Impurities and classification - Chemical Hazards Communication

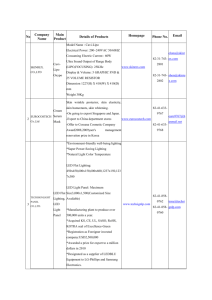

advertisement

Impurities and classification Mark Selby Denehurst Chemical Safety Ltd mark.selby@denehurst.co.uk www.denehurst.co.uk Denehurst Chemical Safety Ltd 1 Why classification ? The purpose appears to be either to allocate specific classification criteria to a substance or to communicate potential hazards to users 1. Entry to C & L Inventory (Notification) or Registration 2. Presentation of SDSs and labelling and for transport Can these acts be considered together or should they be separated ? Denehurst Chemical Safety Ltd 2 CLP Notification / Registration € Need to be sure that the substance with the defined EC number is correctly assessed for hazard and the appropriate classification assigned € Testing may be performed on the pure substance € If varying results within an endpoint from different sources of materials, can the differences be explained € Can the substance described in 1.1 of IUCLID be properly assessed using reliable data BUT.... Impurity details must be known Denehurst Chemical Safety Ltd 3 Equivalence ? For registration, it is necessary to understand if data set is applicable to your substance € Is the declared composition / purity / impurity data ‘equivalent’ to the material used for testing € Equivalence can be used for sameness or read-across € Have any impurities impacted on potential hazard ? € Declared in Section 1.2 of IUCLID and on CLP Notification € Different grades may be identified to recognise different constituents in UVCB or multi-constituent substance € These ‘grades’ need to be linked with multiple classifications € When each grade is supplied, its identity must be made clear in terms of which grade is being supplied Denehurst Chemical Safety Ltd 4 Classification for supply The labelling and SDS for material being supplied must match what is in container Mixtures and impure substances can be treated the same way € Classification is sum of hazards from pure substance and the hazards of impurities € Apply same criteria as for mixtures € Suppliers are not expected to test mixtures € Therefore, are your expected to test impure substances ? Denehurst Chemical Safety Ltd 5 Conflicting purity If two or more SIEF members have different purity range / impurity content € € They should try to agree on range for registration They must agree if studies are valid on the purities € Agreed classification should be for pure specification* € If material contains hazardous impurities, make estimation of classification for supply based on same principles as mixtures * For UVCB, multiple grades with multiple classifications may be the only way to agree; otherwise, SIEF splits and different substances registered. Denehurst Chemical Safety Ltd 6 Conclusions Classifications for inventory (and therefore if Notified under CLP or when registered) should be for pure material if possible to determine € € Same as applied to Annex I of 67/548/EEC and Annex VI of CLP For UVCB, different grades may be applied to each be given classification € € As with ‘notes’ in Annex I of 67/548/EEC for petrochemicals For supply and transport, the impurity may influence classification and labelling € € Treat like mixtures and identify hazardous impurity on label / SDS It will take years for harmonised classification to be finalised – if ever ! Denehurst Chemical Safety Ltd 7