VAPOR PRESSURE AS A FUNCTION OF

advertisement

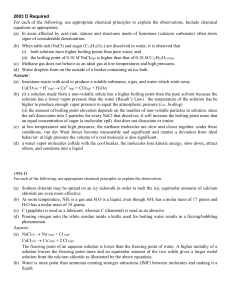

VAPOR PRESSURE AS A FUNCTION OF TEMPERATURE Objectives: (1) Observe and measure the change in the vapor pressure (dependent variable) as a function of temperature (independent variable). (2) Analyze the experimental data to determine the normal boiling point and the heat of vaporization, ΔHvap, using the Clausius-Clapeyron equation. This laboratory covers material presented in section 11.8 of the 9th Ed. of the Chang text. Introduction: The quantity of vapor above a liquid in a closed system increases with the temperature of the system. The quantity of vapor can be measured as the vapor pressure of the system. This relationship is pictorially shown in Figure 1. Figure 1. Pictorial representation of the increased quantity of gas above a liquid as the system is heated. The relationship between vapor pressure and temperature can be understood in terms of molecules in the liquid escaping the attractive forces of the liquid to enter the gas phase. A measure of the liquid’s molecular attraction is the heat of vaporization (ΔHvap). A large ΔHvap would indicate strong attractive forces between molecules in the liquid phase. At a low temperature few molecules have enough energy to overcome the intermolecular attractions of the liquid. As temperature increases, a greater number of molecules have enough energy to escape the intermolecular forces of the liquid. In Figure 2 the kinetic energy distribution for a low temperature sample is shown by the blue trace and the blue shaded area indicates the fraction of molecules with enough energy to escape from the liquid. The red kinetic energy distribution is for a warmer sample and the larger red shaded area indicates the number of molecules with enough energy to escape the molecular attractions of the liquid at the higher temperature. Figure 2. The plot shows the kinetic energy distribution for molecules at a low temperature (blue trace) and at a higher temperature (red trace). As temperature increases, a greater fraction of the molecules have enough energy to escape the molecular attractions of the liquid. For liquids the vapor pressure as a function of temperature has an exponential behavior as shown in Figure 3. Figure 3. Plot of vapor pressure vs. temperature of a sample. The exponential behavior of vapor pressure (P) as a function of temperature (T) is given by the exponential function: −ΔH RT (1) P = Ae( vap ) A in the expression is an experimental constant that can be related to the normal boiling point, ΔHvap is the heat of vaporization of the liquid, and R is the gas constant, R = 8.314 J/(K mol). € The author of your text indicates a relationship between pressure and temperature that does not contain an exponential term. To remove an exponent from an expression the log function (log or ln) can be used. Taking the natural log (ln) of both sides of equation (1) gives: ΔHvap (2) RT This can be made to look like a straight-line equation similar to textbook equation 11.2 by rearranging terms. ln(P) = ln(A) − € ln(P) = € y = −ΔH vap 1 + ln( A) R T m x + b The textbook also nicely points out that this is the equation of a straight line if you plot ln(P), y, vs. 1/T, x, and the slope, m, is equivalent to −ΔHvap/R. This equation is the Clausius-Clapeyron equation named after the German physicist Rudolf Clausius (1822 - 1888) and the French engineer Emil Clapeyron (1799 - 1864). This week in lab you will fit a set of vapor pressure vs. temperature data to the ClausiusClapeyron equation to determine the heat of vaporization of an unknown liquid, shown in Figure 4. Figure 4. The linear relationship between ln(P) vs 1/T comes from the ClausiusClapeyron equation. Experimental Procedure: In measuring vapor pressure vs. temperature you will take advantage of the definition of boiling. Recall that boiling is defined as the temperature of liquid at which the vapor pressure is equal to the atmospheric pressure. You will reduce the pressure above a liquid using the vacuum system in the hood. By recording the temperature and pressure at which the liquid boils for several different external pressures, the plot in Figure 4 will be created for your unknown liquid. You must have on safety glasses for this experiment. Glass under vacuum is potentially hazardous. A small crack in a glass vessel can result in an implosion of the vessel, dispersing small pieces of glass over a large area. Become familiar with the apparatus shown in Figure 5 and assembled in the hood. The fist thing to do is check the apparatus for air leaks. Fixing these leaks can be tedious. Figure 5. A schematic of the vacuum distillation apparatus Turn on the vacuum at the hood by opening the vacuum valve all the way and then close it about half a turn. Open the 3-way valve so that there is a pressure drop in the system. The hood vacuum should pump the system to about 20 inches of Hg (in Hg). Close the 3-way valve so that the system is isolated from the vacuum. This valve placement shown in Figure 5 will isolate the system from the atmosphere as well. Watch the gauge. It should remain stable, losing no more than 1 in Hg in two minutes. If the system is leaking you have some work to do. Finding leaks in vacuum systems is challenging. Obtain some vacuum grease from the TA and apply a small amount to the joints of the still. Reassemble the apparatus and try the vacuum test again. If a leak persists, discuss possible sources with your partners. Take pieces apart and reconstruct the system so that individual elements can be checked. If the system is vacuum tight, practice bleeding air slowly into the system to familiarize yourself with the 3-way stopcock. Figure 6 shows the three operational modes of the stopcock. Work with it until you are able to increase and decrease the pressure in your apparatus by one inch of Hg. It will take a while to master this. Keep practicing and let everyone in the group have a turn. Figure 6. Setting on the 3-way stopcock. Once your group is comfortable with controlling the pressure of your apparatus, vent the system to the atmosphere and disconnect thermometer joint. Use a long-stem funnel to fill the round bottom flask in the heating mantel with 200 ml of the liquid to be studied. Add to the round bottom flask a stir bar. Fill the plastic container around the collection flask 2/3 full with water and ice to make a bath. Gently apply a vacuum to the system with the 3-way stopcock. Eventually open the stopcock to full vacuum. The system should pump to about 20 in Hg on the vacuum gauge. The liquid in the round bottom flask is likely to bubble as the vacuum is initially applied, this is not boiling, but rather the outgassing of air dissolved in the liquid. This is the same phenomenon as the bubbles released in a soda pop when a bottle is first opened. This is Henry’s law in action. Even though this looks like boiling, bubbles forming in a liquid, it is important to note the difference. Boiling is the formation of bubbles composed of gas molecules of the liquid (ex. acetone), while degassing consists of gas bubbles composed of N2 or CO2. The outgassing in your sample will soon end as the dissolved gas is removed from the liquid. Unless it is surprisingly warm in the lab during the experiment, the liquid will not boil until the temperature is elevated. Turn on the heater on. Data collection can now begin. Create a data table in your lab notebook to record boiling temperatures and vacuum gauge pressures. Wait and watch as the temperature rises in the liquid. It will probably take several minutes for the liquid temperature to rise to its boiling point. Once boiling in the liquid begins, record the temperature when the vapor of the liquid completely covers the bulb of the thermometer. After recording the boiling temperature also record the pressure of the system. After the first data point is recorded (this will be the lowest pressure) raise the pressure in the system from 20 in Hg to something between 18 and 16 in Hg. Isolate the system from vacuum at the new pressure by setting the stopcock in the closed position. Boiling will stop as the pressure is increased. This is because the vapor pressure is now less than the external pressure. Again allow the system to warm until the liquid begins boiling. Record your second temperature and the vapor pressure. The system may leak a little during this time. A few in Hg won’t matter and you can always pump the system back down to the desired pressure. If the system leaks substantially (> 5 in Hg) while the sample is heating, you should stop the experiment and do some further leak tests. After recording your second temperature and vapor pressure data point, bleed air into the system to again raise the pressure by 3 or 4 in Hg. Again, boiling will stop and you should wait to measure the new boiling temperature. Repeat the pressure increases and sample warming until a final gauge pressure of 3 or 4 in Hg is reached in the system. This should give you six or seven temperature and. vapor pressure data points. After collecting the last data point, disconnect the tubing from the sidearm of the collection flask. Continue to heat the solution so that a boiling point at the current atmospheric pressure can be measured. Today’s atmospheric pressure can be read from a barometer or be obtained from your TA. The boiling point at atmospheric pressure constitutes your final data point. Place the liquid studied into the appropriate waste beaker. Be sure to pour the extra liquid from the collection beaker into the waste beaker as well. Data Analysis: A plot of ln(vapor pressure) vs. 1/T must be made to determine the heat of vaporization of your liquid. To make this plot in Excel, create the table shown in Figure 7. You should use the formula feature in Excel to perform calculations. A formula in Excel is entered by using an = sign at the beginning of the expression. The formulas needed are shown in row 2 of the example spreadsheet in Figure 7. Figure 7. Example spreadsheet used to make the plot of ln(P) vs. 1/T. A formula can be made to fill a column by clicking and dragging the cell from the lower right hand corner down the row. The lower arrow in Figure 8 shows where to click and drag in the formula cell. Figure 8. This figure shows how to fill a column with a repeated formula. In Figure 7 column (E) is the vapor pressure of the liquid in the familiar units of mmHg. This formula is a little unusual. The vacuum gauge reads as if it were the height of a mercury column in a manometer—the reading tells how much less the pressure inside the system is than the atmospheric pressure. Therefore, the conversion in cell E2 (=740-B2*25.4) is required. In your formula, use today’s atmospheric pressure (in mmHg) in place of the value “740” in the formula. Once your spreadsheet has a similar appearance to the sheet in Figure 7, make a plot of ln(VP) vs 1/T in the following way. To plot the data, click and drag over the 1/T column to highlight the column and then with the Ctrl button pressed drag on the ln(VP) column. Each column should be highlighted as in Figure 7. To plot this data click on the Chart Wizard Icon, open. . The wizard dialogue box, Figure 9, will Figure 9. A screen capture of the Excel spreadsheet showing the Chart Wizard dialogue box. In the Chart Wizard select XY (Scatter) and points only. Complete the wizard by completing the appropriate items. Then click Finish. The resulting plot should look similar to the following, Figure 10. Clausius Clapyeron Plot 6.8 ln(vap. pres.) 6.6 y = -4869.9x + 21.281 6.4 Figure 10. View of the Clausius-Clapeyron plot. 6.2 6 5.8 5.6 5.4 0.003 0.00305 0.0031 0.00315 0.0032 0.00325 1/Temp (1/K) The linear fit to the data is done in Excel by selecting “Add Trendline”. In the trendline dialog box select the type as “Linear” and then click on the Options tab. In the Options box, click the “Display Equation on Chart” feature. The best-fit line will be given to you in slope-intercept form. Expect a slope similar to the slope given in Figure 10. Save this Plot to your network drive. You will need it for your lab assignment. From the slope, determine the heat of vaporization (ΔHvap) in kJ/mol. After making the final calculations in your notebook turn in your duplicate notebook pages.