C lamping system

advertisement

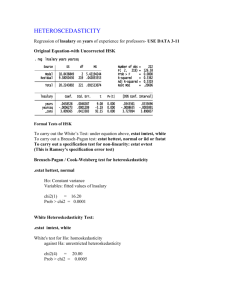

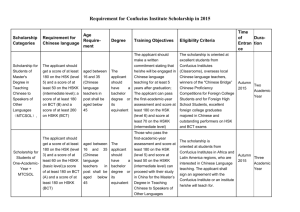

C lamping system HSK clamping systems......................................316-325 SK clamping systems........................................ 326-331 Precision- collet chucks......................................332-334 Saw blade holders.................................................... 335 Sleeves............................................................. 336-341 HSKchuck 82000 S awblades HSK 63F Drill chuck HSK in acc. with DIN 69893, clamping range 1-13 and 3-16 mm For drills and light cutting tools, suitable for right-hand and left-hand rotation Machine:CNC router A Design: Inifinitely adjustable n (max) = 20.000 rpm d1 D 82000 Shank mm A mm D mm d1 mm DT Order No. HSK 63 F 90 50 1-13 ◊ 40015551 HSK 63 F 97 57 3-16 ◊ 40003140 S hank type cutters C utter with bore H oggers Application: A ccessories DP - Tools C lamping system K nives D rills Screw driver SW 6 included in the scope of delivery 316 HSKchuck 82000 A 82000 Shank mm A mm D/thread mm d1 mm for collet chucks no. DT Order No. HSK 63 F 80 60/M48 6-25,4 462 E (bis 25 mm) ◊ 10032786 HSK 63 F 115 60/M48 6-25,4 462 E (bis 25 mm) ◊ 10035785 HSK 63 F 100 M19x1 (Mini) 1-12 426 E (bis12mm) ◊ 10164024 HSK 63 F 160 M19x1 (Mini) 1-12 426 E (bis12mm) ◊ 10164025 Delivery without hook wrench and collet. Please observe the minimum clamping length on the tool shaft. For hook wrenches see chapter “Accessories” For collet chucks see pages 332-333. C utter with bore d1 D hank type cutters Design: With a channel for data chips. Clamping nut ball bearing mounted, collets can therefore be mounted and removed easily. n (max) = 24.000 rpm S A Machine:CNC router H oggers For drills and light cutting tools Suitable for right-hand and left-hand rotation D rills Application: S awblades HSK 63F Collet chuck HSK in acc. with DIN 69893, for collets up to 25mm 317 A ccessories DP - Tools C lamping system K nives d1 D HSKchuck 81000 S awblades HSK 63 F Arbor HSK in acc. with DIN 69893 For holding boring tools. The admissible speed of the bor- ing tools is to be observed. Design:Channel for data chips. Very high clamping force and opti- mal safety due to M16 draw bolt with rigid cover disc. Anti-turn locking device by means of feather keys. L2 A Machine:CNC router d1 81000 Shank mm d1 mm L2 mm A mm DKN mm weight kg DT Order No. HSK 63 F 30 40 75 8x2 1,55 ◊ 10013522 HSK 63 F 30 50 75 8x2 1,60 ◊ 10013526 HSK 63 F 30 60 75 8x2 1,65 ◊ 10013527 HSK 63 F 30 80 75 8x2 1,75 ◊ 10013529 HSK 63 F 30 100 75 8x2 1,90 ◊ 10014498 Draw bolt and cover disc are in the scope of delivery. A ccessories DP - Tools C lamping system K nives D rills S hank type cutters C utter with bore H oggers Application: 318 HSKchuck 82000 d1 mm A mm DT Order No. HSK 63 F 6 80 10013534 HSK 63 F 8 80 ○ ○ HSK 63 F 10 80 ◊ 10013532 10013533 HSK 63 F 12 80 ◊ 10014499 HSK 63 F 14 80 ◊ 10014501 HSK 63 F 16 80 ◊ 10013531 HSK 63 F 20 80 ◊ 10013530 Clamping surface according to DIN 1835 form B e1 mm 0 -1 h1 mm h6 b1 mm +0,05 0 h13 i1 mm +2 0 6 4,2 18 4,8 36 8 5,5 18 6,6 36 10 7 20 8,4 40 12 8 22,5 10,4 45 14 10 24 14,2 48 16 10 24 14,2 48 20 11 25 18,2 50 +1°° 0 45° e1 319 h1 A-A A l1 DP - b A C utter with bore Tools d1 mm hank type cutters Shank mm d1 82000 S d1 D rills Design: Slim design for optimal chip ejection towards the dust extraction. n (max) = 24.000 rpm C lamping system K nives A Machine:CNC router H oggers For holding shank tools with clamping surface according to DIN 1835. Suitable for right-hand and left-hand rotation. A ccessories Application: S awblades HSK 63 F Weldon tool holder HSK 63F in acc. with DIN 69893 82000 HSKchuck S awblades HSK Plus tool holder for highest load D rills S hank type cutters For holding HSK Plus cutters Machine:CNC router A C utter with bore H oggers Application: Design: Screwed to the cutting tool a very high run-out accuracy of 0.003 - 0.01 mm is achieved. n (max) = 40.000 rpm HSK 63 F 82000 Shank mm A mm DT Order No. HSK 63 F 30,2 ◊ 10033898 HSK 63 F 50,2 ◊ 10033900 HSK 63 F 80,2 ◊ 10033902 Your advantages with HSK Plus tool holder. •Only minimal imbalance •For best cutting quality A ccessories DP - Tools C lamping system K nives •For up to 40,000 rpm 320 HSKchuck 82000 Machine:CNC router n (max) = 25.000 rpm C utter with bore d A mm d mm DT Order No. HSK 63 F 85 25 ◊ 40006600 Tools C lamping system K nives D rills S Shank mm DP - 82000 321 A ccessories A Design:The tool shanks do not require any locking screw. H oggers For high-precision clamping of shank tools with 25 mm cylindric shaft. For right-hand and left-hand rotation. hank type cutters Application: S awblades Hydrolic expansion chuck HSK 63 F in acc. with DIN 69893 HSKchuck 82000 Application: For high-precision clamping (warm shrinking) of wood-process- ing shank tools with cylindric shaft. Suitable for right-hand and left-hand rotation. A L1 L2 Machine:CNC router d1 D1 D 82000 Shank d1 mm A mm L1 mm L2 mm D mm D1 mm HSK 63F 10 75 36 49 32 24 Order No. ◊ 10156541 HSK 63F 12 75 41 49 32 24 ◊ 10156544 14 75 41 49 34 27 ◊ 10156545 HSK 63F 16 75 41 49 34 27 ◊ 10156547 HSK 63F 18 75 44 49 41 33 ◊ 10156548 HSK 63F 20 75 46 49 41 33 ◊ 10156549 HSK 63F 25 75 52 49 44 36 ◊ 10156550 Suitable shrinking unit available on demand. Tools DP A ccessories DT HSK 63F C lamping system K nives D rills S hank type cutters C utter with bore H oggers S awblades HSK 63 F Shrinking chuck HSK in acc. with DIN 69893 322 HSKchuck 81000 Application: For holding saw blades. The saw blade requires countersunk pin holes. For right-hand and left-hand rotation. Machine:CNC router n (max) = 9.000 rpm D Shank mm A mm D mm d1 mm L2 mm ph/pcd SW mm Order No. HSK 63 F 80 50 30 1,5 3/M6/40 41 10032284 HSK 63 F 80 60 30 2,0 4/M5/48 41 10156292 HSK 63 F 80 90 30 2,5 6/M8/75 41 10023989 HSK 63 F 80 120 30 2,5 6/M8/100 41 10034124 HSK 63 F 60 160 30 2,0 6/M8/140 46 10029752 Suitable circular saw blades D mm B mm b mm d mm Z Order No. 120 2,6 1,6 30 12F 003912330 120 2,6 1,6 30 30W 003912331 2,6 1,6 30 12F 003915330 D rills Other sizes or pitch circle diameters on demand. For D = 60 150 150 3,2 2,2 30 24W 003915331 150 3,2 2,2 30 36W 003915332 150 3,2 2,2 30 48W 003915333 250 3,5 2,2 30 24F 003925330 250 3,2 2,2 30 30W 003925331 For D = 90 250 3,2 2,2 30 48W 003925332 250 3,2 2,2 30 60W 003925333 250 3,2 2,2 30 80W 003925334 3,4 2,2 30 28F 003930330 C lamping system K nives For D = 50 For D = 120 300 300 3,2 2,2 30 36W 003930331 300 3,2 2,2 30 54W 003930332 300 3,2 2,2 30 72W 003930333 3,6 2,4 30 30F 003935330 For D = 160 350 350 3,5 2,4 30 54W 003935331 350 3,5 2,4 30 72W 003935332 350 3,5 2,4 30 84W 003935333 323 Tools 81000 S d1 ph/pcd hank type cutters C utter with bore With channel for data chips. DP - L2 Design: A ccessories A SW H oggers S awblades HSK 63 F Saw blade holder HSK 63F in acc. with DIN 69893 HSKchuck 81000 Application: S For direct mounting of saw blades or grooving cutters with countersunk pin holes. Hub thickness of 2,5 - 10 mm. With saw body or hub thicknesses of up to 3.5 mm a spacer (within the scope of supply) must be mounted. See picture. 6 L1 Machine:CNC router 10,5 L2 d1 Design: Depending on the clamping method the saw blade needs pin holes or counter sunk holes. n (max) = 11.000 rpm ph/pcd D 81000 Shank mm D mm d1 mm L2 mm L1 mm ph/pcd Design Order No. HSK 63 F 106 30 2,5 40 8/M5/90 without clamping cover 10149518 HSK 63 F 106 30 2,5 40 8/M5/90 with clamping cover 10157330 Suitable circular saw blades D mm B mm d mm ph mm Z Order No. 250 3,2 2,2 30 8/5,5/90 o.A. 48W 003925230 3,2 2,2 30 8/5,5/90 o.A. 60W 003925232 250 3,2 2,2 30 8/5,5/90 o.A. 80W 003925234 280 3,2 2,2 30 8/5,5/90 o.A. 48W 003928230 280 3,2 2,2 30 8/5,5/90 o.A. 60W 003928231 280 3,2 2,2 30 8/5,5/90 o.A. 80W 003928232 300 3,2 2,2 30 8/5,5/90 o.A. 36W 003930230 300 3,2 2,2 30 8/5,5/90 o.A. 54W 003930231 300 3,2 2,2 30 8/5,5/90 o.A. 75W 003930232 350 3,5 2,4 30 8/5,5/90 o.A. 54W 003935230 350 3,5 2,4 30 8/5,5/90 o.A. 72W 003935231 350 3,5 2,4 30 8/5,5/90 o.A. 84FT 003935233 350 3,5 2,4 30 8/5,5/90 o.A. 84W 003935232 DP A ccessories b mm 250 Tools C lamping system K nives D rills S hank type cutters C utter with bore H oggers S awblades HSK 63 F Saw blade holder for Homag 324 HSKchuck 81000 MACHINE: Moulders with HSK 85 interface, e.g. Weinig Design: Distortion lock achieved by pinning and screwing. H oggers For holding boring tools. The admissible speed of the boring tools must be observed. C utter with bore Application: A L2 d1 S awblades Arbor holder Powerlock ø85 ph / Thread DT Order No. HSK 85 30 40 26 48 2x6,0 2xM6 ◊ 10156237 HSK 85 30 60 26 48 2x6,0 2xM6 ◊ 10156238 HSK 85 30 80 26 48 2x6,0 2xM6 ◊ 10156239 HSK 85 30 130 26 48 2x6,0 2xM6 ◊ 10156240 HSK 85 30 170 26 48 2x6,0 2xM6 ◊ 10156241 HSK 85 40 40 26 54 2x6,0 2xM6 ◊ 10156242 HSK 85 40 60 26 54 2x6,0 2xM6 ◊ 10156243 HSK 85 40 80 26 54 2x6,0 2xM6 ◊ 10156245 HSK 85 40 100 26 54 2x6,0 2xM6 ◊ 10156247 HSK 85 40 130 26 54 2x6,0 2xM6 ◊ 10156248 HSK 85 40 170 26 54 2x6,0 2xM6 ◊ 10156249 HSK 85 40 180 26 54 2x6,0 2xM6 ◊ 10156250 HSK 85 40 240 26 54 2x6,0 2xM6 ◊ 10156251 HSK 85 50 40 26 64 2x6,0 2xM6 ◊ 10156252 HSK 85 50 60 26 64 2x6,0 2xM6 ◊ 10156253 HSK 85 50 80 26 64 2x6,0 2xM6 ◊ 10156254 HSK 85 50 100 26 64 2x6,0 2xM6 ◊ 10156255 HSK 85 50 130 26 64 2x6,0 2xM6 ◊ 10156256 HSK 85 50 150 26 64 2x6,0 2xM6 ◊ 10156257 HSK 85 50 170 26 64 2x6,0 2xM6 ◊ 10156258 HSK 85 50 180 26 64 2x6,0 2xM6 ◊ 10156259 HSK 85 50 240 26 64 2x6,0 2xM6 ◊ 10156260 2-piece draw bolt for cutters included in the scope of delivery The following variants are available on demand: • as HSK 85 with grooves (torque support) • with keys for heavy tools • with hydraulic clamping for optimal concentricity tolerance. 325 hank type cutters ph S TK mm D rills A mm C lamping system K nives L2 mm Tools 81000 d1 mm DP - d hrea ph/T Shank A ccessories TK ph SKchuck 82000 S awblades SK Collet chuck SK in acc. with DIN 69871 D rills S hank type cutters Machine:CNC router A C utter with bore H oggers Application:Clamping shank tools with cylindrical shaft. Suitable for right-hand and left-hand rotation Design: Pull stud, depending on machine manufacturer. Clamping nut ball bearing mounted, collets can therefore be mounted and removed easily. n (max) = 24.000 rpm d1 D 82000 Shank mm A mm D/Thread mm d1 mm for collet chucks no. DT Order No. SK 30 56 63/M50 6-26 472 E (up to 25 mm) ◊ 10014242 SK 30 70 60/M48 6-25,4 462 E (up to 25 mm) ◊ 10014643 SK 30 81 60/M48 6-25,4 462 E (up to 25 mm) ◊ 10014645 SK 40 79 60/M48 6-25,4 462 E (up to 25 mm) ◊ 10014517 Delivery without hook wrench and collet. Pull stud DIN 69872 is supplied together with SK 40. For SK 30 we need the machine details. Please observe the minimum clamping length on the shanks of the tools. A ccessories DP - Tools C lamping system K nives For pull studs and hook wrenches see chapter “Accessories”. For collet chucks see pages 332-333: 326 SKchuck 82000 Application: For clamping shank tools with cylindric shaft Suitable for right-hand and left-hand rotation Machine: CNC router specifically designed for Morbidelli / SCM C utter with bore n (max) = 24.000 rpm d1 D A mm D/Thread mm d1 mm for collet chucks no. DT Order No. SK 30 55 50/M40 5-20,0 470 E (up to 20 mm) ◊ 10002396 SK 30 70 60/M48 6-25,4 462 E (up to 25 mm) ◊ 10002397 Delivery without hook wrench and collet Delivered with pull stud 10006131 for SCM / Morbidelli Please observe the minimum clamping length on the shanks of the tools D rills S Shank mm Tools C lamping system K nives For hook wrench see chapter “Accessories”. For collet chucks see pages 332-333. DP - 82000 hank type cutters 327 A ccessories A Design:Clamping nut ball bearing mounted. Collets can therefore be mounted and removed easily. H oggers S awblades SK 30 Collet chuck With key-type rim for Morbidelli / SCM SKchuck 81000 S awblades SK 40 Arbor SK 40 in acc. with DIN 69871 S hank type cutters For holding boring tools. The admissible speed of the boring tools are to be observed. Machine:CNC router Very high clamping force and optimal safety by means of M16 draw bolt with rigid cover disc. Anti-turn locking device by means of feather keys. A Design: L2 C utter with bore H oggers Application: d1 81000 Shank mm d1 mm L2 mm A mm DKN mm weight kg Order No. SK 40 30 60 43 8x2 1,5 ◊ 10014228 SK 40 30 80 43 8x2 1,6 ◊ 10014230 SK 40 30 100 43 8x2 1,75 ◊ 10014229 DP - Tools C lamping system K nives D rills Draw bolt, pull stud and cover disc are in the scope of delivery. A ccessories DT 328 SKchuck 82000 n (max) = 24.000 rpm A d1 82000 Shank mm d1 mm A mm DT Order No. SK 40 16 63 10013536 SK 40 20 63 ○ ○ 10013538 H oggers Design: Slim design for optimal chip ejection towards the dust extraction. C utter with bore Machine:CNC router hank type cutters For holding boring tools. The admissible speed of the bor- ing tools are to be observed Suitable for right-hand and left-hand rotation S Application: S awblades SK 40 Weldon tool holder SK 40 in acc. with DIN 69871 D rills SK 40 holders are delivered including pull stud (DIN 69872). e1 mm 0 -1 h1 mm h6 b1 mm +0,05 0 h13 i1 mm +2 0 6 4,2 18,0 4,8 36 8 5,5 18,0 6,6 36 10 7,0 20,0 8,4 40 12 8,0 22,5 10,4 45 14 10,0 24,0 14,2 48 16 10,0 24,0 14,2 48 20 11,0 25,0 18,2 50 b e1 d1 A l1 329 h1 A-A A DP - Tools +1°° 0 45° A ccessories d1 mm C lamping system K nives Clamping surface according to DIN 1835 B. 82000 SKchuck S awblades SK Plus tool holder for highest load For holding SK Plus cutters Machine:CNC router A Design: Screwed to the cutting tool a very high run-out accuracy of 0.003 - 0.01 mm is achieved. n (max) = 40.000 rpm SK 30 82000 A D rills S hank type cutters C utter with bore H oggers Application: Shank mm A mm DT Order No. SK 30 33,3 ◊ 10034362 SK 30 33,3 ◊ 10034013 SK 40 33,3 ◊ 10034015 Your advantages with SK Plus tool holder. SK 40 •Only minimal imbalance •For best cutting quality A ccessories DP - Tools C lamping system K nives •For up to 40,000 rpm 330 Accessories Shank mm DT Order No. SK 40 ◊ 10002577 HSK 63 F ◊ 10002580 HSK 85 (Powerlock) ◊ 40015764 abors and with saw blade flanges. for chucks Order No. HSK 25 10163751 HSK 32 (C3) 10163752 HSK 40 (C4) 10163753 HSK 50 (SK 30) 10163754 HSK 63 (SK 40) 10163755 HSK 80 10163756 SK 50 10163757 HSK 100 10163758 331 Tools DP - Fast and safe mounting of tools in chucks, on cutter Application: A ccessories Accessories Masterclamp C lamping system K nives D rills S Installation devices for other interfaces on demand. C utter with bore Design:Easy tensioning by means of clamping lever H oggers Safe clamping of the tool set when mounted or removed and also during the change of knives with TOK tools hank type cutters Application: S awblades Accessories Mounting rack for all standard holders Precisioncollet 82000 S awblades Precision collet Short design, clamping tolerance 1.0 mm, clamping range 6 to 26 mm A ccessories DP - Tools C lamping system K nives D rills S hank type cutters short desing Application: For collet chucks Design: 16-fold slotted L1 C utter with bore H oggers 8° d1 D 82000 NEW NEW NEW NEW NEW NEW NEW NEW NEW NEW NEW D mm d1 mm L1 mm Clamping range mm Clamping tolerance mm Order No. 17 17 17 17 17 17 17 17 26 26 26 26 26 26 26 26 26 33 33 33 33 33 33 33 33 33 33 20 6 7 8 10 12 13 16 18 19 20 25 26 3 4 5 6 7 8 9 10 3 4 5 6 8 10 12 14 16 6 7 8 10 12 13 14 16 18 19 40 46 46 46 46 46 46 46 46 46 46 46 46 27 27 27 27 27 27 27 27 34 34 34 34 34 34 34 34 34 40 40 40 40 40 40 40 40 40 40 33 41 41 41 41 41 41 41 41 41 41 41 41 up to 10 (426 E) ER 16 up to 10 (426 E) ER 16 up to 10 (426 E) ER 16 up to 10 (426 E) ER 16 up to 10 (426 E) ER 16 up to 10 (426 E) ER 16 up to 10 (426 E) ER 16 up to 10 (426 E) ER 16 up to 16 (430 E) ER 25 up to 16 (430 E) ER 25 up to 16 (430 E) ER 25 up to 16 (430 E) ER 25 up to 16 (430 E) ER 25 up to 16 (430 E) ER 25 up to 16 (430 E) ER 25 up to 16 (430 E) ER 25 up to 16 (430 E) ER 25 up to 20 (470 E) ER 32 up to 20 (470 E) ER 32 up to 20 (470 E) ER 32 up to 20 (470 E) ER 32 up to 20 (470 E) ER 32 up to 20 (470 E) ER 32 up to 20 (470 E) ER 32 up to 20 (470 E) ER 32 up to 20 (470 E) ER 32 up to 20 (470 E) ER 32 up to 20 (470 E) ER 32 up to 25 (472 E) ER 40 up to 25 (472 E) ER 40 up to 25 (472 E) ER 40 up to 25 (472 E) ER 40 up to 25 (472 E) ER 40 up to 25 (472 E) ER 40 up to 25 (472 E) ER 40 up to 25 (472 E) ER 40 up to 25 (472 E) ER 40 up to 25 (472 E) ER 40 up to 25 (472 E) ER 40 up to 25 (472 E) ER 40 3 4 5 6 7 8 9 10 3 4 5 5-6 7-8 9-10 11-12 13-14 15-16 5-6 6-7 7-8 9-10 11-12 12-13 13-14 15-16 17-18 18-19 19-20 5-6 6-7 7-8 9-10 11-12 12-13 15-16 17-18 18-19 19-20 24-25 25-26 10174703 10174704 10174706 10174972 10174973 10174974 10174975 10174976 10174965 10174967 10174971 10017107 40002352 40002786 40002353 40003740 40002354 10002467 10002468 10002469 10002470 10002471 10002472 10002473 10002474 10002475 40013253 10002476 40002325 40013254 10002480 10002481 10002482 10002483 10002484 10002485 10002486 10002487 10002488 10002489 332 Precisioncollet 82000 Design: 12-fold slotted H oggers For collet chucks Clamping tolerance mm Order No. 22,65 5,0 40 up to 16 (415 E) 4,5-5,0 40011175 22,65 6,0 40 up to 16 (415 E) 5,5-6,0 40002318 22,65 6,5 40 up to 16 (415 E) 6,0-6,5 10002424 22,65 8,0 40 up to 16 (415 E) 7,5-8,0 40002320 22,65 9,5 40 up to 16 (415 E) 9,0-9,5 10017090 22,65 10,0 40 up to 16 (415 E) 9,5-10,0 10002425 22,65 12,0 40 up to 16 (415 E) 11,5-12,0 40002322 22,65 13,0 40 up to 16 (415 E) 12,5-13,0 10002426 22,65 14,0 40 up to 16 (415 E) 13,5-14,0 40005333 22,65 16,0 40 up to 16 (415 E) 15,5-16,0 10002427 32,9 3,0 52 up to 25 (462 E) 2,5-3,0 40003064 32,9 4,0 52 up to 25 (462 E) 3,5-4,0 40002435 32,9 5,0 52 up to 25 (462 E) 4,5-5,0 40002305 32,9 6,0 52 up to 25 (462 E) 5,5-6,0 10002432 32,9 6,5 52 up to 25 (462 E) 6,0-6,5 10002433 32,9 8,0 52 up to 25 (462 E) 7,5-8,0 40002306 32,9 9,5 52 up to 25 (462 E) 9,0-9,5 10002434 32,9 10,0 52 up to 25 (462 E) 9,5-10,0 10002435 32,9 12,0 52 up to 25 (462 E) 11,5-12,0 10002436 32,9 13,0 52 up to 25 (462 E) 12,5-13,0 10002437 32,9 14,0 52 up to 25 (462 E) 13,5-14,0 40002308 32,9 16,0 52 up to 25 (462 E) 15,5-16,0 10002438 32,9 18,0 52 up to 25 (462 E) 17,5-18,0 40002311 32,9 19,0 52 up to 25 (462 E) 18,5-19,0 10002439 32,9 20,0 52 up to 25 (462 E) 19,5-20,0 10013431 32,9 25,0 52 up to 25 (462 E) 24,5-25,0 40002313 32,9 25,4 52 up to 25 (462 E) 25,0-25,4 10002440 333 S Clamping range mm D rills L1 mm C lamping system K nives d1 mm Tools D mm DP - 82000 A ccessories d1 D hank type cutters C utter with bore Application: L1 10:1 S awblades Precision collet Clamping tolerance 0,5 mm, Clamping range 5-25,4 mm Precisioncollet 39191 S awblades Accessories for collet chucks M12 M12 Ø8 Ø12 3 M12 Ø8 Ø12 4 24 M12 Ø13 5 Ø9 3.5 1.5 M10 Ø6.5 Ø8.5 6 22 DT Order No. 1 IMA, Maka, Reichenbacher, Weeke, Busellato, etc. 13/9 - M12 10006129 2 IMA, Maka, Reichenbacher, Stegherr, etc. 19/14 - M16 10006130 3 Biesse up to Bj. 09/1992 12/8 - M12 ◊ 10006133 4 Biesse ab Bj. 09/1992 Masterwood (HSD-Motoren) 12/8 - M12 ◊ 10006134 5 Alberti, Masterwood (Colombo-Motoren) 13/9 - M12 ◊ 10006136 6 Morbidelli, SCM 8,5/6,5 - M10 ◊ 10006131 7 Shoda 11/7 -M12 ◊ 10006132 8 Heian 13,7/8,9 - M12 JiS B 6339 ◊ 10006137 9 CMS 12,8/9 - M12 ◊ 10006135 M12 Ø11 Ø7 M12 Ø8.9 Ø13.7 Ø9 M12 28 Ø12.8 D rills 8 24 C lamping system K nives Dimension mm 24 9 Tools Machine 24 23 DP - AB Nr. M16 Ø19 Ø14 26 S hank type cutters 2 7 A ccessories Pull stud 24 40° C utter with bore H oggers 1 Ø9 Ø13 39191 Tightening nut and hook wrench Thread D mm DT Order No. Tightening nut, ball bearing mounted M30x1,5 43 ◊ 10005969 Tightening nut, ball bearing mounted M40x1,5 50 40012692 Tightening nut, ball bearing mounted M48x2,0 60 10005970 Tightening nut, ball bearing mounted M50x1,5 63 40004939 Tightening nut, ball bearing mounted ER16 mini M19x1 10175069 Hook wrench für M30x1,5 40/42 Hook wrench für M40x1,5 45/50 Hook wrench für M48x2,0 für M50x1,5 58/62 ◊ 10006111 Hook wrench ER16 mini M19x1 ◊ 10174977 Denomination 334 ◊ 10006109 10006110 Sawblade holder 81000 Shank mm D mm d1 mm L2 mm L1 mm SW mm ph/pcd DT Order No. 25 50 22 3 70 46 4/M6/36 ◊ 10022138 25 56 30 4 71 46 4/M6/42 ◊ 10014763 20 60 30 4 90 46 4/M6/48 ◊ 40013258 25 60 30 4 90 46 4/M6/48 ◊ 10002501 C utter with bore n (max) = 11.000 rpm hank type cutters D rills Other sizes or pitch circle diameters on demand. D mm B mm b mm d mm Z Order No. 150 2,6 1,6 30 12F 003915231 150 3,2 2,2 30 24W 003915232 150 3,2 2,2 30 36W 003915233 150 3,2 2,2 30 48W 003915234 180 2,8 1,8 30 12F 003918230 180 3,2 2,2 30 30W 003918233 180 3,2 2,2 30 42W 003918235 180 3,2 2,2 30 54W 003918232 200 2,8 1,8 30 16F 003920231 200 3,2 2,2 30 36W 003920234 200 3,2 2,2 30 48W 003920236 200 3,2 2,2 30 60W 003920238 C lamping system K nives Suitable circular saw blades Tools 81000 Design:The tool / saw blade is clamped directly by means of 4 counter sunk screws. DP - d1 ph/pcd D 335 A ccessories L2 Machine:CNC router S For direct mounting of saw blades or grooving cutters with countersunk pin holes. Hub thickness of 2 - 10 mm. With saw body or hub thicknesses of up to 3.5 mm a spacer (within the scope of supply) must be mounted. See picture. L1 Application: H oggers S awblades Sawblade holder with cylindric shank 81000 Sleeve S awblades Reducing sleeve with collar S hank type cutters d2 L1 d1 L2 C utter with bore H oggers Application:To be applied in pairs for reducing the bore of cutters and knife heads. D 81000 D mm d1 mm L2 mm L1 mm Order No. 59 30 35 15 20 10017296 58 30 40 15 20 10014724 64 35 40 15 20 10014726 64 40 50 15 20 10014727 DP - Tools C lamping system K nives D rills Further dimensions on demand. A ccessories d2 mm 336 81000 Sleeve For mounting scoring saws on standard spindles Homag / IMA d=30 AL L1 d1 mm d2 mm ph/pcd L1 mm L2 mm AL mm Order No. 108 30 DKN 65 6/M5/90 95 2 63 003100014 DP - Tools C lamping system K nives D rills S D mm 337 A ccessories 81000 hank type cutters C utter with bore d2 TK D d1 Application: H oggers S awblades Sleeve for scoring blades 81000 Sleeve S awblades Sleeve for scoring blades and hoggers For mounting hoggers on standard spindles Homag / IMA d=30 L2 SW d1 d2 TK D AL L1 81000 D mm d1 mm d2 mm ph/pcd L1 mm L2 mm SW AL mm Order No. 115 35 DKN 80 8/M8/100 90 16,2 55 63,0 003300002 A ccessories DP - Tools C lamping system K nives D rills S hank type cutters C utter with bore H oggers Application: 338 81000 Sleeve 110 30DKN 110 35DKN 147 35DKN d1 mm d2 mm TK mm Number of bolts L1 mm 50 80 3 63 L2 mm A mm DT Order No. 63 ◊ 003811030 50 80 3 63 63 ◊ 003811035 75 66 105 3 90 20 70 ◊ 003814735 66 105 3 90 20 70 ◊ 003814746 130 4 60 60 ◊ 003816035 150 4 90 72,5 ◊ 003819246 147 40DKN 75 160 35DKN 80 192 40DKN 80 66 17,5 Fixmatic H (Hydro) available on demand. D Spare clamping flanges D mm for mountig rhs/lhs Order No. 110 between clamping flange (inside) rhs or lhs 003811049 110 in front of the clamping flange (externally) lhs 003811051 110 in front of the clamping flange (externally) rhs 003811052 Spare parts Denomination Order No. Pneumatik spiral hose 003800005 339 C utter with bore D rills d mm C lamping system K nives D mm hank type cutters Design:The tools are clamped pneumatically with compressed air. Tools d2 d1 TK D d 81000 Double end tenoner DP - Machine: L2 A ccessories A S Application: For quick change of cutters. Suitable for clockwise and anti-clockwise rotation. Bayonet holder necessary on the tool. L1 H oggers S awblades Quick clamping system Fixmatic P 81000 Sleeve d d1 D AL Application: For mounting hoggers or cutting tools on the standard HF spindle with hexagon. Machine: Double end tenoner Design:Case-hardened hydraulic clamping elements with closed pres- sure system. The spindle fixture is not included in the scope of delivery. L1 10138922 81000 hank type cutters C utter with bore H oggers S awblades Hydro sleeve Hexagon for hoggers and cutting tools d mm d1 mm L1 mm AL mm DT Order No. 120 40 60 92 68 ◊ 10138922 120 40 60 96 68 ◊ 10151628 120 40 80 92 25/35 ◊ 10138919 D rills d d1 D S AL D mm Accessories: 10151628 DP A ccessories Denomination Order No. spindle fixture for 10138922 + 10151628 10104476 spindle fixture for 10138919 10104478 d d1 AL D d1 AL Tools C lamping system K nives L1 L1 10138919 340 81000 Sleeve For mounting saw blade and cutter. Can be shifted and positioned freely on the arbor. Machine: For saw arbors (e.g. Paul machines) AL C utter with bore d1 mm d2 mm D mm L1 mm AL mm DT Order No. 100 120 153 60/75 25 40015531 100 120 153 47/59 27 100 120 153 41/53 21 ○ ○ ○ 10133148 Tools C lamping system K nives D rills 10141520 DP - 81000 hank type cutters d1 d2 D Design:Case-hardened hydraulic clamping elements with closed pressure system and integrated clamping ring. H oggers Application: S L1 341 A ccessories L1 S awblades Hydro sleeve With clamping ring