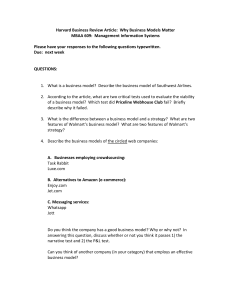

Standards for Suppliers Manual

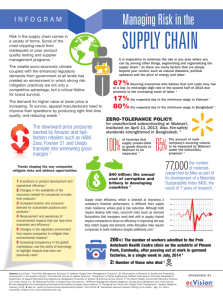

advertisement