Crystal Imperfections in Solids [7]

advertisement

![Crystal Imperfections in Solids [7]](http://s3.studylib.net/store/data/008311432_1-73ab0b6bbff880ea6e4c24d3e014fbc2-768x994.png)

Crystal Imperfections in Solids [7]

¾ Agregation of atoms (temperature decreasing):

vapour/gas

liquid

solid

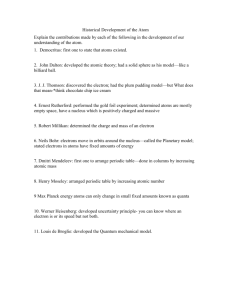

¾ Solidification: result of casting of molten material

• Step 1: Nuclei formation

• Step 2: Nuclei grow to form crystals – grain

structure

Schematic illustration of the stages during solidification of molten metal; each

small square represents a unit cell. (a) Nucleation of crystals at random sites in

the molten metal; note that the crystallographic orientation of each site is

different. (b) and (c) Growth of crystals as solidification continues. (d) Solidified

metal, showing individual grains and grain boundaries; note the different angles

at which neighboring grains meet each other.

1>

Strength of Materials

¾Based on the bond strength most materials

should be much stronger than they are.

¾The strength for a strong ionic bond should

be about 7 GPa …

… but more typical strength is 300 MPa !

¾Why do we have three orders of

magnitude difference?

Answer: Imperfections/defects in structure

2>

Crystal Imperfections in Solids

¾ The atomic arrangements in a crystalline

lattice is almost always not perfect.

¾ There are “defects” in the way atoms are

arranged in the crystalline solids.

¾ So we can say that in crystalline solids some

Lattice Irregularities are always present.

¾ These crystalline defects are not bad. Some

are intentionally introduced to improve the

material.

3>

Types of Crystalline Defects

¾ CRYSTALLINE DEFECTS: classified on the

basis of their geometry and dimensionallity.

¾ POINT DEFECTS (no dimensional)

¾ LINE DEFECTS (1D)

¾ INTERFACIAL/SURFACE DEFECTS (2D)

¾ VOLUME DEFECTS (3D)

4>

Classification of Defects Based on Dimensionality

0D

(Point defects)

1D

(Line defects)

2D

(Surface / Interface)

3D

(Volume defects)

Vacancy

Dislocation

Surface

Twins

Impurity

Interphase

boundary

Precipitate

Frenkel

defect

Grain

boundary

Voids /

Cracks

Schottky

defect

Twin

boundary

Stacking

faults

5>

Dimensional scale of defects

significant effect on mechanical properties

6>

Point Defects

¾ POINT DEFECT: Imperfect point-like regions in

the crystal about the size of 1-2 atomic diameters

Vacancy

Non-ionic

crystals

0D

(Point defects)

Ionic

crystals

Interstitial

Impurity

Substitutional

Frenkel defect

Schottky defect

7>

Point Defects

¾ Vacancy: missing atom from an atomic site

¾ Atoms around the vacancy displaced

¾ Tensile stress field produced in the vicinity

X

Tensile stress field of vacancy

8>

Vacancies

¾ Usually introduced during solidification, at high T

¾ The vacancy concentration in pure elements is very

low at low temperatures.

¾ The probability that an atomic site is vacancy ~ 10-6

at low temperature

¾ The probability that an atomic site is vacancy ~ 10-3

at melting temperature

¾ can affect physical and electronic structures around

them → influence properties like color, conductivity

¾ they play a critical role in diffusion: control the self

diffusion and substitutional diffusion rates

¾ Movements of atoms coupled with movements of

vacancies

9>

Vacancies Equilibrium of Point Defects

¾ Each lattice site is a potential vacancy site, so the

equilibrium number of vacancies formed as a result of

thermal vibrations may be calculated from thermodynamics.

¾ At equilibrium, the fraction of lattices that are vacant (or

vacancy concentration) at a given temperature is given

approximately by the equation:

n

(− G f / kT )

=e

N

¾ where n is the number of point defects (number of vacancy

sites) in N sites and Gf is free energy of formation of the

defects (vacancy), T is the absolute temperature, k is the

Boltzman constant (1.38 x 10-23 J/atom.K or 8.62 x 10-5 eV/atom.K).

¾ A large numbers of additional (non equilibrium) vacancies

can be introduced by thermomechanical processing.

10>

The Effect of Temperature on Vacancy Concentration

¾ Calculate the concentration of vacancies in FCC copper

at room temperature (25oC). Assume that 20,000 cal are

required to produce a mole of vacancies in copper.

Solution: The lattice parameter of FCC copper is 0.36151

nm. The number of copper atoms, or lattice points, per

cm3 is:

4 atoms/cell

22

3

n=

=

8

.

47

×

10

copper

atoms/cm

(3.6151×10 −8 cm) 3

At room temperature,

⎛ Qν ⎞

T = 25 + 273 = 298 K

nν = n exp⎜

⎟

⎝ RT ⎠

cal

⎛

⎞

20,000

−

⎜

⎟

⎛

22 atoms ⎞

mol

⎜

⎟

.

exp

= ⎜ 8.47 × 10

⎟

3

cal

cm ⎠

⎜ 1.987

⎟

⎝

×

298K

⎜

⎟

mol − K

⎝

⎠

8

3

= 1.815 × 10 vacancies/cm

11>

Impurities in Solids

¾ Pure metal, containing only one type of atoms,

is not possible.

¾ Impurity atoms are always present.

¾ These atoms exists as point defects.

¾ In alloys, impurity atoms (alloying element

atoms) are intentionally added.

¾ An alloy is usually a solid solution of two or

more types of atoms.

¾ Examples:

Fe + C = steel

Cu + Zn = brass

Ni + Cu = monel

Al + Cu = dural

12>

Types of Solid Solutions

¾ SUBSTITUTIONAL IMPURITY

• Foreign atom replacing the parent atom in the crystal

• E.g. Cu sitting in the lattice site of FCC-Ni

¾ INTERSTITIAL IMPURITY

• Foreign atom sitting in the void of a crystal

• E.g. C sitting in the octahedral void in HT FCC-Fe

SUBSTITUTIONAL

Tensile Stress Fields

INTERSTITIAL

Compressive Stress Fields

13>

Hume-Rothery Rules for Solid Solution

¾ Hume-Rothery (1899-1968) states 4 Conditions

that must be satisfied for obtaining large solubility

of the substitutional solute in a given solvent lattice:

1.

2.

3.

4.

¾

Atomic Size Factor: The atomic size difference between

the solute and solvent atoms must be less than ± 15%.

Crystal Structure: Crystal structure of both solute and

solvent must be same.

Electronegative: The difference must be small. If this

difference is large ionic compound will form instead of

solid solution.

Valence: Higher valence metals will dissolve easily than

low valence metals.

When one or more is violated, partial solubility is

obtained.

14>

Hume-Rothery Rules for Solid Solution

¾ Ni + Cu: will they have large Solid Solubility?

Checking 4 H-R rules …

rule

Atomic Size

Ni

Cu

0.125nm 0.128nm

Crystal structure

FCC

FCC

Electronegativity

1.8

1.9

Valence

+2

+1

Answer: Yes, they will total solubility.

15>

Hume-Rothery Rules for Solid Solution

¾ Zn + Cu: will they have large Solid Solubility?

rule

Zn

Checking 4 H-R rules …

Atomic Size

Cu

0.133nm 0.128nm

Crystal structure

HCP

FCC

Electronegativity

1.6

1.9

Valence

+2

+1

Answer: No, they will not (partial solubility).

16>

Carbon Solid Solution in Iron

In FCC iron, carbon atoms are located at octahedral

sites. In BCC iron, carbon atoms enter tetrahedral

sites which are larger than octahedral ones. What

would be the atomic percentage of carbon in each

type of iron if all the interstitial sites were filled?

SOLUTION: We can find a total of 12 tetrahedral interstitial sites for

BCC structure. If all sites of BCC cell are occupied atomic

percentage of carbon in BCC iron would be:

The number of octahedral interstitial sites is 4 interstitial sites per

FCC unit cell. So, the atomic percentage of carbon in FCC iron

would be:

17>

Carbon Solid Solution in Iron

Interstitial C sitting in the octahedral void in HT FCC-Fe

rOctahedral void / rFCC atom = 0.414

rFe-FCC = 1.29 Å

rC = 0.71 Å

⇒

rOctahedral void = 0.414 x 1.29 = 0.53 Å

⇒ Compressive strains around the C atom

Solubility limited to 2 wt% (9.3 at%)

Interstitial C sitting in the tetrahedral void in RT BCC-Fe

rTetrahedral void / rBCC atom = 0.29 • rC = 0.71 Å

⇒

rTetrahedral void = 0.29 x 1.258 = 0.364 Å

rFe-BCC = 1.258 Å

► But C sits in smaller octahedral void - displaces fewer atoms

⇒ Severe compressive strains around the C atom

Solubility limited to 0.008 wt% (0.037 at%)

18>

Specification of Composition or Concentration

m1

x 100

– WEIGHT PERCENT C1 =

m1 + m2

(wt%)

n m1

x 100

C =

n m1 + n m 2

(at%)

– ATOM PERCENT

being

'

1

m1

nm1 =

A1

m = mass; n = moles (atoms) - Compositions are easily converted from one

type to the other by manipulating m to n, or vice versa, using the atomic weight,

“A”.

19>

Specification of Composition or Concentration

¾ Example: Determine the composition, in atom percent, of

an alloy that consists of 97 wt% aluminum and 3 wt% copper.

(number of Al atoms)

C Al =

(number of Al atoms) + (number of Cu atoms)

(mass of Al atoms)

(number of Al atoms) =

(atomic weight of Al)

(97g Al)

(number of Al atoms) =

= 3.595 mol Al

(26.98 g/mol Al)

(3g Cu)

(number of Cu atoms) =

= 0.047 mol Cu

(63.55 g/mol Cu)

3.595

C Al =

= 98.7%at Al

C Cu = 100 - C Al = 1.3%at Cu

3.595 + 0.047

20>

Solid Solution Strengthening in Steels

Interstitial solute

Substitutional

solute

21>

Point Defects in Ceramics

¾ Vacancies

-- vacancies exist in ceramics for both cations and anions

¾ Interstitials

-- interstitials exist for cations

-- interstitials are not normally observed for anions because

anions are large relative to the interstitial sites

Cation Interstitial

Cation Vacancy

Adapted from Fig. 5.2, Callister & Rethwisch 3e.

(Fig. 5.2 is from W.G. Moffatt, G.W. Pearsall, and

J. Wulff, The Structure and Properties of

Materials, Vol. 1, Structure, John Wiley and Sons,

Inc., p. 78.)

Anion Vacancy

22>

Point Defects in Ceramics

¾ Frenkel Defect

To maintain the charge neutrality, a cation vacancy-cation

interstitial pair occur together. The cation leaves its normal

position and moves to the interstitial site.

23>

Point Defects in Ceramics

¾ Schottky Defect

To maintain the charge neutrality, remove 1 cation and 1 anion;

this creates 2 vacancies.

24>

Point Defects in Ceramics

¾ Since there are both anions and cations in ceramics, a substitutional

impurity will replace the host ion most similar in terms of charge.

¾ Charge balance must be maintained when impurities are present.

• Example: NaCl

Na +

Cl -

• Substitutional cation impurity

Ca2+

Na+

Na+

without impurity Ca2+ impurity

• Substitutional anion impurity

O2-

without impurity

ClClO2- impurity

cation

vacancy

Ca2+

with impurity

anion vacancy

with impurity

25>

Semiconductor Ceramics

¾ Intrinsic semiconductor - A semiconductor in

which properties are controlled by the element or

compound that makes the semiconductor and not

by dopants or impurities.

¾ Extrinsic semiconductor - A semiconductor

prepared by adding dopants, which determine the

number and type of charge carriers.

¾ Doping - The addition of a small percentage of

foreign atoms in the regular crystal lattice of

silicon or germanium produces dramatic changes

in their electrical properties, producing n-type and

p-type semiconductors.

26>

Extrinsic Semiconductor

¾ Semiconductor N-type: The addition of pentavalent impurities such as Antimonium, Arsenic or

Phosphorus contribute free electrons, greatly

increasing the conductivity

of the intrinsic semiconductor.

Donor impurities:

¾ Sb

¾ As

¾P

27>

Extrinsic Semiconductor

¾ Semiconductor P-type: The addition of trivalent

impurities such as Boron, Aluminium or Gallium to an

intrinsic semiconductor creates deficiencies of

valence electrons, called "holes".

Acceptor impurities:

¾B

¾ Al

¾ Ga

28>

Point Defects

29>

Linear Defects

¾ Dislocations are linear defects and represent a line

around which atoms in the crystalline lattice are

misaligned.

¾ Types of Dislocations:

¾ EDGE DISLOCATION: A dislocation introduced into

the crystal by adding an ‘‘extra half plane’’ of atoms.

¾ SCREW DISLOCATION: A dislocation produced by

skewing a crystal so that one atomic plane produces a

spiral ramp about the dislocation.

¾ “MIXED” DISLOCATION: A dislocation that contains

partly edge components and partly screw components

30>

Edge Dislocation

Burgers vector b ⊥ dislocation line

b

Shear stress

Compressive stress field is colored RED and tensile stress field is BLUE.

31>

Screw Dislocation

Burgers vector b || dislocation line

Shear stress

Dislocation

line

Burgers

vector b

b

Top view

There are not compressive or tensile stress fields associated to screw

dislocation, only pure shear around dislocation line.

32>

Edge, Screw, and Mixed Dislocations

Mixed

Edge

Screw

During sliding Burgers vector does not change.

33>

Burgers Vector

¾ Burgers Vector b represents the magnitude and

direction of lattice distortion created by the dislocation.

– EDGE DISLOCATION b is perpendicular to dislocation

– SCREW DISLOCATION b is parallel to dislocation

34>

Slip Systems

¾ Dislocations move more readily in some crystal planes and

directions than in others as we will see.

¾ The combination of both the slip plane and direction form the

slip system.

¾ Slip plane is generally taken as the closest packed plane in the

system. Slip direction is taken as the direction on the slip

plane with the highest linear density.

¾ The line direction of a screw dislocation is in the same

direction as its Burger’s vector.

¾ An edge dislocation has its Burger’s vector perpendicular to

the line direction of a dislocation

¾ A dislocation having a line direction not parallel or

perpendicular to the Burger’s vector is considered a mixed

dislocation.

35>

Schematic of Dislocation Slip

Edge dislocation

Screw dislocation

36>

Slip Systems for Dislocations

Examples of slip plane

and direction for BCC

37>

Burgers Vector Calculation

¾ Calculate the length of the Burgers vector in copper.

SOLUTION: Copper has an FCC

crystal structure. The lattice

parameter of copper (Cu) is

0.36151 nm. The close-packed

directions, or the directions of the

Burgers vector, are of the form

<110>. The repeat distance along

the directions is one-half the face

diagonal, since lattice points are

located at corners and centers of

faces.

The length of the Burgers vector, or the repeat distance, is:

b = 1/2(0.51125 nm) = 0.25563 nm

38>

Formation of Dislocations

¾ Frank-Read sources:

Dislocations propagating

on slip plane from a

Frank-Read source

Two atractive

Frank-Read

interacting

Two repulsive

Frank-Read

interacting

http://www.numodis.fr/tridis/

39>

http://www.numodis.fr/tridis/

Dislocation Motion and Interaction

dislocations moving through a forest of dislocations

40>

http://www.numodis.fr/tridis/

Dislocation Motion and Interaction

pile-up at a grain boundary and overcoming it.

41>

http://www.numodis.fr/tridis/

Dislocation Motion and Interaction

dislocation multiplication and transmission in a bicrystal

42>

http://www.numodis.fr/tridis/

Dislocation Motion and Interaction

dislocation bowing a spherical particle.

43>

Dislocation Motion and Interaction

Mobility of an edge dislocation with different kinds of solute atoms

44>

Observing Dislocations in Thin Foils

¾ Dislocations can be observed in thin foil samples,

a very thin piece of material (< 100nm), which

be able to diffract a high voltage accelerated electron

beam of a transmission electron microscope (TEM).

(c) 2003 Brooks/Cole Publishing / Thomson Learning

top view

side view

TEM micrograph

45>

Observing Dislocations in Thin Foils

Source: http://www.numodis.fr/tridis/TEM/index.html

46>

Interfacial Defects

¾ INTERFACIAL DEFECTS are boundaries that have 2 or 3

dimensions and normally separate regions of the materials

that have different crystal structures and/or crystallographic

orientations.

¾ EXTERNAL SURFACES: One of the most obvious

imperfection boundaries is the external surface because the

crystal structure terminates.

¾ Surface atoms are not bonded to the maximum number of

nearest neighbors so they have higher energy state than

interior atoms.

¾ INTERNAL SURFACES:

¾ grain boundaries

¾ twin boundaries

¾ Stacking faults

¾ Of all these, the grain boundaries are the most important

from the mechanical properties point of view.

47>

Grain Structure

Crystalline solids generally consist of millions of individual

grains separated by boundaries. Each grain is a single crystal.

Within each individual grain there is a systematic packing of

atoms. Therefore each grain has different orientation and is

separated from the neighboring grain by grain boundary.

grain

grain boundary

48>

Polycrystalline Materials

¾ At the grain boundary, there is a disturbance in the

atomic packing.

HAGB: θ > 15 degrees

49>

Polycrystalline Materials

HALL-PETCH:

Small grain size

equates

to more strength

Hall-Petch mechanism: dependence of strength on grain

size for a number of metals and alloys.

50>

Grain Growth: Simulations in 2D & 3D

https://www.youtube.com/watch?v=J_2FdkRqmCA

https://www.youtube.com/watch?v=Ac_ca_NeRnw

51>

Tilt Boundary

¾ The simplest grain boundary consists of

a configuration of edge dislocations

between two grains.

¾ The misfit in the orientation of the two

grains (one on each side of the boundary)

is accommodated by a small perturbation

of the regular arrangement of crystals in

the boundary region.

¾ Schematic shows some vertical atomic

planes termination in the boundary and

each termination is represented by an

edge dislocation.

52>

Twist Boundary

¾ When the angle of

misorientation is parallel to

the boundary due to an array

of screw dislocations.

53>

Twin Boundary

¾ A twin boundary is a special type of grain boundary across

which there is a specific mirror lattice symmetry. Twin results

from atomic displacement that are produced from applied

mechanical shear forces, and also during annealing heat

treatments following deformation (annealing twins).

Twinning (FCC): {111} <211>

http://practicalmaintenance.net/?p=1135

54>

Comparison

Slip

Twinning

orientation of atoms

remains the same

reorientation of atomic

direction across twin plane

displacements take place atomic displacement is less

in exact atomic spacings than interatomic spacing

55>

Stacking Faults

¾ Error in packing sequence:

SF

perfect

defect

56>

Stacking Faults

¾ Bright Field Image in TEM:

http://www.tf.uni-kiel.de/matwis/amat/def_en/kap_6/backbone/r6_3_3.html

57>

Bulk or Volume Defects

¾ Much larger defects than the previous ones,

usually introduced during processing and

fabrication steps

¾ Examples include:

– Pores

– Cracks

– Foreign Inclusions

– Other Phases

Stress-corrosion cracking of na Inconel heat exchanger tube.

58>

References

¾ CALLISTER JR, W. D. AND RETHWISCH, D. G.

Materials Science and Engineering: An Introduction, 9th edition.

John Wiley & Sons, Inc. 2014, 988p. ISBN: 978-1-118-32457-8.

¾ ASHBY, M. and JONES, D. R. H.

Engineering Materials 1: An Introduction to Properties, Applications and Design.

4th Edition. Elsevier Ltd. 2012, 472p. ISBN 978-0-08-096665-6.

¾ CALLISTER JR, W. D. AND RETHWISCH, D. G.

Fundamentals of Materials Science and Engineering: An Integrated Approach, 4th ed.

John Wiley & Sons, Inc. 2012, 910p. ISBN 978-1-118-06160-2.

¾ MITTEMEIJER, E. J.

Fundamentals of Materials Science: The Microstructure–Property Relationship Using

Metals as Model Systems. Springer-Verlag Berlin. 2010, 594p. ISBN 978-3-642-10499-2.

¾ ASKELAND, D. AND FULAY, P.

Essentials of Materials Science & Engineering, 2nd Edition.

Cengage Learning. 2009, 604p. ISBN 978-0-495-24446-2.

¾ ABBASCHIAN, R., ABBASCHIAN, L., AND REED-HILL, R. E.

Physical Metallurgy Principles, 4th Ed. Cengage. 2009, 750p. ISBN 978-0-495-08254-5.

¾ SMALLMAN, R. E. and NGAN, A.H.W.

Physical Metallurgy and Advanced Materials, 7th Edition.

Elsevier Ltd. 2007, 650p. ISBN 978-0-7506-6906-1.

¾ http://www.tf.uni-kiel.de/matwis/amat/def_en/

Nota de aula preparada pelo Prof. Juno Gallego para a disciplina Ciência dos Materiais de Engenharia.

® 2015. Permitida a impressão e divulgação.

http://www.feis.unesp.br/#!/departamentos/engenharia-mecanica/grupos/maprotec/educacional/

59