LTd Research and Production Company “Polytechnika” MANUAL of

advertisement

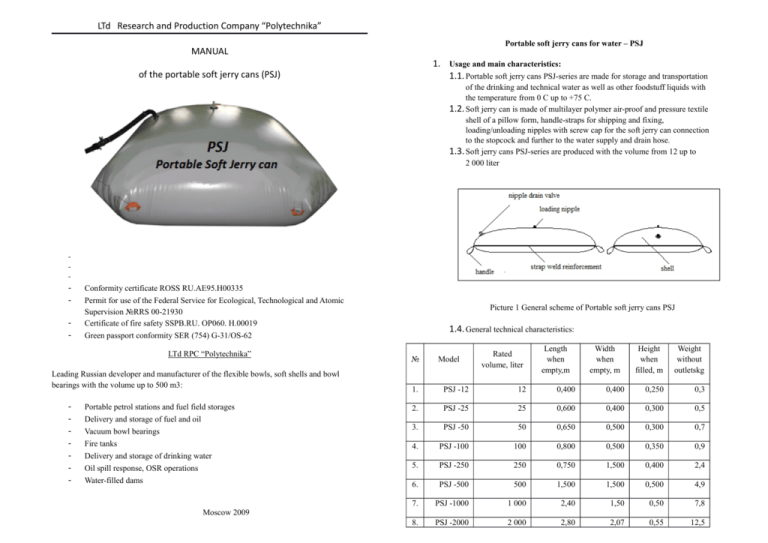

LTd Research and Production Company “Polytechnika” Portable soft jerry cans for water – PSJ MANUAL 1. Usage and main characteristics: 1.1. Portable soft jerry cans PSJ-series are made for storage and transportation of the portable soft jerry cans (PSJ) of the drinking and technical water as well as other foodstuff liquids with the temperature from 0 C up to +75 C. 1.2. Soft jerry can is made of multilayer polymer air-proof and pressure textile shell of a pillow form, handle-straps for shipping and fixing, loading/unloading nipples with screw cap for the soft jerry can connection to the stopcock and further to the water supply and drain hose. 1.3. Soft jerry cans PSJ-series are produced with the volume from 12 up to 2 000 liter - - Conformity certificate ROSS RU.AE95.H00335 Permit for use of the Federal Service for Ecological, Technological and Atomic Supervision №RRS 00-21930 Certificate of fire safety SSPB.RU. OP060. H.00019 Green passport conformity SER (754) G-31/OS-62 LTd RPC “Polytechnika” Leading Russian developer and manufacturer of the flexible bowls, soft shells and bowl bearings with the volume up to 500 m3: - Portable petrol stations and fuel field storages Delivery and storage of fuel and oil Vacuum bowl bearings Fire tanks Delivery and storage of drinking water Oil spill response, OSR operations Water-filled dams Picture 1 General scheme of Portable soft jerry cans PSJ 1.4. General technical characteristics: № Model Rated volume, liter Length when empty,m Width when empty, m Height when filled, m Weight without outletskg 1. PSJ -12 12 0,400 0,400 0,250 0,3 2. PSJ -25 25 0,600 0,400 0,300 0,5 3. PSJ -50 50 0,650 0,500 0,300 0,7 4. PSJ -100 100 0,800 0,500 0,350 0,9 5. PSJ -250 250 0,750 1,500 0,400 2,4 6. PSJ -500 500 1,500 1,500 0,500 4,9 7. PSJ -1000 1 000 2,40 1,50 0,50 7,8 8. PSJ -2000 2 000 2,80 2,07 0,55 12,5 Moscow 2009 3.1 Soft jerry can filling-in is should be made through the filling hose from the water supply system or with the help of hose (sleeve) or with the help of boot by hand from canister (bowl) up to the rated value shown in the technical passport (warranty). *on the customer’s request it is possible to manufacture PSJ with non-standard size **the sized are shown for jerry cans filled on the flat surface. When the jerry can is placed in the limited value (box), the size and value of the filled soft jerry can will be defined by the internal geometry of space taken. 2. Installation 2.1. Soft jerry cans are made for installation: - in living, back or housekeeping areas (lofts, cellars, etc.) - on the stands and supporting plans - in cabin, trunk and on-board of the transport means * During installation on the board of the transport mean the jerry can should be fixed with the strap (belt, tape) to exclude the possibility of its displacement during moving. 2.2. The surface for soft jerry can installation should be clean and without sharp things, which can damage the air-proof shell such as glass, nails, thorns, screws, wires etc. 2.3. Protuberances of the transport mean body should be prior covered with tent material or canvas. 3.2 During filling-in it is necessary to hold the neck of the filling hose with the handle and not let the upper shell to be under the lower and also to exclude the damage of the air-proof bearing because of boot, tap or other filling device. 3.3. It is not allowed to fill the soft jerry can more than the rated volume as well as the overflow through the neck of the filling hose 3.4. After filling-in the filling hose should be closed with the screw cap 3.5. To exclude the displacement and overrolling of the soft jerry cans it is necessary to fix them with the help of strap-handles to the body of the transport mean. 3.6. Filling and draining can be realized both of its own accord (if the level of the drain hose is lower than of the upper width of the soft jerry can shell) or with the help of rarefication made by pump with any placement of the soft jerry can. 3.7. The access of the natural air to the soft jerry cans (physical features of the flexible shells) is not required for draining. 2.4. When installing soft jerry cans in the limited space (set-in version) it is necessary to consider the capability of the box volume to the jerry can’s rated volume. 2.5. When installing jerry cans on the open ground it is recommended to protect the upper width of the jerry can’s shell from the long-term direct sunlight. 2.6. It is not allowed to heat the shell with the temperature higher than +80 C 2.7. Before the installation of the jerry can, it is required to connect the valve. To do this, you need to take off the lid from the drain vending and to connect valve with nipple winding PTFEtape. It is required to connect to the nipple valve and fix with the collar the hose (sleeve) of the appropriate diameter (valves and nipples do not include in the supply package) for connection to the distribution pipes or direct filling. 2.8 It is possible to make a direct loading from the jerry can without valve. In this case, it is required to lift the jerry can with the drain vending up, so the level of the drain vending will be above the liquid level, then open the lid and put down the vending draining the liquid as and when necessary. 4.Base-collector storage 4.1. If it is necessary to organize a volume storage, it is possible to connect several soft jerry cans in common system with the help of piping manifold. The group of jerry cans should have the same volume. 4.2. Output from valve of each bowl should be connected to the common piping manifold. 4.3. Collector’s pipe diameter should be not less than the diameter of the soft jerry can’s valve. 4.4 Filling and draining is made separately for each bowl (one by one) as per normal, the taps of the vacant bowls should be closed. 2.9. The filling hose of the soft jerry can should be on the top 2.10. If it is necessary, a nipple and a filling sleeve (do not include in the supply package) should be connected to the filling hose for output of the filling neck to the reachable place if the jerry can is placed in a closed or remote volume. 3. Filling and operation Picture 3. Collector installation scheme for the group of PSJ 5. Package and storage of empty soft jerry cans Manufacturer’s warranty 5.1 Empty soft jerry cans should be stored in closed space, on the open grounds under the cover or cover with tent material. Warranty life of the bowls – 1 year from the sale day, or, without the sellers stamp, 1 year from the manufacture day shown in the technical passport (warranty) 5.2 The best condition, which provides the minimum aging of the jerry cans is their storage in closed space with the temperature from -25 C up to +25 C and the humidity not higher than 70%/ 5.3. To prepare the jerry cans for storage: 5.3.1. Free the jerry can from any liquid sludge 5.3.2. Take off the valve, connected hoses and fully let the air out of the shell During the warranty life, it is allowed: - To store the bowls of all sizes when they are empty To store fuel (for PSJ and PER-B – water) in the bowls of all sizes Realizing installation, filling and draining of the fuel ((for PSJ and PER-B – water) Acts-reclamations are filled for bowls, which have defects before running out of the warranty of storage and operation, in case that the bowls were used according to the rules of this manual. Defects with which you can present act-reclamation to the manufacturer: 5.3.3. Put the screw cap on the draining hose 5.3.4. For wrapping the jerry can put on the flat surface, even it, then along the axial axis add it up at the knicklines (2) in three widths (3) overlapped, then add it up along the narrow axis at the knicklines (4) in a bad or roll. 5.3.5. During the shell add-up the draining hose should be opened for letting out the air. 5.3.6. During the full shell add-up the liquid sludge should be drained, then the draining hose should be closed with the screw cap. - Lack of air-proof in the shell width when pressing with extra air pressure up to 350 mm H2O Sweat, leakage, dropped dribbling and running through the shell and at the output bindings. Stratification of the seams without dribbling Shell break, seams stratification and other defects, appeared while using Noticing the defect, the user should send the bowl with defect to the manufacturer address with the bill or way-bill of the seller, including place and time of buying as well as written description of the defect. Bowls with defects will be changes for the new on in the warranty life limits. 5.3.7 The add-up bowl is placed into the case, which is included into the supply package. Warranty certificate Portable soft jerry can PSJ-____ Date of production: «___»__________200__ Date of air-proof test «___»__________200__ QC department controller_______________ Stamp Produced LTd RPC “Polytechnika” Adress^ 1110009383 Moscow, Shosseynaya st., 110-v Tel/Fax (495) 783-01-67. 783-01-68 Internet: URL: www.flexico.ru, Email: info@flexico.ru