Novas - Increasing signal visibility in FPGA-based - DSP

advertisement

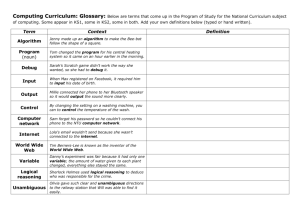

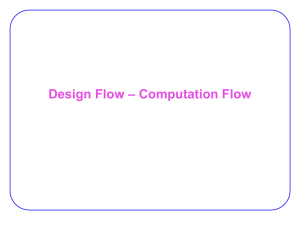

Special Feature Increasing signal visibility in FPGA-based prototypes By George Bakewell y l n O t n i r P e l g n i S r o F rototyping complex ASIC systems with emulation and FPGA prototypes requires hardware and software operating in tandem within embedded processor-based devices. While these methods provide greater verification bandwidth, their use creates issues with operational debug and analysis that can be addressed through new visibility enhancement techniques and tools. Inherent in silicon is the extremely limited signal access that hinders visibility into the internal workings of the device. FPGA debug methods such as “multiplexing to outputs” require significant resources to gain the smallest insight into the silicon. Internal Logic Analyzers (ILA) are structured, but are more suitable for understanding architectural registers rather than combinational logic. These methods require a “trial and error” approach since the engineer may not initially know what part of the design needs to be examined. By contrast, visibility-enhanced debug flow approaches such as those shown in Figure 1 automate the process of extracting and analyzing data to provide full observability. These approaches also ease FPGA debug through a series of steps: » Implement Design for Debug (DFD) logic in the FPGA to enhance the ability to retrieve crucial signal data. » Retrieve data while the FPGA is operating in-situ. » Map retrieved data to the RTL so the designer can understand the behavior. » Expand signal data by computing values that were not captured from silicon to enable deep analysis techniques. Optimal signal selection The first step in the process is to decide which signals need to be observed. Commercial ILA solutions – such as the ChipScope analyzer from Xilinx – usually consist of mechanisms to access internal signals and optional mechanisms for event triggering when the FPGA is operationally executing. This provides a way to bring out a limited set of internal signal values for observation, but leaves it to the user to determine the best points to observe. Visibility enhancement technology enables an analysis-driven approach that guides the observability decision process: » Determine the blocks and/or levels of hierarchy for observation. » Seed the process with a list the signals that must always be observed. Figure 1 www.DSP–FPGA.com Programmable Logic © 2007 OpenSystems Publishing Not for distribution Special Feature » Analyze the blocks to determine an optimal set of remaining signals that should also be observed to provide full visibility therein. » Provide the combined list of signals to the ILA insertion process. Visibility-enhanced signal selection also introduces the concept of “influence-ability” (the amount of downstream logic each signal influences). The design description and related code is analyzed in order to prioritize signal selection based on userprovided settings. The visibility-enhanced signal selection tool will first automatically identify any registers, memory elements, and primary I/Os that must be captured in order to observe the specified internal signals, and then round out the list based on available resources. graph-matching algorithms to generate a file that maps the gatelevel signals to the RTL. The map file can then be used with the RTL design and gate-level simulation results to correlate the captured signal data from one domain to the other. In Figure 2, the gates and values (shown on the left) are expanded and correlated to the corresponding RTL (right). This example shows that the ALU is performing an ADD function. Viewing unobserved values – data expansion Designers often want to display and analyze signals that were not in the captured set, and the retrieved data is typically limited to values from a set of registers. Data expansion techniques interpolate missing data by populating the signals internal to blocks of combinational logic that sit between registers whose signals were captured for that time-span in a cycle-accurate fashion. The expansion is done “on demand” only for the logic under investigation rather than statically for all design logic to maximize performance. y l n O t n i r P e l g n i S r o F “Value” proposition Retrieving signal values – data format With the observability logic in place, information required by downstream analysis and debug environments is automatically recorded during the verification run, including logic values, the full hierarchical instance name of the signal, and the relative operational times of any data transitions. In the event that there are not sufficient resources to capture all of the desired signals, the selection will be based on those signals that are deemed to have more influence as discussed above. The extracted data is then written to a file using an industry standard format such as the Value Change Dump (VCD) format or the popular Fast Signal Database (FSDB) from Novas that captures results from simulators and other verification tools through an open application programming interface. Viewing values at the RTL – mapping rules Data from ILAs is usually associated with the gate-level view of the FPGA, and not every signal in the gate-level representation will have a corresponding signal in the RTL. Visibility-enhancement techniques localize signal correspondence in order to represent low-level data at the RTL. One such technique is to automatically generate structural dependency graphs and employ approximate Advanced analysis Advanced debug techniques normally applied on software simulation results can also be applied to the FPGA results. For example, if the target device contains internal buses, the expanded data could be viewed at the transaction level, making it easier to understand the actual operation. Careful integration of the data expansion engine with the debug system could provide both time and file size reductions and enable automated, guided debug with its advanced analysis and tracing techniques (see Figure 3). Conclusion Visibility enhancement techniques for FPGA prototype and emulation of ASIC systems apply automation to the process of locating, isolating, and understanding the causes of errors. A small amount of upfront logic implementation provides silicon data access, while RTL mapping and data expansion enable full visibility using just the essential signal data. Combined with sophisticated debug engines, the net result of these techniques is faster debug of functional errors and system verification. George Bakewell is Director of Product and Technical Marketing at Novas Software, Inc. He is responsible for product management and technical direction of sophisticated design debug automation systems, and works closely with R&D on product specifications. He has presented at technical conferences, industry standard organizations, and personally conducted in-depth tutorials and application workshops. George has 20 years of experience in the EDA industry, and holds a BS in Electronic Engineering and Computer Science from the University of Colorado. Figure 2 Novas 2025 Gateway Place, Suite 400 San Jose, CA 95110 408-467-7888 Website: www.novas.com Figure 3 www.DSP–FPGA.com Programmable Logic © 2007 OpenSystems Publishing Not for distribution