“Anaerobic Respiration Lab” Introduction Ethanol is a fuel produced

advertisement

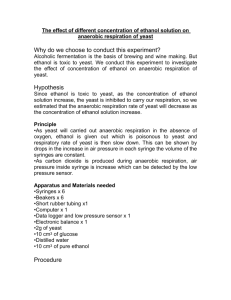

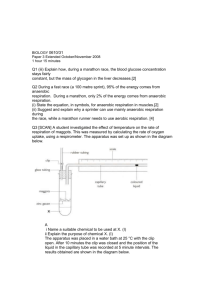

“Anaerobic Respiration Lab” Introduction Ethanol is a fuel produced by the fermentation (anaerobic respiration) of starch. In the auto industry, companies make 13.5 billion gallons of ethanol, which is roughly ten percent of the nation’s motor fuel supply. Fermentation or anaerobic respiration is a method that is used by yeast cells to produce energy, while producing the ethanol byproduct. Harnessing the natural power of yeast and anaerobic respiration, fuel companies produce billions of gallons of valuable ethanol. You will take on the role of biologist to run tests that determine the ideal conditions for anaerobic respiration and ethanol production. If yeast produce more ethanol, the price of gas will decline and you will be helping the company boost productivity and profits. Such a great accomplishment will result in a large bonus to your paycheck. As a researcher you know that yeast metabolize sugars and carbohydrates through anaerobic respiration. This chemical reaction yields not only ethanol but carbon dioxide. The amount of carbon dioxide produced is directly proportional to the amount of ethanol made through fermentation. The structures of the sugars may impact the efficiency of fermentation. The structure of each sugars you may test are illustrated below. Experimental Question: How do different carbohydrates such as table sugar (sucrose) and glucose affect the rate of ethanol production by the anaerobic respiration of yeast? Hypothesis: Procedure 1. In a dosing syringe, obtain exactly 1.5 mL of the yeast solution. If you are using a larger syringe obtain 5 mL of yeast solution. Make sure you are consistent with the volume of yeast solution you use for each different type of sugar. 2. Attach an empty dosing syringe with a tube to the syringe containing yeast solution. 3. Repeat steps 1-2 with at least one different type of sugar. 3. Place the syringes containing the yeast in a warm water bath. 4. Wait and record the total volume of Carbon Dioxide produced by anaerobic respiration every 5 minutes. This is done by measuring how much the plungers of both syringes are pushed out. Remember, to consider that you had 5 mL of yeast solution to begin. 5. Continue to take measurements for the remainder of class. Data: Create a table, and graph to represent your data. Your graph and table should show the relationship between the rates of anaerobic respiration in yeast that consume different types of sugars. Conclusions 1. Make your recommendations on what sugar should be used to maximize the production of ethanol. Refer to your data to support your conclusions. 2. Summarize the process of anaerobic respiration. 3. Predict any sources of human or experimental error that may have affected your results. 4. Compare and contrast anaerobic and aerobic cellular respiration. 5. How does anaerobic respiration differ in our muscles and yeast? Extension 1. How quickly did each yeast solution metabolize the sugar into ATP and Ethanol? For each molecule of carbon dioxide, the yeast also produce one molecule of ethanol. Use your last data point and the equation below to determine the rate of metabolism the sugars tested. PV = NRT P = Pressure (assume to be the barometric pressure of 1 atmosphere) V = Volume of Gas (mL of carbon dioxide captured in the syringes) N = Number of Molecules (moles of carbon dioxide, 1 mole is 6.02X1023 molecules) T = Temperature (assume the water bath to be 100⁰F = 310⁰K) R = Gas Constant (82.05 mL◦atm/mol◦K) Example of Calculation assuming the yeast generated 10 mL of carbon dioxide over 20 minutes. N = PV/RT = 1atm◦10mL / (82.05 mL◦atm/mol◦K)◦310K = 3.9x10-4 mol CO2 = 0.00039 mol CO2 ◦ 6.02X1023 molecules/mol= 2.36x1020 molecules of carbon dioxide Over 20 minutes the yeast made 2.36x1020 molecules of carbon dioxide. In other words the yeast made 1.18x1019 molecules of carbon dioxide each minute. This is equivalent to the number of ethanol molecules produced each minute.