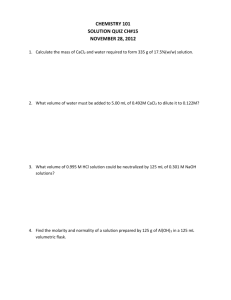

calcium chloride — winter de-icing

advertisement

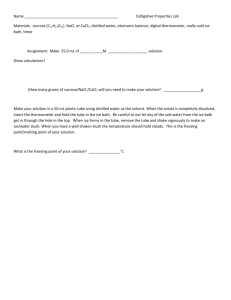

CALCIUM CHLORIDE — WINTER DE-ICING Chemical de-icing involves applying chemical agents such as sodium chloride (rock salt) and calcium chloride to lower the freezing point below 0oc. By spreading suitable chemicals on the road it is possible to: Prevent frost, ice or layers of ice from forming Melt existing snow, ice etc Prevent snow adhering to the road surface Rock salt (NaCl) has for many years been the main chemical agent used for de-icing in countries with relatively mild winters. However, where winter conditions can be more extreme, calcium chloride (CaCl 2) in liquid or solid form is used as the de-icing agent. Increasingly today, pre-wetted salt, a combination of NaCl and CaCl2 liquid, is finding application. CONDITIONS REQUIRED TO MELT SNOW AND ICE Moisture for the salt to dissolve Energy (heat) for the melting process A salt concentration lower than the eutectic value For all the above required elements CaCl2 is more beneficial than NaCl. CaCl2 is considerably more hygroscopic than NaCl, absorbing moisture from the air and this factor in conjunction with the exothermic reaction between CaCl2 and water results in a much more rapid snow/ ice melting rate. The eutectic temperature for CaCl2 is –51.6oc compared to –21.1oc for NaCl which means that CaCl2 can be used at lower temperatures. CALCIUM CHLORIDE — WINTER DE-ICING ADVANTAGES OF CaCl2 Faster initial melting of ice Remains active for longer, preventing re-occurrence of icing Effective to much lower temperatures Increases the effectiveness of NaCl Savings can be made by reduction in materials More effective at a wider range of humidity levels PREWETTED SALT By „prewetting‟ NaCl with a CaCl2 solution the advantageous properties of CaCl2 can be utilised to improve the performance of NaCl. Prewetting of NaCl can principally be carried out in two ways (1)The solution can be sprayed before spreading is started, ie. when loading the truck with salt. or alternatively, (2) prewetting takes place during spreading, where the truck has demountable tanks containing the CaCl2 solution which is sprayed onto the NaCl at the spreader plate. Prewetting of NaCl overcomes one of its major drawbacks “bounce and scatter”, where the NaCl is dispersed in all directions and only a fraction retained on the treated surface. Work undertaken in the 1970‟s showed that less than 50% of dry NaCl was actually retained in the centre of the road. Salt Retrieved from Treated Road 24ft in Width 80 60 Dry % 40 Prew et 20 0 Centre 1/3 Outer 2/3 Unretrieved Calcium Chloride Solution for Prewetting The addition rate is typically 1:3, CaCl2 : NaCl, and the CaCl2 solution strength may vary from 2030% dependent upon the prevailing temperature. The eutectic point for a 30% CaCl2 solution is approximately –51oc, which means that this solution would be most advantageous for prewetting at extremely low temperatures. In the UK a 20-25% CaCl2 solution would be more applicable. ADVANTAGES OF CaCl2 FOR PREWETTING Effective to lower temperatures Improved road adhesion Faster melting action Better spreading pattern Reduced quantity of salt (NaCl) required Less frequent passes required Cost savings on fuel CALCIUM CHLORIDE — WINTER DE-ICING DILUTION OF CALCIUM CHLORIDE SOLUTION The following formula can be used for dilution calculations: V = 100H (A-B) B Where V = Volumes of water to add to each 100 volumes of original CaCl2 solution A = % CaCl2 in the original solution B = % CaCl2 required in the final diluted solution H = Specific Gravity of the original solution Example: To prepare a 20% CaCl2 solution from a 36% CaCl2 solution with a specific gravity of 1.36 Substituting in the formula: V = 100 x 1.360 (36-20) 20 = 108 volumes Therefore 108 volumes of H2O added to 100 volumes of 36% CaCl2 solution will result in 20% CaCl2 solution. The above result may be expressed in gallons, cubic feet, cubic metres or any other volume unit. All information given is believed to be accurate. However, no representation or guarantee, express or implied, is made as to its completeness, accuracy, fitness for a particular purpose or any other matter, including without limitation, that the practice or application of any such information is free of patent infringement or other intellectual property misappropriation. All information provided herein is intended for use by persons having the requisite experience, knowledge and skill. Tata Chemicals Europe Limited shall not be responsible or liable for the use, application or implementation of the information provided.