Effective document control is key to capital

advertisement

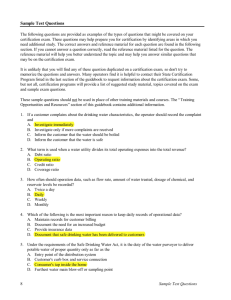

AS SEEN IN SEPTEMBER 2012 OPERATING EFFICIENCY Effective document control is key to capital project success Successful processes can allocate risk and control a project’s value chain. Mark Goodwin, McLaren Software D espite the slow global economic growth and the recent decline in oil and gas prices, major capital project investment appears very much on the rise. DouglasWestwood, for example, forecasts a 90% growth in deepwater expenditure between 2012 and 2016, and a recent report from Infield Systems predicts a 50% increase in pipeline capex over the next five years. It is the proliferation of such huge, complex, and expensive projects that bring with them significant challenges – particularly in relation to the control of documents. Document control is about ensuring that all documentation and business processes adhere to business, contractual, safety, and regulatory rules and is crucial to ensuring the successful outcome of these major capital projects. Document control is about the processes and should not be confused with document management, which is the mechanics of creating, reviewing, storing, and publishing documents. It’s about creating an environment of transparency and visibility so operators and the construction management consortiums they contract with can track the thousands of project-related documents, ensure that all regulatory requirements are met, manage corporate risk, and ensure the eventual successful handover of the project. Fifteen years ago, only 10% of large oil and gas projects ran more than 50% over budget; in 2011 this figure had doubled to 20%, according to a Schlumberger Business Consulting report. One reason for this is a failure to put in place adequate document control practices. While having a predominantly internal system often takes care of integration with existing internal processes, it often lacks the necessary scalability to expand as more and more vendors come onboard and projects become more complex. It also can put increased pressures on internal resources. One option is to select a generic document or enterprise content management platform and engage external resources to customize the system to match internal processes – an exercise that can become expensive and cumbersome. An expert in document management technology is not necessarily an expert in the industry-specific document control processes required to support a major capital project. Using document management as a blank canvas can lead to spiralling costs as the team learns the business requirements on the job and at the expense of the customer. On the other extreme, some project owners take a completely different approach to document control and fully outsource their information and document control systems hosted in the Cloud. While the Cloud brings with it clear benefits, there are potential downsides to this approach as well. These include the difficulty of integrating Cloud-based systems with enterprise asset information, maintenance repair and operation, or enterprise resource planning systems. There are also the security implications of outsourcing a company’s own entire document control system and the difficulties of collating and controlling the data ready for project handover. Finding middle ground Document control strategy prerequisites Some project owners tend to focus on building their own internal document control systems. These often consist of an in-house document control team logging the arrival of information, capturing it electronically in a central database, and then disseminating it to the relevant parties around the organization. Many such systems are databasedriven, supported by spreadsheets and requiring significant manual intervention. There are a number of disadvantages to such systems. More operators are now procuring purpose-built, commercially available project document control applications designed to take advantage of generic document or enterprise content management platforms. This is a buildvs.-buy approach where 80% of the requirements are provided for in the application and the remaining 20% can be achieved by configuration of the application rather than customization of the platform. This approach strikes a balance between on-premise systems capable of tight integration with existing systems and September 2012 | EPmag.com OPERATING EFFICIENCY Cloud-based project collaboration systems, where an operator can ensure consistent processes are followed by all members of the supply chain without the risk of exposing internal systems and networks. Hosting the system Certainly Cloud-based applications have a key role to play here, providing a single platform where project engineers can enjoy realtime collaboration across different projects and access information from a single, truly scalable system. It also is important to be clear as to the distinction between public and private clouds. Whereas a public cloud is open to a largely unrestricted universe of potential users, a private cloud can be restricted to a single company with the same level of security put in place as one would for internal IT servers. One such example of configuration, “light customization,” and obtaining the right balance between outsourced software and processes and existing internal resources, was a solution McLaren recently delivered for a major oil sands operator. Here the business challenge was to manage and control documentation from project startup to operations involving 2 million drawings and an additional 1,000 drawings produced per month, 1,600 users, and access for 57 contractors based worldwide. In this case, an enterprise-wide document control system was provided where each business unit had responsibility for its own documentation and management, a formal squad check was put in place to check all design and construction documents, secured access was provided to contractor personnel, and the management of sealed master drawings was implemented in line with government regulations. Successful document control processes can allocate risk and COPYRIGHT © control the project’s value chain, help develop multicontractual packages, integrate the requirements of the project management and engineering teams, ensure regulatory compliance, and create an auditable record of what was sent, to whom, when, for what purpose, and in what context. The dangers of going on vacation he figure illustrates how a major capital project can go off track because of a lack of communication and the absence of strong document control procedures. In this example, it concerns a replacement pump on an offshore field. The initial steps involve the “Transmittal to Request revision to Pump documentation,” which is passed from the document controller at the operator to the engineer/CAD designer at the contracting company. The pump documentation is revised and sent for acceptance with the operator via its document controller and then to the operator’s engineer. At this stage, the process has been closely managed, with cumulative costs of only US $10,000. Then the engineer at the operating company went on vacation. With 10 days having passed, the contractor assumed that the documentation had been approved and the pump was procured based on the approved design. The pump was then delivered to site with costs of $62,000. The pump, however, was found to be incompatible with the pump fittings, the documentation was sent back for review, and new fittings were ordered. The delays to the next stage of the pump system were calculated at $100,000/day, with cost overruns of $800,000. n T HART ENERGY | 1616 S. VOSS, STE. 1000, HOUSTON, TX 77057 USA | +1 713 260 6400 | FAX +1 713 840 8585