What New Buyers Need to Know - China Sourcing Information Center

advertisement

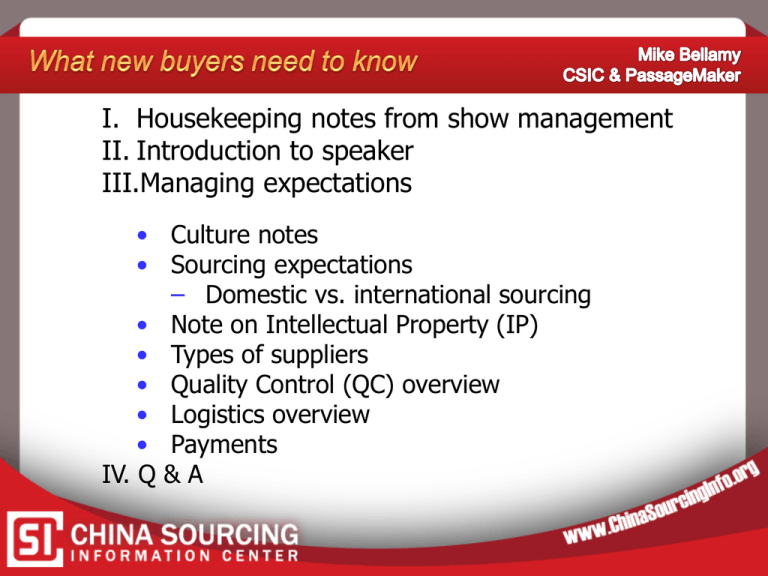

I. Housekeeping notes from show management II. Introduction to speaker III.Managing expectations • Culture notes • Sourcing expectations – Domestic vs. international sourcing • Note on Intellectual Property (IP) • Types of suppliers • Quality Control (QC) overview • Logistics overview • Payments IV. Q & A www.PSSchina.com Supply Chains Serviced Our clients are direct suppliers to the following retailers and corporations: CSIC is a not-for-profit organization that exists to help educate, develop, and advance the China sourcing professional. The following resources are available free of charge to the public: » China Sourcer e-Magazine » Video Tutorials » Ask-the-Experts Service » Buyer Blogs » White Papers » Endorsed Service Providers NEW: Supplier Blacklist No need to spend a lot of time on cultural differences Your cultural understanding is not a prerequisite for success Very forgiving of cultural mistakes So many examples …But there are a few things to be aware of Sourcing expectations: Domestic vs. international sourcing • Culture • Communication • • • • • • – time and language, spoken vs. written Travel Due diligence Contracts / PO’s Quality Product design (Harley example) Order quantities Sourcing expectations: Domestic vs. international sourcing • Lead times – custom production = 30 + 30 +30 – air vs. sea, container, spell it out down to BOM and confirm it… “put it in a box” is not the way to leave it • Packaging • Sampling – if not off shelf, may not be easy or free… short term thinking… relative value Sourcing expectations: Domestic vs. international sourcing • • • • • Payment Shipping/logistics Duties/tariffs Customs clearance Returns (build it into contract, order extra…) • Servicing • IP protection Sourcing expectations: Domestic vs. international sourcing • Legal exposure – Importer of record, who is to confirm conformance, why not let the supplier determine conformance • No “common knowledge” – If you can’t write it down and scientifically confirm it, you can’t expect it… example: color conformation Lots of challenges, but the payoff in savings is worth the effort “everything is possible, nothing is easy” Disclaimer on China Intellectual Property Vast majority of suppliers are honest and a pleasure to deal with. Unfortunately in a market as massive and competitive as China, IP is often a casualty. IP protection will be a key part of “Part 2” later in the week. Types of suppliers (vs. a “vendor”) Pros & cons • • • • • “Chinese Chinese” factory “FIE” Chinese factory WOFE JV (CJV, EJV, Fabricated JV) SOE Excerpts from White Paper “Avoiding Middlemen – what most China sourcing agents, trading companies and brokers don’t want you to know!” Testing a theory trade show in Mainland China stood in the main hall complex product said in English “can anybody here make this item” Result: 15 “mei wenti” (“no problem”), factory direct connections and great pricing. Today, the amount of money involved in the China Sourcing game is so large …..BUYER BEWARE. Factory Direct or Not? (Good vs. bad middlemen) 1. 2. 3. 4. 5. Costs Quality Plan for IP Project Management Communications “Check list of Red Flags” available via email Example #1: Two Faced Cards Example #2: Bait n Switch Ask for copy of license China QC Overview Why are China Quality issues always in the news? Recent and Rapid growth of Production Base Global Interaction made easy thanks to the Internet “know our limits and don’t rely solely on the suppliers” Let’s explore some of the key terms. Testing vs. Inspection vs. Audit Testing: In a lab. Lead Test for example. Inspection: Pulling a random sample from production line, warehouse or market place, to compare against agreed standards Audit: Two Main Kinds 1. Factory Audit= technically assessment of people, skills, process and equipment 2. Social Audit = child labor, min wage, OT, insurance, work place safety Golden Sample vs. Production Sample (how dangerous to ask “just give me a sample”) ISO: family of standards and guidelines for measuring quality in the manufacturing and service industries from the International Organization for Standardization (ISO). BUT ISO 9000 certification does not guarantee product quality. It ensures that the processes that develop the product are documented and performed in a quality manner. “ concrete life jackets” Quality Control: A system that is put in place by a manufacturer to monitor and maintain quality as goods flow from raw materials (IQC) into semifinished goods (IPQC) into finished goods ready and packaged for shipment (FQC). QA or 3PQC: Outside party that reviews the QC system of the factory and provides testing, inspection and/or audit services Minor vs. Major vs. Critical Defects Critical= could hurt somebody Major= ability to sell the product is compromised Minor= temporarily acceptable defect QC Fundamentals As we advance from Concept to Production to Delivery, the cost associated with testing and fixing any problems increase exponentially. You will see that a few simple steps, early on, not only are inexpensive, but very effective in reducing the exposure to nonconfirming products. FREE Tools 1. Do they have a Quality Manual? The QC toolbox “PQM” template available at www.PSSchina.com 2. Ask for references INEXPENSIVE Tools 1. Factory Audit Few 100 USD if using a 3rd party specialist like www.AsiaQualityFocus.com 2. Consider verification & investigation by specialist like www.CBIconsulting.com.cn 1. Shipping department at factory declares cargo ready 2. Engages export customs broker in China for clearance and inspection 3. China Customs allows export (based on license held by factory) 4. Chinese trucking company picks up cargo carries to HK border 5. Customs cleared for export into HK 6. Delivery to Port or Airport (CFS) 7. Export clearance of HK and booking with Airline / Shipping Line 8. 9. 10. 11. Arrival at destination port / airport Customs clearance Local trucking company to pick up cargo at port / airport Delivery to buyers warehouse / facility Involved parties: Factory/Vendor/Buyer (3) Customs in China/Hong Kong/Final Destination (4-5) Logistic companies: Trucker/Shipping Lines/ Forwarder/Broker (5-7) Total parties involved 12 – 15 Key Logistics Points Find the right partner Fast and Slow Air 2-7 days Fast and Slow Sea 15-30 days Intermodal 5 years ago vs. Today Goal of Payments Segment: Common pitfalls/best practices for documentation and terms of payment What to do when things go wrong. Lessons learned: “30-40-30” & Roadmaps Financial Exposure is really Quality Exposure Be careful if transferring funds to a private account or 3rd party trading company RMB accounts in near future Is the name on the bank account the same as the name on the PO and the same as the production site? Traditional Risk Financial due diligence (www.CBIconsulting.com.cn) Site visits (confirm vendor is a real manufacturer) State lead times & penalties in contract Jurisdiction Evaluate reward vs. risk (especially for initial production run) Payment Terms are not Incoterms PO & Contracts will be reviewed in separate seminar What to do when things go wrong? •Find the right supplier in the first place •K.C.C.C. (keep cool, communicate clearly) •Arbitration/ Mediation •Legal enforcement as last option (8-0 record at the moment) Options for lawyers in China www.ChinaSourci ngInfo.org/book Includes templates for PO, Supplier Contract, Factory Audits, QC guidelines, RFQ and more $150 USD online or $100 Cash at booth at trade show while supplies last If take away just two things… Spend the time to find the right partners for both manufacturing and service providers Inspection linked to a Payment Plan PassageMaker Email: MikeB@PSSchina.com Company: www.PSSchina.com China Sourcing Information Center www.ChinaSourcingInfo.org Blog: www.AnotherChinaBlog.com LinkedIn “Mike Bellamy China” Booth # 3G01