 19463 1362 15.1 3.99 1071 157 1211 243 356x171x57 57 358 172.2 8.1 13 10.2 311.6 72.6 16038 1108 14.9 3.91 896 129 1010 199 356x171x51 51 355 171.5 7.4 11.5 10.2 311.6 64.9 14136 968 14.8 3.86 796 113 896 174 356x171x45 45 351.4 171.1 7 9.7 10.2 311.6 57.3 12066 811 14.5 3.76 687 94.8 775 147 356x127x39 39.1 353.4 126 6.6 10.7 10.2 311.6 49.8 10172 358 14.3 2.68 576 56.8 659 89.1 356x127x33 33.1 349 125.4 6 8.5 10.2 311.6 42.1 8249 280 14 2.58 473 44.7 543 70.3 Thickness of Designation Mass per m Depth of Section Width of Section Web Flange Root Radius Depth between Fillets Area of Section Second Moment Area Axis x-x Axis y-y Radius of Gyration Axis Axis x-x y-y Elastic Modulus Axis x-x Axis y-y Plastic Modulus Axis x-x Axis y-y M h b s t r d A Ix Iy rx ry Zx Zy Sx Sy kg/m mm mm mm mm mm mm cm2 cm4 cm4 cm cm cm3 cm3 cm3 cm3 305x165x54 54 310.4 166.9 7.9 13.7 8.9 265.2 68.8 11696 1063 13 3.93 754 127 846 196 305x165x46 46.1 306.6 165.7 6.7 11.8 8.9 265.2 58.7 9899 896 13 3.9 646 108 720 166 305x165x40 40.3 303.4 165 6 10.2 8.9 265.2 51.3 8503 764 12.9 3.86 560 92.6 623 142 305x127x48 48.1 311 125.3 9 14 8.9 265.2 61.2 9575 461 12.5 2.74 616 73.6 711 116 305x127x42 41.9 307.2 124.3 8 12.1 8.9 265.2 53.4 8196 389 12.4 2.7 534 62.6 614 98.4 305x127x37 37 304.4 123.4 7.1 10.7 8.9 265.2 47.2 7171 336 12.3 2.67 471 54.5 539 85.4 305x102x33 32.8 312.7 102.4 6.6 10.8 7.6 275.9 41.8 6501 194 12.5 2.15 416 37.9 481 60 305x102x28 28.2 308.7 101.8 6 8.8 7.6 275.9 35.9 5366 155 12.2 2.08 348 30.5 403 48.5 305x102x25 24.8 305.1 101.6 5.8 7 7.6 275.9 31.6 4455 123 11.9 1.97 292 24.2 342 38.8 254x146x43 43 259.6 147.3 7.2 12.7 7.6 219 54.8 6544 677 10.9 3.52 504 92 566 141 254x146x37 37 256 146.4 6.3 10.9 7.6 219 47.2 5537 571 10.8 3.48 433 78 483 119 254x146x31 31.1 251.4 146.1 6 8.6 7.6 219 39.7 4413 448 10.5 3.36 351 61.3 393 94.1 254x102x28 28.3 260.4 102.2 6.3 10 7.6 225.2 36.1 4005 179 10.5 2.22 308 34.9 353 54.8 254x102x25 25.2 257.2 101.9 6 8.4 7.6 225.2 32 3415 149 10.3 2.15 266 29.2 306 46 254x102x22 22 254 101.6 5.7 6.8 7.6 225.2 28 2841 119 10.1 2.06 224 23.5 259 37.3 203x133x30 30 206.8 133.9 6.4 9.6 7.6 172.4 38.2 2896 385 8.71 3.17 280 57.5 314 88.2 203x133x25 25.1 203.2 133.2 5.7 7.8 7.6 172.4 32 2340 308 8.56 3.1 230 46.2 258 70.9 203x102x23 23.1 203.2 101.8 5.4 9.3 7.6 169.4 29.4 2105 164 8.46 2.36 207 32.2 234 49.8 178x102x19 19 177.8 101.2 4.8 7.9 7.6 146.8 24.3 1356 137 7.48 2.37 153 27 171 41.6 152x89x16 16 152.4 88.7 4.5 7.7 7.6 121.8 20.3 834 89.8 6.41 2.1 109 20.2 123 31.2 127x76x13 13 127 76 4 7.6 7.6 96.6 16.5 473 55.7 5.35 1.84 74.6 14.7 84.2 22.6 © D.J.DUNN 12